Work Content Measurement and Process Improvement in a BOPP Film Manufacturing Plant Using PMTS Techniques

The client is a prominent manufacturer and supplier of specialized packaging and ultrahigh barrier solutions, excels in sustainable products for global markets. Renowned for BOPP films across diverse sectors, they champion sustainability for brands and converters. Through PMTS techniques, they optimize work content, manpower, and process improvements, with a focus on material flow and layout design. This case study showcases their commitment to innovation and eco-friendly solutions.

Key Points

- Productivity improvement by 45%.

- Manpower reduction by 31%.

- Increased manpower utilization to 73%.

Client's Challenge

- Reduction in manpower.

- Dashboards for production planning as per demand.

- Material flow and layout.

- Low manpower utilization.

PMI's Approach

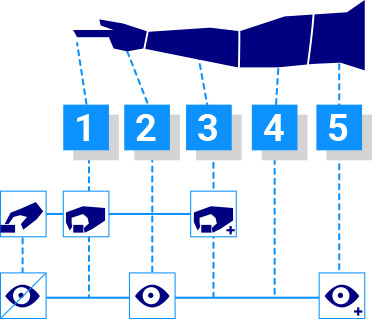

The study was organized in a 3-stage process:

- Data Collection - Video shooting of all activities on the line.

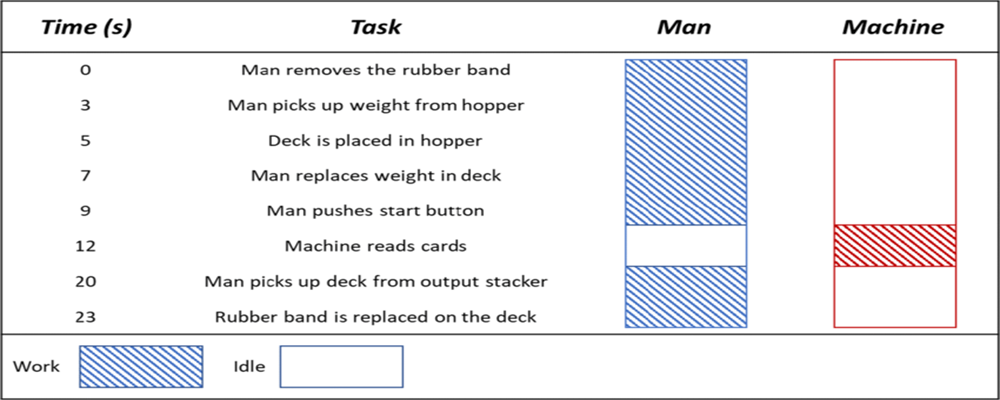

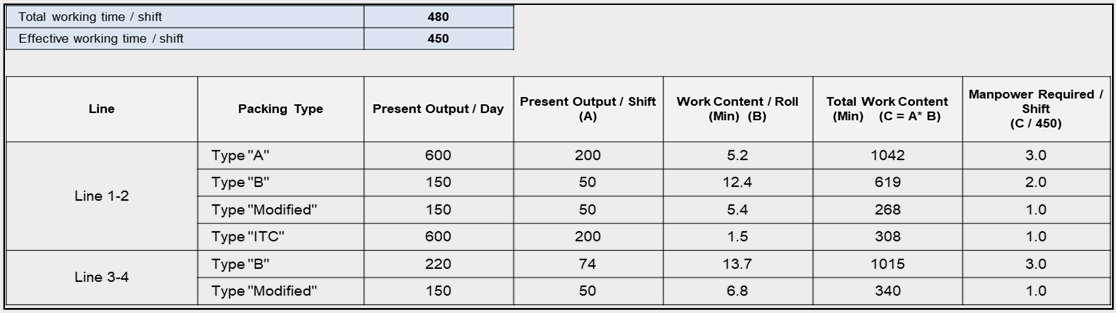

- Estimation & Data Analysis – MODAPTS estimation, work distribution, dashboard preparation, synchronous material flow design and layout modifications.

- Results and Conclusion – Dashboards for future planning, fatigue reduction, improved productivity, improved manpower utilization, identification of NVA work content.

