Transform Your Facility for Peak Performance.

Layout is one of the key aspect/parameter of any manufacturing set up, particularly when it comes to productivity, space utilization, product and material movement. Effective theme of layout varies based on nature of manufacturing process. Design of layout depends on many parameters such as availability of space, material movement, material handling movement, cycle time, production level, inventory level, model mix, etc.

Design of layout influences even on the effective supervisory control. A proper layout must respond to fluctuations in demand, model mix variations, new product introduction etc.

PMI offers layout and material flow consulting services to get businesses operating at optimal efficiency.

Our Layout and Material Flow Services Include

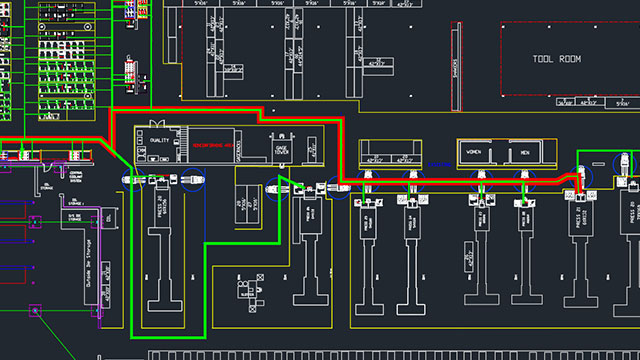

Factory Layout Design & Optimization Services

- PMI designs effective plant/shop/workstation layouts that maximize floor area utilization, with streamlined workflow and minimal congestion.

- We design layouts according to your unique industry requirements, for new facilities or the redesign of existing plants.

- We offer strategic recommendations with the latest analysis and simulation tools to maximize operations and eliminate waste.

Lean Concept MUDA Reduction

- We identify and remove non-value-adding activities (MUDA) to streamline your operations.

- Our lean strategy maximizes processes, minimizing delays and inefficiencies for better output.

- By eliminating waste, we assist in reducing operational costs and increasing cost savings.

- We tailor MUDA reduction strategies to fit your unique production processes and business goals.

Supply Chain Optimization

- PMI assists in analyzing and streamlining your processes for hassle-free and efficient material flow.

- Our professionals look for inefficiencies to remove waste and reduce unnecessary costs.

- We enhance transportation, warehousing, and inventory levels to perform better.

- Our tailored strategies improve responsiveness, reduce lead times, and drive business success.

PFEP Manufacturing Consulting

- Plan For Every Part (PFEP) by PMI structures inventory, supplier information, and production data to improve tracking and planning.

- It provides the right parts at the right time, minimizing excess inventory and avoiding shortages.

- Our support can improve visibility into part movement, packaging requirements, and supplier performance for improved decision-making.

- Our strategies reduce lead times, eliminate bottlenecks, and create a more efficient production workflow.

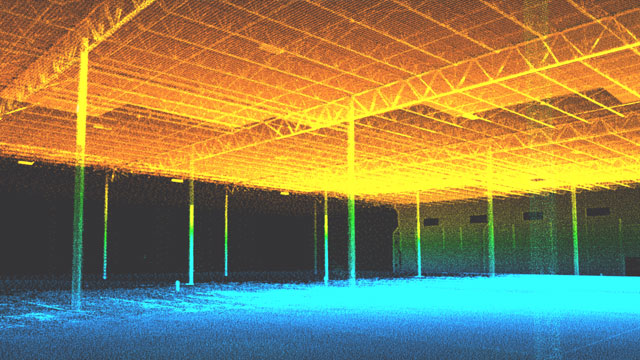

Warehouse Layout Design Services

- PMI designs layouts that maximize storage capacity and improve warehouse organization.

- We improve movement efficiency for you to reduce handling time and streamline operations.

- We also create logical workflows that minimize delays and boost overall warehouse performance.

- Our methods support utilization of wasted space productively and eliminate inefficiencies to reduce operational expenses and increase profitability.

Warehouse Operations Support

- PMI improves warehouse processes and ensures smooth and efficient movement of goods.

- We identify inefficiencies to lower operational expenses and maximize resource utilization.

