Enhance Decision-Making, Model System Scenarios, and Minimize Implementation Risk.

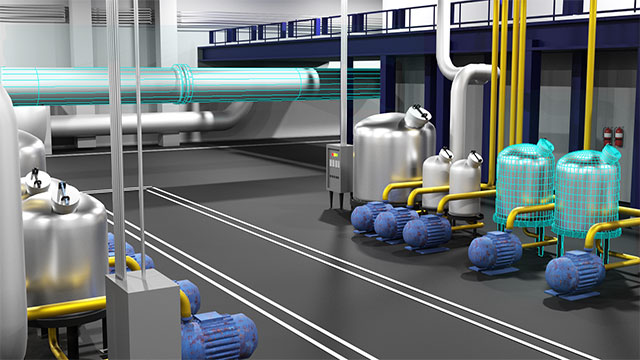

PMI provides Simulation Services to a variety of clients from warehouses to manufacturing and automotive plants. A simulation model is a 2D or 3D model of a system that allows potential issues and bottlenecks to be identified and managed more efficiently. The ability to test processes and play out “what-if” scenarios prior to implementation mitigates the potential for extremely costly mistakes and amplifies your ability to make informed decisions.

Simulation simplifies the assessment of spaces on metrics such as performance, processing speed, capacity, staffing needs, and other planning factors. Additionally, it offers visual representation capabilities, enabling evaluation and comparison of different space scenarios.

Industrial Engineering Simulation Applications & Benefits

Reduce labor and equipment costs with virtual environments by maximizing storage, product movement, and process flow.

Adapt to operational needs and forecast future requirements by planning and optimizing warehouse layouts and operations with simulation modeling.

- Ergonomics

- Analyze ergonomic employee data

- Gain insight on where improvements in workspaces can be made

- Use “what-if” scenarios to calculate the best ergonomic improvements

- Material Flow and Material Handling Simulation

- Explore ‘what-if’ process flow scenarios

- Visualize long term effects on equipment and mitigate maintenance

- Identify bottlenecks in material, information, and product flows

- Robotics Simulation

- Use ‘what-if’ scenarios to account for human placement and avoid collisions

- Predictive maintenance

- Improve layouts, logistics, and material placement

- Automated Guided Vehicles (AGV) Simulation

- Gather information that allows for predictive maintenance considerations

- Plan AGV routing for logistics optimization

- Improve safe operation in human workspaces

- Conveyor Simulation Consulting

- Experiment in a virtual environment first without having to experiment on the system itself

- Analyze control logic, merge logic, and robot interactions

- Layout Optimization Consulting

- Use in pre-planning or work with existing conditions

- Use virtual scenarios to optimize inventory and process flow

- Resource Optimization Consulting

- Map out the best use of your resources and material

- Production line balancing, inventory planning, and staff allocation

- Warehouse Simulation

- Plot and visualize warehouse traffic routes to avoid areas of congestion and collisions

- Plan out storage, docks, AGVs, and product placement

- Throughput Analysis

- Analyze material flow and resource utilization

- Bottleneck detection and machine operation capacities

- Account for supply chain and business processes

Software & Technologies

Siemens Tecnomatix

PlantSim

Siemens Tecnomatix

Process Designer

Siemens Tecnomatix

Process Simulate

Siemens Tecnomatix

Human

Our Experts

With over 30 years of experience with modeling technology, software, and 3D models, PMI brings knowledge and experience to your project. We employ highly experienced team members and industrial engineers who possess a wealth of knowledge in multiple industries. Let our qualified experts help meet your needs.

Industries that Benefit from Simulation Modeling Services

Automotive Manufacturing

Warehouse and Logistics

Industrial Manufacturing

Food and Beverage

Healthcare and Hospitals

Logistics & Supply Chain

Aerospace

Energy and Utilities

Renewables, Oil, and Gas

Retail

Telecommunications

Architecture

Engineering

Construction

Simulation Modeling Training

Our team provides standardized and customized simulation training across all markets. Not only do we train in best practices, but we provide in-depth training on the software itself.

PMI Simulation Trainings offered both online and in-person:

- Arena Simulation Workshops

- Tecnomatix Plant simulation workshop

- ProModel Simulation Workshops

- Simul8 Workshops

- WITNESS Simulation Workshops

- AutoMod Simulation Workshops

- Enterprise Dynamics Simulation Workshops

- Simulation Input Data and Output Results Analysis

We also offer Industrial Engineering and Quality Management training courses:

- SixSigma, Statistics, and Data Analysis Workshops (Experiment Design, non-parametric data, multi-verite data, DMAIC / DFSS blackbelt, greenbelt and yellowbelt)

- VDA 6.3 Quality Management

- Automotive Quality Core Tools

- Automotive Quality Management

- Electrostatic Discharge Management

- Environmental Management Systems

- Layered Process Audit

- Lean Healthcare Workshops

- Lean Manufacturing Workshops

- Lean Office Administration Workshops

- Occupational Health and Safety

- Productivity Improvement in Operations Workshops

- Quality Management Systems

Simulation Modeling Media

Speak with one of our Industrial Engineering Experts!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our Industrial Engineering representatives NOW?