Challenges Encountered

Even with a highly established production line, the client encountered some issues that were capping performance:

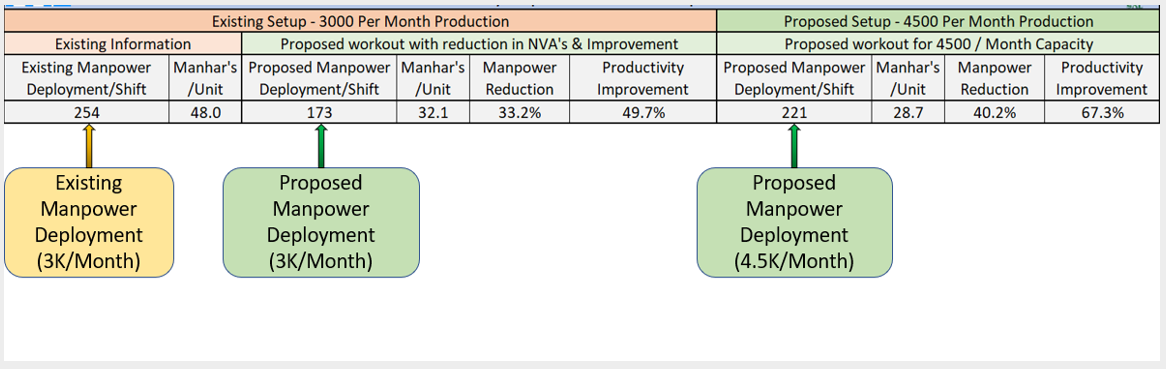

- Poor task allocation and repetition-based workloads that caused high manpower fatigue.

- Inefficient utilization of manpower, with workflows resulting in wasted time.

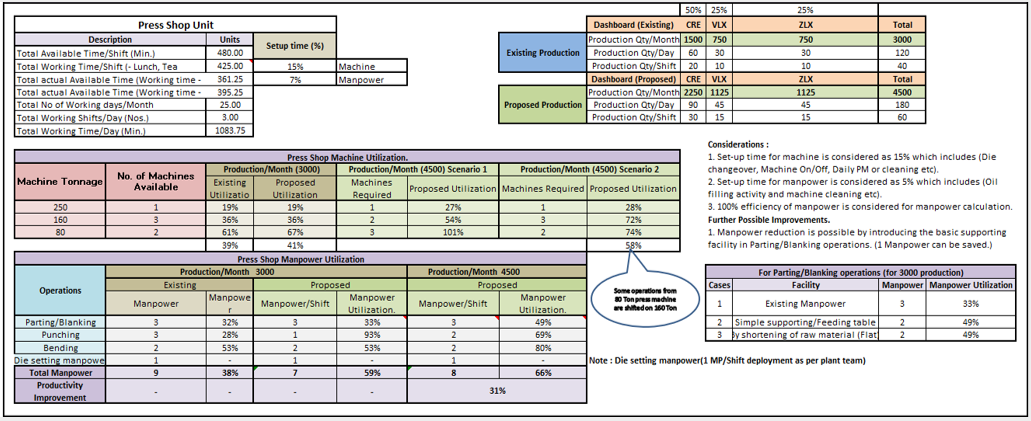

- Inadequate data-driven planning tools, capping visibility into actual production capability.

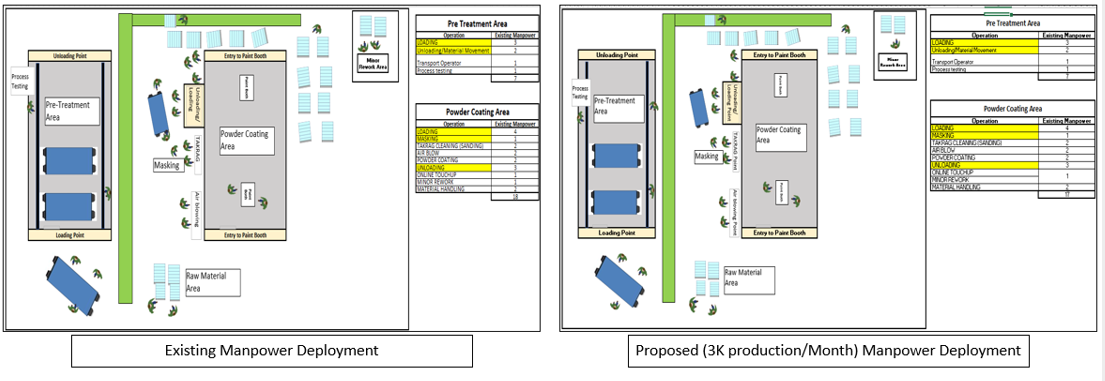

- Suboptimal plant layout, increasing unnecessary motion and travel

- The absence of automation in simple but labor-intensive processes.

These challenges not only impacted productivity but also reduced the factory's ability to scale up to future production targets.