- Our strategies improve storage, organization, and tracking for better stock management.

- We enhance receiving, storage, and shipping processes to improve customer satisfaction.

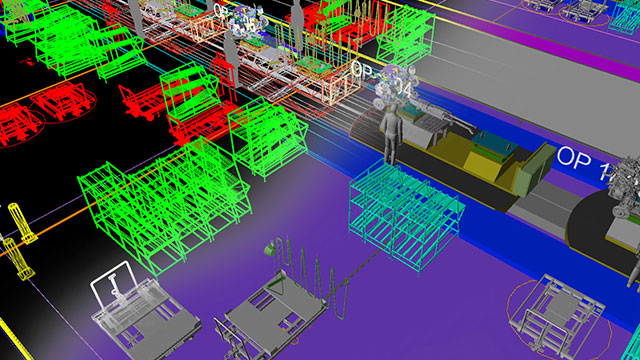

Material Flow Simulation Services

- PMI analyzes material flow in warehouses or factories to enhance efficiency and streamline daily operations.

- Our simulations detect inefficiencies in material handling, helping businesses eliminate delays and improve workflow.

- We use modeling methods to forecast results, enabling firms in pilot solutions before expensive changes.

- By streamlining procedures, we help companies to reduce downtime, improve workflow and increase overall productivity.

Material Handling Consulting Services

- PMI analyzes and refines material handling processes to enhance efficiency, reduce costs, and improve workflow.

- Our experts design tailored strategies to address specific material movement challenges within your facility.

- We ensure material handling systems meet industry safety standards while minimizing risks and operational hazards.

- By streamlining material flow, we help businesses achieve faster throughput and higher overall operational efficiency.

Ergonomics Assessment + Material Handling

- We evaluate material handling tasks to identify ergonomic hazards which may result in straining or injury.

- Our suggestions enhance workstation design, tool usage, and work processes for more efficient and safe operations.

- By curing poor posture, repetitive motion, and overuse physical stress, we help to reduce workplace injury.

- Ergonomic design improvements yield greater comfort, reduced fatigue, and overall increased effectiveness in material handling tasks.

Industries that Benefit from Layout and Material Flow Services

Automotive Manufacturing

Logistics & Supply Chain

Telecommunications

Warehouse & Logistics

Aerospace

Architecture

Industrial Manufacturing

Energy and Utilities

Engineering

Food and Beverage

Renewables, Oil, and Gas

Construction

Healthcare and Hospitals

Retail

Our Layout and Material Flow Expert

PMI’s team of experts delivers comprehensive Lean Manufacturing Consulting services with decades of experience in material flow and layout design. Our wide-ranging expertise allows us to effectively serve various markets. Our experts offer tailored solutions based on your specific requirements and industry type, resulting in optimized production processes and detailed improvement reports.

- Carefully select the most appropriate techniques based on your specific scenario and objectives

- Applying the best methods for your specific industry type

- Providing detailed optimization recommendations and reports to help improve your processes

Advantages

Advantages and Benefits of Layout and Material Flow Services

At PMI, layout and material flow planning are given the importance it deserves. With simplicity at the center of our approach, we function through the principles of:

- Improved visibility for supervisors

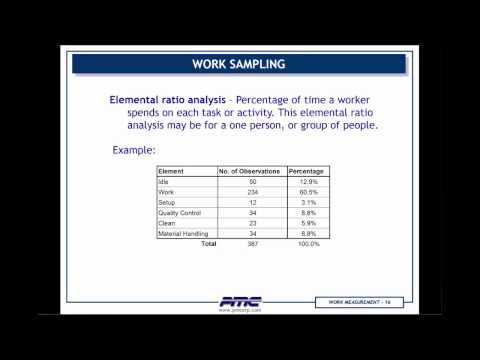

- Time study facilitates identification of bottleneck in overall system

- Inventory optimization and control

- Identifying the least possible wastage

- Better utilization of resources and assets

- Lower production costs

Training on Industrial Engineering Concepts/Techniques and Methodology

PMI offers a variety of Industrial Engineering training courses. From Six Sigma, Lean Manufacturing Techniques, 8S Core Courses, and beyond, PMI can help you enhance your organization’s manufacturing capabilities and drive operational excellence with our comprehensive courses.

