Challenges Encountered

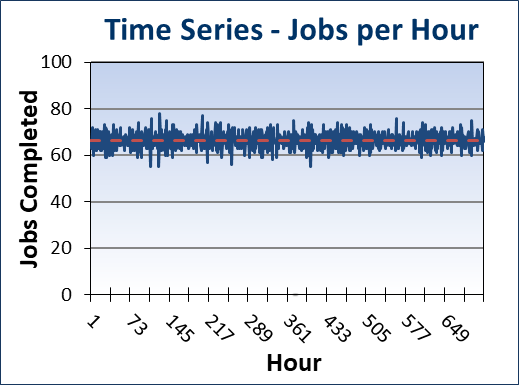

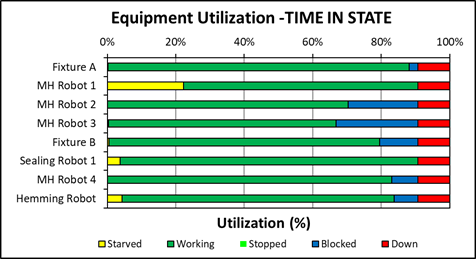

Despite a sophisticated design, hard realities such as variability in robotic cycle time, delay in part flow, and station dependency could not be engineered or simulated adequately using conventional static models. Some of the main challenges were:

- Ensuring the design feasibility for dynamic production situations

- Identifying hidden bottlenecks in the workflow

- Estimating minimum buffer requirements without excessive space utilization

- Resolving issues around robot sequencing and downtime handling

Without solving these challenges, there was a risk of underperforming throughput and frequent line stoppages in actual operations.