Data Analysis:

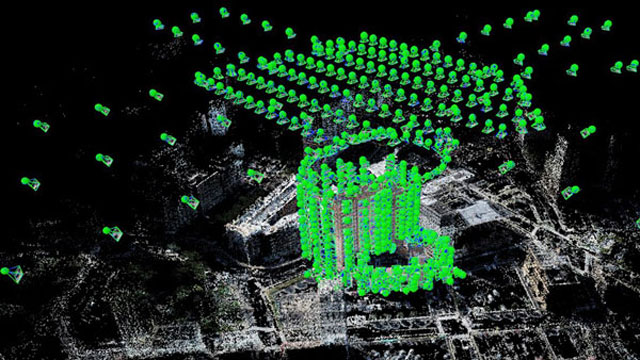

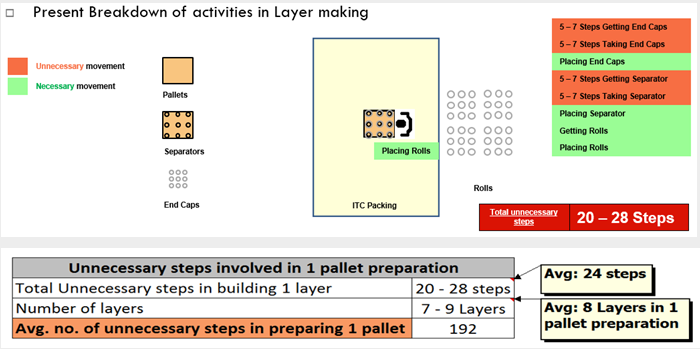

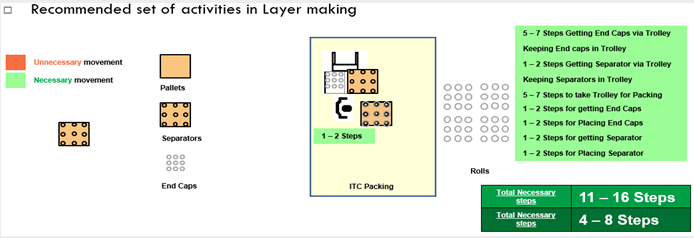

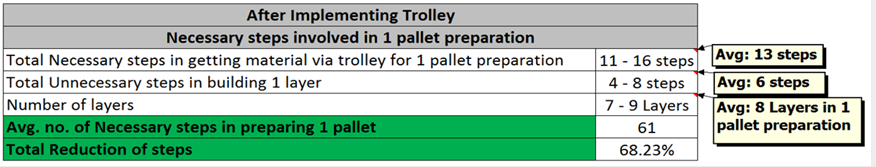

Synchronous Material Flow and Layout Modification

Existing Scenario:

Proposed Scenario:

Results & Conclusion

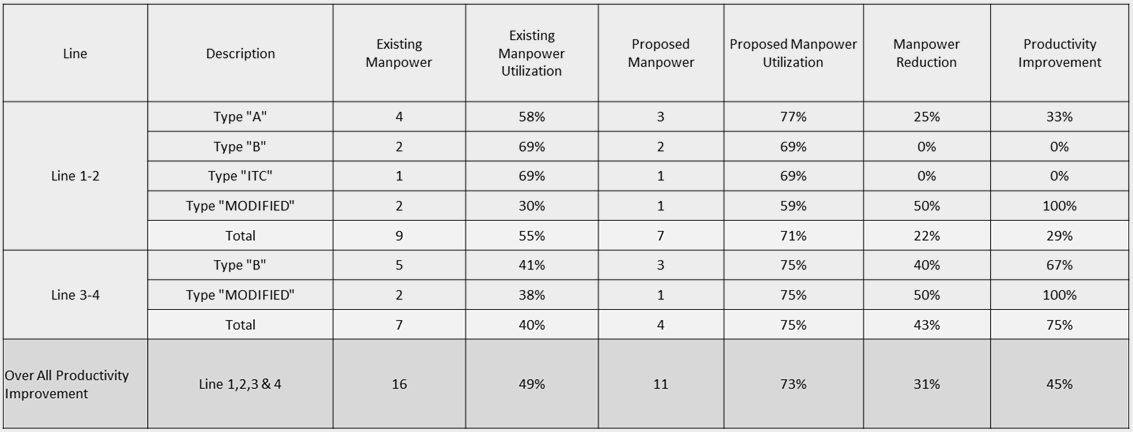

After doing analysis and evaluation following results were obtained –

- Improved productivity by 45%.

- Manpower reduction by 31%.

- Manpower utilization rose from average of 49% to an average of 73%.

- Dashboards for future planning as per demand & as per working lines.

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?

Recent posts