Simulation Study to Validate the EMS Loop & Gantry System for a Tyre Manufacturer

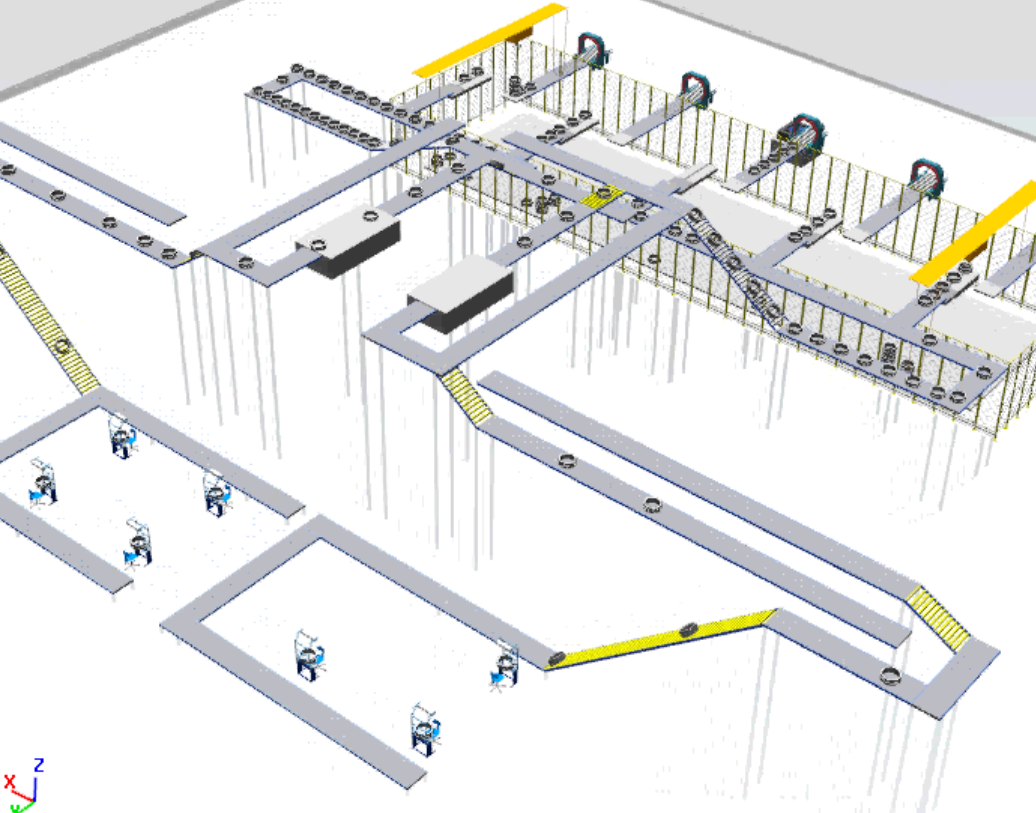

One of India’s leading tyre manufacturers expanded its existing facility to double its production rate. New EMS (Electro Monorail System) loops, ASRS (Automated Storage & Retrieval System) facility, conveyor systems and gantry cranes were set up to streamline flow and automate handling of tyres.

