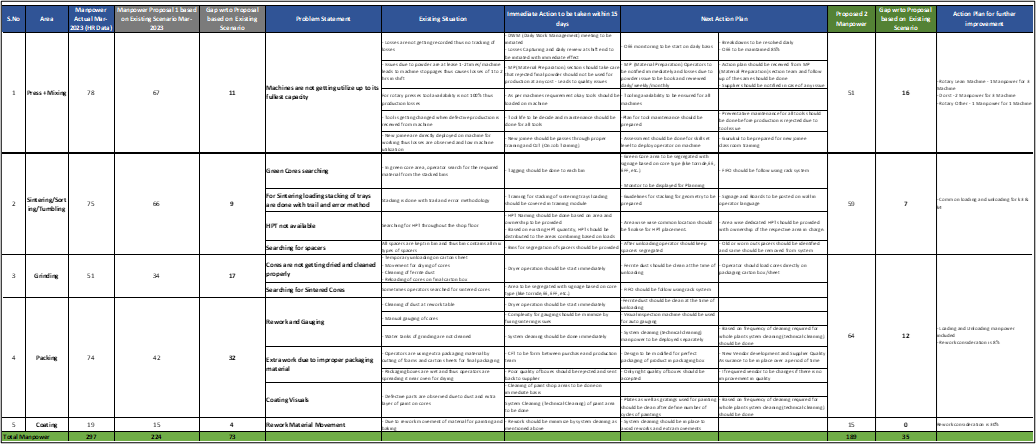

Key Challenges

Although an experienced manufacturer, the customer had quite a number of operational hurdles:

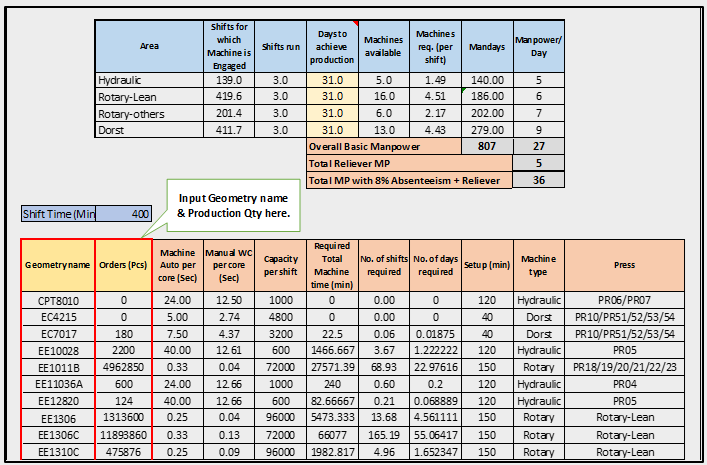

- Assess the overall system capacity and verify if targets for production could be achieved.

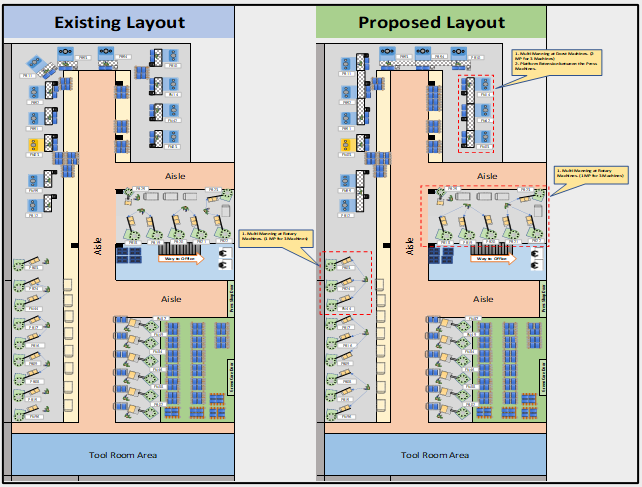

- Determine the likely bottlenecks that impact flow and efficiency.

- Examine the influence of unscheduled downtimes and maintenance interruptions.

- Determine the interaction and interdependencies between various zones of downtime.

- Calculate the buffer capacity required between zones to facilitate smooth operations.