These courses offer you specialized knowledge and experience in industrial engineering with best practices and the latest techniques in the field

- Expertise Specialized knowledge and experience in industrial engineering provide your employees with the latest techniques and best practices in the field.

- Tailored Solutions Conduct an analysis of your organization's operations and provide tailored training solutions. This can help your organization to achieve its unique goals and objectives.

- Implementation Support Training alone is not enough! We can provide support in implementation which will ensure that learned techniques drive effective changes.

- Long-term Benefits Implementing industrial engineering solutions can lead to improvements in productivity, efficiency, and profitability.

Frequently Asked Questions

Layout & Material Flow Services involve analyzing and optimizing the physical arrangement of equipment, workstations, and storage areas within a facility to ensure efficient movement of materials and personnel. The goal is to enhance productivity, reduce waste, and improve overall operational efficiency.

An optimized facility layout and material flow can lead to:

• Reduced material handling costs.

• Improved throughput and productivity.

• Minimized space requirements.

• Enhanced safety and ergonomics.

• Better inventory control and reduced lead times.

By streamlining processes and eliminating inefficiencies, businesses can achieve significant cost savings and operational improvements.

PMI provides a comprehensive suite of services, including:

• Factory Layout Design & Optimization.

• Lean Concept MUDA Reduction.

• Supply Chain Optimization.

• Plan for Every Part (PFEP) Manufacturing Consulting.

• Warehouse Layout Design Services.

• Warehouse Operations Support.

• Material Flow Simulation Services.

• Material Handling Consulting Services.

• Ergonomics Assessment & Material Handling.

These services aim to enhance operational efficiency and productivity across various industries.

Material Flow Simulation uses modeling techniques to visualize and analyze the movement of materials within a facility. This helps in:

• Identifying bottlenecks and inefficiencies.

• Evaluating potential layout changes before implementation.

• Predicting the impact of process modifications.

• Making informed decisions to improve material handling and overall performance.

PFEP is a structured approach to managing information related to every part in a manufacturing system. It involves tracking data such as inventory levels, supplier details, production processes, and packaging requirements. Implementing PFEP helps in:

• Streamlining the supply chain.

• Improving inventory accuracy.

• Enhancing production efficiency.

• Reducing operational costs.

Ergonomics assessments evaluate how work tasks, equipment, and the environment affect worker safety and comfort. In material handling, this leads to:

• Reduced risk of injuries.

• Improved employee well-being.

• Enhanced productivity.

• Optimized workstation design for efficiency.

Revisions should be considered when:

• Dealing with legacy structures or business acquisitions.

• Restructuring or reorganizing existing facilities.

• Constructing new facilities.

• Experiencing significant changes in manufacturing volume.

Timely revisions ensure that the facility adapts to evolving operational needs and maintains optimal efficiency.

Industries that can benefit include:

• Automotive Manufacturing.

• Warehouse and Logistics.

• Industrial Manufacturing.

• Food and Beverage.

• Healthcare and Hospitals.

• Aerospace.

• Energy and Utilities.

• Retail.

• Telecommunications.

• Architecture, Engineering, and Construction.

These services are versatile and can be tailored to meet the specific needs of various sectors.

MUDA refers to non-value-adding activities or waste in processes. Integrating Lean Concept MUDA Reduction with layout optimization helps in:

• Identifying and eliminating wasteful practices.

• Streamlining workflows.

• Enhancing process efficiency.

• Reducing operational costs.

This integration ensures that the facility layout supports lean operations and continuous improvement.

To get started:

• Visit the Layout & Material Flow Services page.

• Fill out the contact form to describe your project or request a quote.

• Schedule a consultation with PMI's experts to discuss your specific needs and objectives.

PMI's team will guide you through the process, from initial assessment to implementation, ensuring tailored solutions for your facility.

Want to schedule a time to speak with one of our Material Flow & Layout Design Consulting representatives now?

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!