Key challenges involved:

The major objectives of the simulation exercise were to:

- Absence of standardized work processes using PMTS techniques

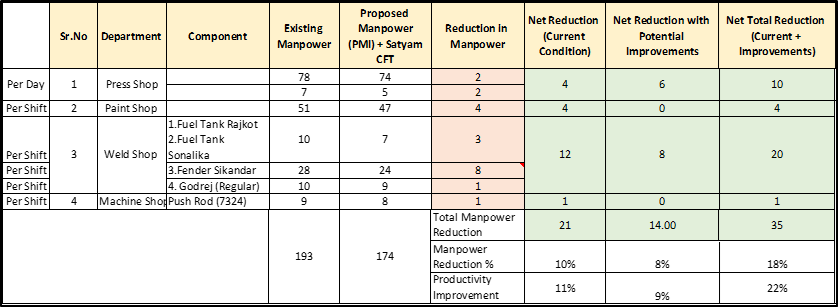

- Inability to accurately measure true plant capacity

- Limited utilization of manpower resources

- Inefficient layout that affected material and workflow

- Lack of dashboards for demand-based production planning

- Unclear visibility into VA/NVA activities, resulting in wasted effort

These challenges severely impacted the operational efficiency for the clients in negative terms which further made it difficult for them to make informed decisions. They were also unable to respond to changing demands and plan for future expansions.