3. Results & Conclusion

Embedding real-time data within VSMs had a dramatic impact on visibility and responsiveness:

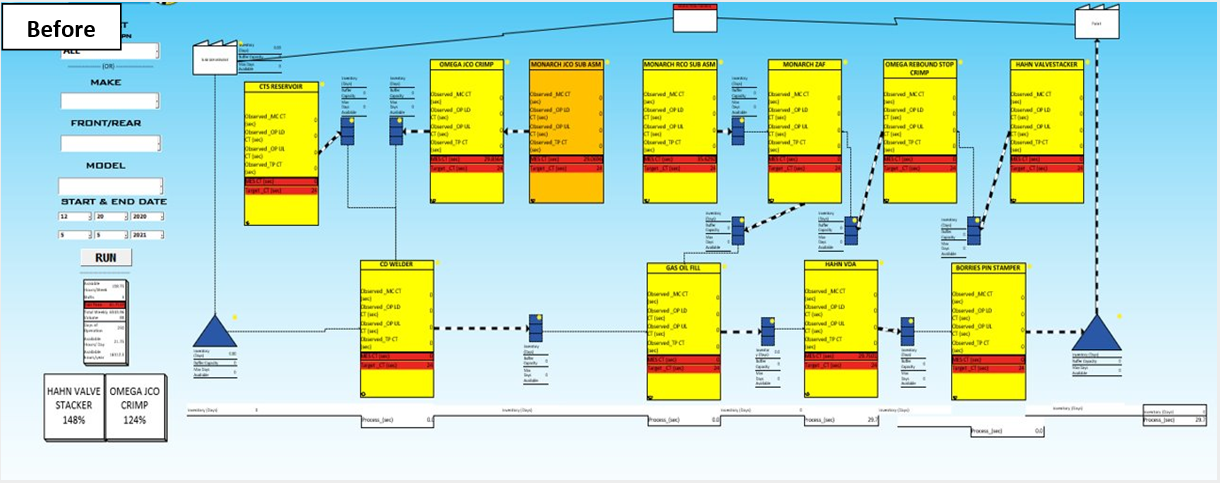

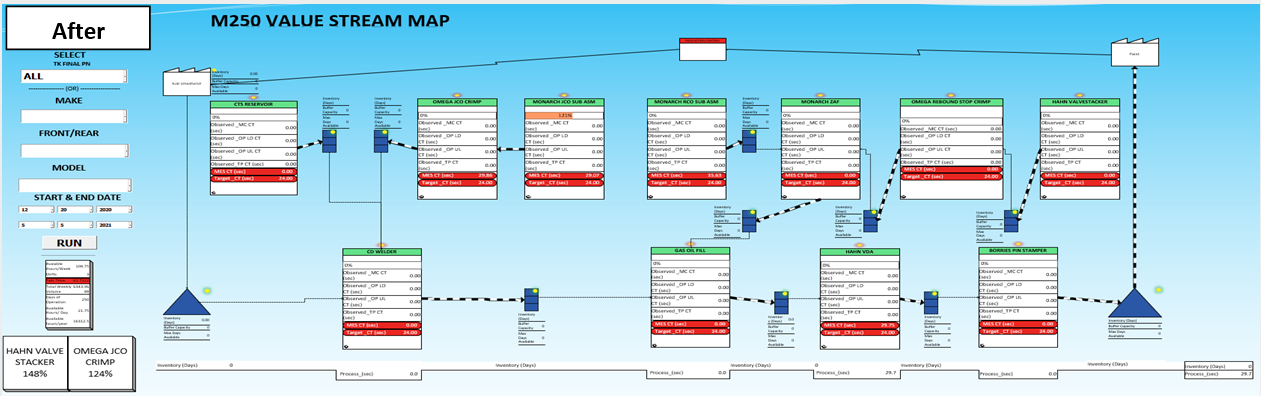

• Improved VSM Usability: Through updated symbols and dynamic dashboards, the VSMs were no longer static diagrams but dynamic management tools.

• Real-Time Process Mapping: Production flow, inventory, and lead times were instantly visible, making it easier to respond to issues quickly.

• WIP Optimization: In-flight monitoring allowed for proactive WIP level management, avoiding bottlenecks and lowering idle inventory.

• Better Decision-Making: Supervisors and planners could now trust VSM dashboards for better planning and shift allocation.

• Foundation for Continuous Improvement: The system created a basis for continued Lean efforts, facilitating kaizen activities and process reengineering.

By correlating 13 product lines with actual time production data, the customer not only achieved more control over manufacturing operations but also established a foundation for more intelligent, more rapid, and more agile production systems.