Key Points

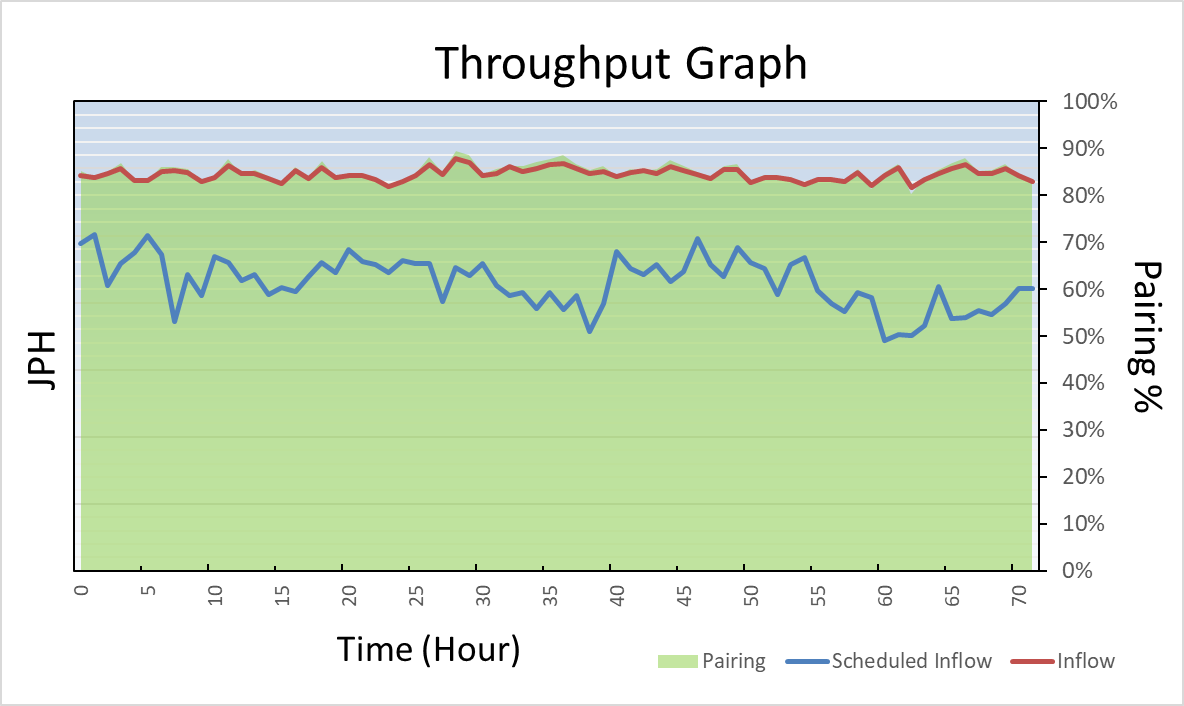

- To validate the new EMS loops, ASRS facility, conveyor systems, Gantry to achieve the required throughput

- Identify the Bottleneck in the system

- Provide recommendations to alleviate the same

Client's Challenge

- Identify capacity of existing system

- Find out reasons for production loss

- Investigate excessive inventory build-up

- Define optimal strategies for efficient operation

PMI's Approach

We carried out static analysis, 2D and 3D simulation to study in detail:

