Streamlining Capacity and Resources Optimization in Agriculture Machinery/Equipment Manufacturing Industry

Client Organization is an Agri-equipment entity with a goal focused on bettering the lives of farmers across India, with affordable mechanisation solutions. The company believes that the life of a farmer in India can truly change only when he can gain maximum growth from his inputs. The company’s affordable mechanization solutions, aim to achieve this task. The tractor industry is a complex industry which involves several actors who practice optimization at different levels. It would be interesting to understand the phenomenon from the perspective of the Big Agri’s since they are the main drivers of change in the innovation ecosystem of the industry, leading us to the goal of this case study.

Key Points

- Manpower utilization increased from 45% to 85%

- Capacity Expansion Study done to increase existing production capacity from 0.5 product per day to 1/day, 2/day & 3/day.

- Resources (Manpower and Machine) calculation using PMTS technique for different production scenarios.

- To increase productivity

- Eliminating waste and nonvalue-added activities.

Client's Challenge

- Production Demands

- Capacity Expansion to achieve 1/day, 2/day and 3/day production

- VA/NVA/E-NVA findings and optimization.

- Paint Shop, Pre-Painting & Post-Painting Area.

- Deployment of Manpower to achieve goals.

PMI's Approach

The study was organized in a 3-stage process:

- Data Collection.

- Data Analysis and Estimation.

- Results and Conclusion.

Data Collection – Collection of data from client in videos by visiting client site and then organizing the data for analysis and estimation after validation from client.

Data Analysis – Using the tools like PMTS Techniques, VA-NVA analysis, Excel Simulation and Stage Balancing for data analysis.

Results and Conclusion – Optimization of Work force, Areas for removal of non-value-added activities, Proposed Layout for execution of goals, stage balancing and simulation, Action plan for further improvements.

Involvement of Associates –

- PMI – 1 Project Manager, 3 Engineers.

- Client – 2 Project coordinators.

Data Collection:

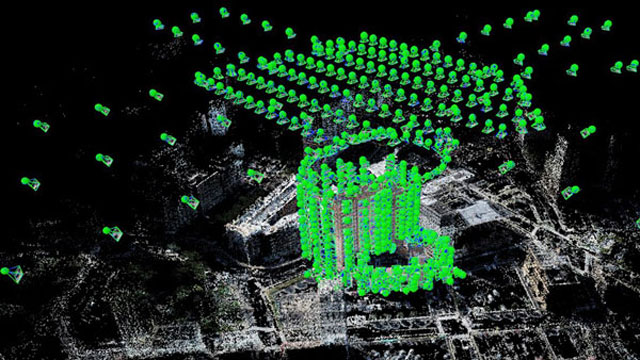

- On-site visit - Visiting Facility by PMI team for data collection.

- Understanding Process - Understanding processes & data collection from client.

- Video Shooting - Video shooting & observation of machine as well as manual activities.

- Video Sharing - Sharing of videos with client by PMI.

Data Analysis:

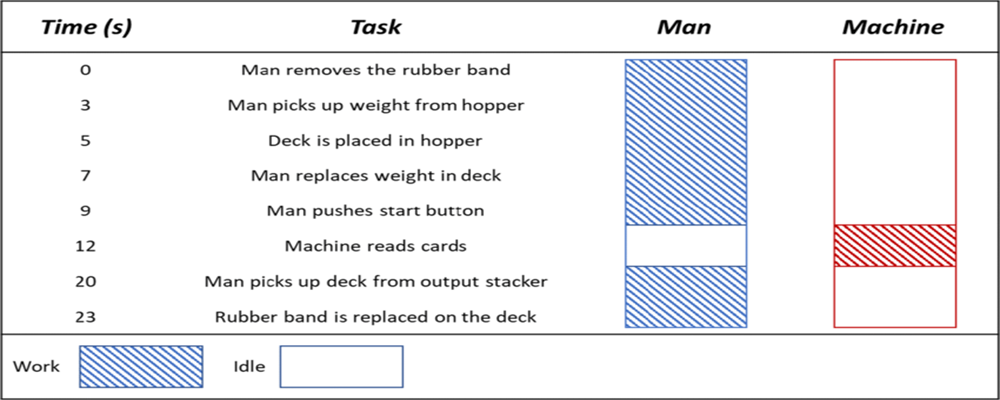

- Preparation of elemental details from the videos recorded for the paint shop, pre-painting and post painting area using PMTS.

