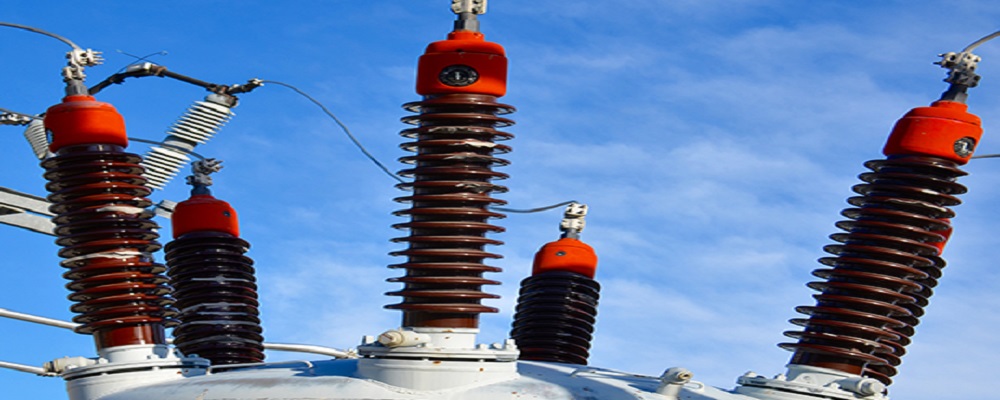

Automotive Power and Free System

AUTOMOTIVE INDUSTRY Power & Free Conveyor system

Congestion Analysis: Closed Loop Material Handling System

Key Points

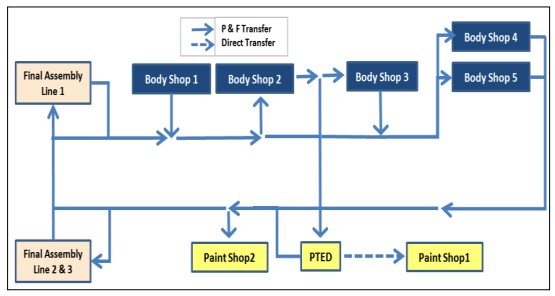

- Closed loop power & free(P&F) system

- This P&F system transports:

1. Empty Hangers

2. BIW

3. CED Bodies

4. Painted Bodies - Different production levels across five body shops

- Staggered placement of body shops complicates the

empty hanger distribution

Client's Challenge

- Whether P&F conveyor is capable to meet required production volumes

- If not, actions required to meet the target

- Finished BIW Buffer requirements

PMI's Approach

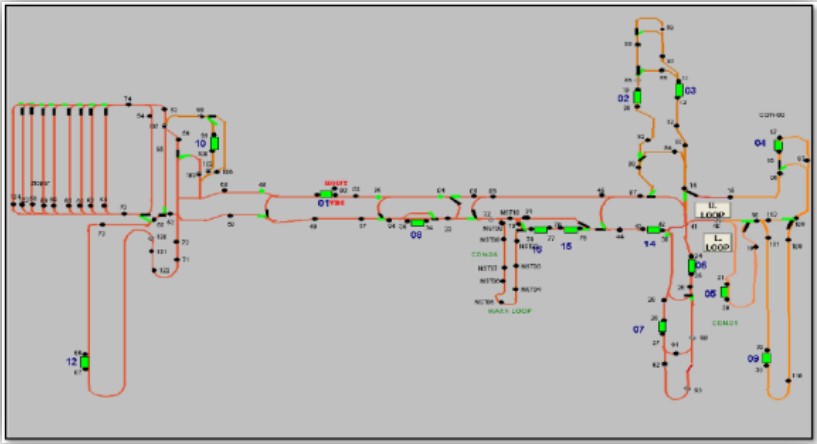

- Data analysis, 2D model building, verification & validation

- Bottleneck Identification

- "What If" experimentation to achieve set target

1. Impact of Change in no. of Hangers

2. Distribution of hangers on various junction points

3. Buffer analysis

Findings & Recommendation

- Facility was unable to meet target production volume

- Distribution of hangers at various junctions played key role

- Production volume also dependent on number of hangers

- Reduce the number of empty hangers to meet the target

- Distribution of empty hangers at various junction points

- Number of empty hangers to be parked in different places

- BIW Buffer size was estimated

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?