Objectives of the Study

Having realized the necessity for data-driven process improvement, the client engaged Production Modeling India (PMI) to carry out a targeted study with the following major objectives:

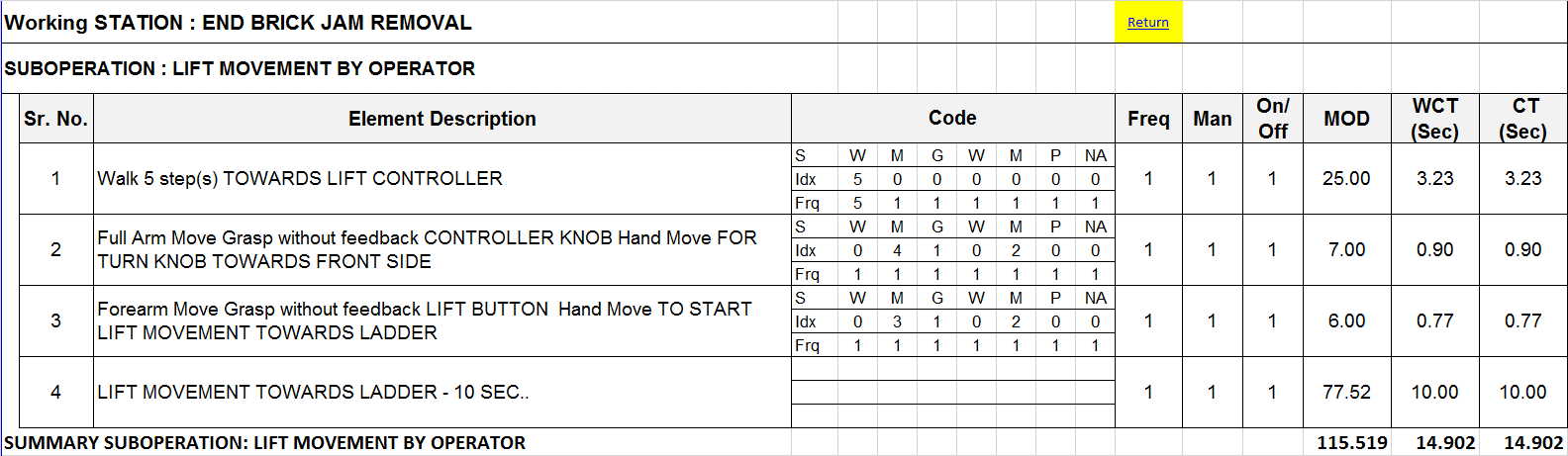

- Accurate measurement of setup activity work content through the PMTS technique.

- Measurement and identification of losses during setup activities.

- Benchmarking of actual setup time versus ideal standards.

- Development of suggestions to reduce fatigue and process improvement.

These targets were defined with the aim of demonstrating quantifiable increases in setup efficiency, thus driving improved equipment use, reduced downtime between production runs, and overall excellence.