- Validation of elemental details from CFT and Work content finalization.

- Bifurcating the time in process time and manual work content.

- Analysis (Work distribution/VA-NVA identification/Line Balancing) for manpower calculation & optimum manpower utilization.

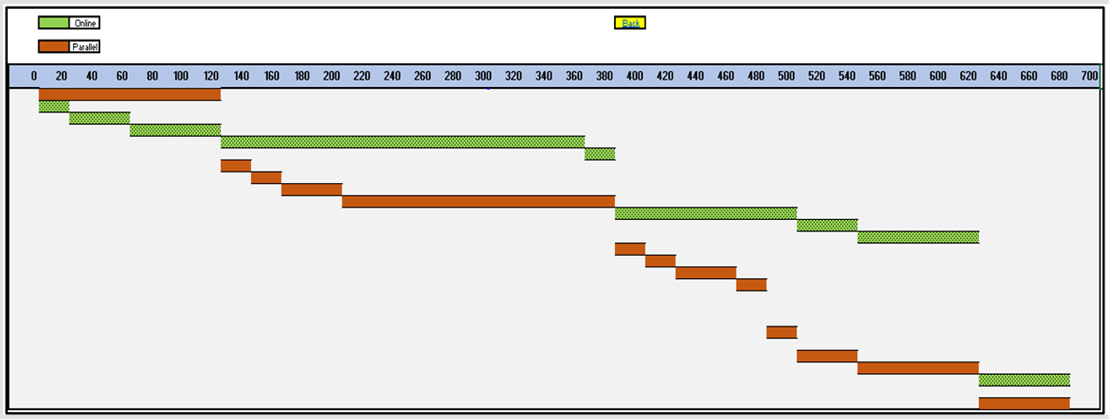

- Excel simulation and stage balancing for overview of data analysed.

Excel Simulation for Pre-Painting:

Findings & Recommendations

After doing analysis and evaluation following results were obtained –

- In existing condition, 1/day is possible after eliminating rework & considering two shift working

- 1/day, 2/day, 3/day on two shift basis can be possible pertaining to modification in paint booth area.

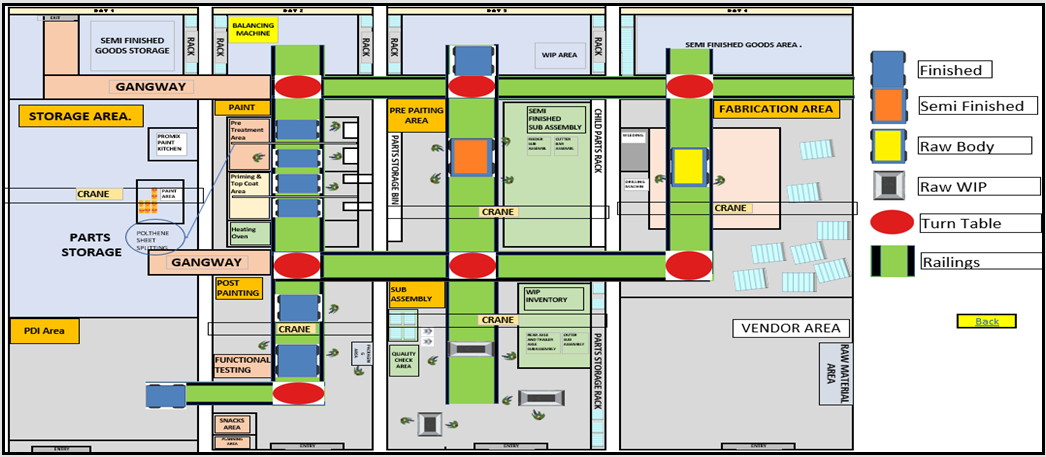

- Proposed Layout for 1/day, 2/day and 3/day.

- Manpower and its utilization.

- Tentative capex sheet for plant modification.

Proposed Sample Layout:

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?

Recent posts