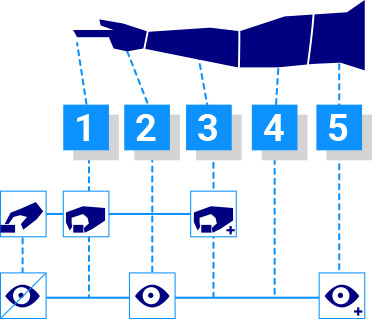

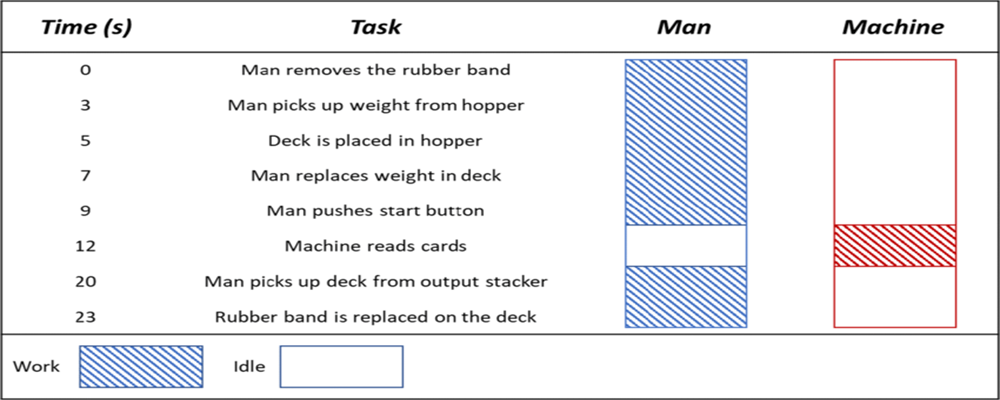

- EMS Loop with loading and unloading stations along with operating logics

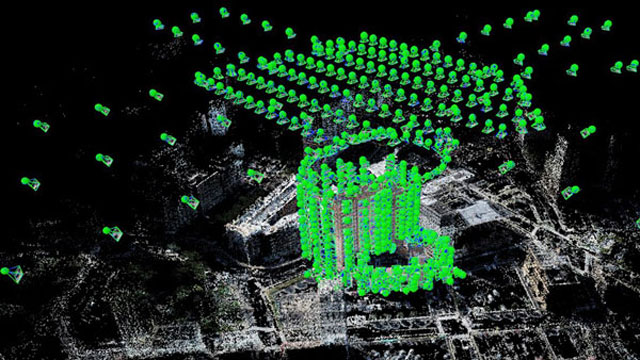

- ASRS, inlet and exit stations with 7000 tyre capacity

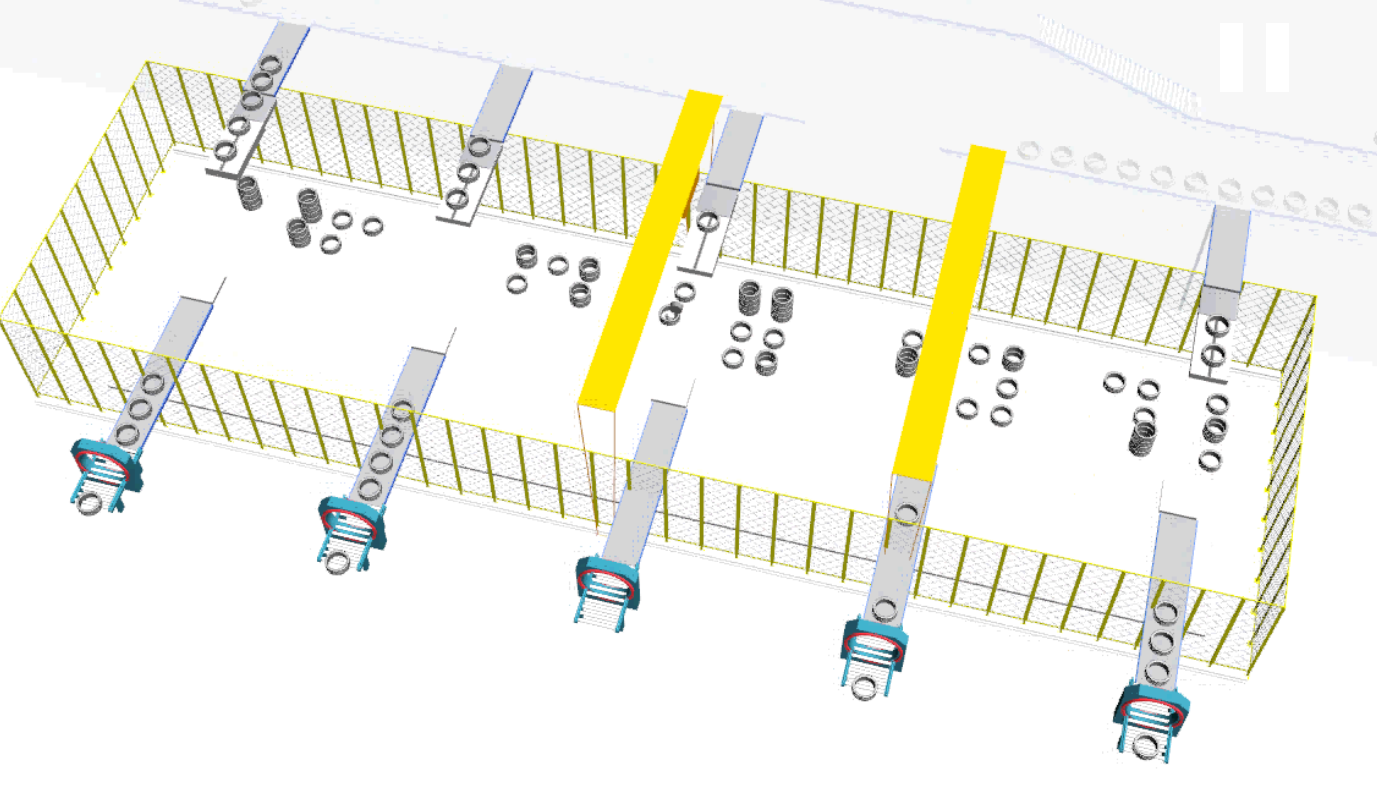

- Gantry system of 1500 sq. meters area and 6000 tyre capacity

Finding & Recommendations

Unloading stations of EMS Loop was the bottleneck

- Using additional station improved the performance

Operating pattern of EMS carriers was blocking the tyre supply from building machines

- Using 2 tyres per EMS carrier improved the capacity by 25% and halved the carrier requirement

ASRS handling partial loads due to unavailability of two back-to-back tyres of same type

- Ensuring that no order is left unattended at unloading station ensured the partial loads can be processed without affecting ASRS performance

Inspection station and conveyor flaps led to mixing of tyres causing gantry to wait for back-to-back tyres of same type

- Optimized working of conveyor flaps and proposed new buffer near inspection to send out similar tyres together

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?

One of India’s leading tyre manufacturers expanded its existing facility to double its production rate. New EMS (Electro Monorail System) loops, ASRS (Automated Storage & Retrieval System) facility, conveyor systems and gantry cranes were set up to streamline flow and automate handling of tyres.

Recent posts