Elevating Operational Excellence in Electrical Insulator Manufacturing Industry

This case study presents a deep exploration of a distinguished manufacturer and supplier specializing in a wide array of critical products, including cable connection systems, asset protection solutions, cable management innovations, electrical safety offerings, heat tracing systems, and more. Rooted in the vision to deliver cutting-edge products and solutions for energy infrastructure, the company embarked on a transformative journey to optimize its operations across various fronts. The study serves as a blueprint for manufacturers seeking to optimize their operations in the realm of energy infrastructure products. Through a strategic amalgamation of PMTS techniques, resource calculations, automation, and systematic NVA elimination, the company successfully elevated its operational excellence and realized its vision of providing top-tier solutions to the energy infrastructure sector.

Key Points

- Work content measurement using PMTS techniques.

- Work Distribution/Line Balancing for manpower utilization.

- Resource calculations i.e., manpower as well as machines.

- Improvement & suggestions for making existing system better.

Client's Challenge

- Balancing of resources (Man and Machine) in three lines.

- Improvement in manpower utilization.

- Identify maximum capacity of stations and machine utilization.

- Eliminates NVA from all areas.

PMI's Approach

- Video shooting of all activities that are in scope of work.

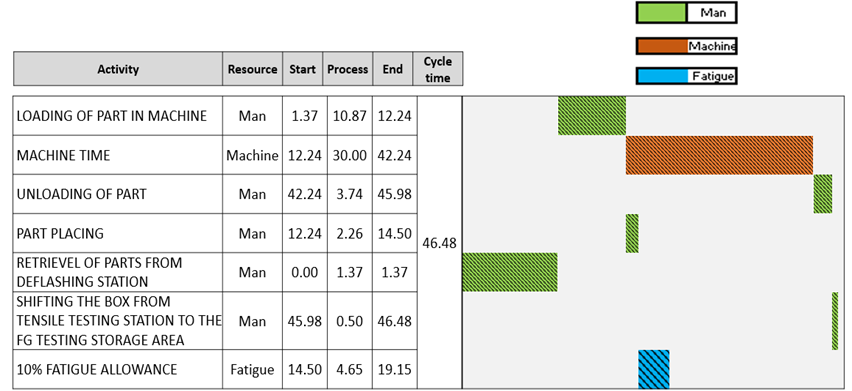

- Work content determination for all activities using MODAPTS technique of PMTS.

- Work content finalization.

- Manpower utilization calculation and balancing of activities for increase manpower utilization.

Data Collection:

- On-site visit - Visiting Facility by PMI team for data collection.

- Understanding Process - Understanding processes & data collection from client.

- Video Shooting - Video shooting & observation of machine as well as manual activities.

- Video Sharing - Sharing of videos with client

Data Analysis:

- Client CFT team supported during data collection phase for better understanding of process flow.

- Elemental details validation & all areas analysis discussed with client and finalized it. Some improvement points are given to client to increase plant productivity.

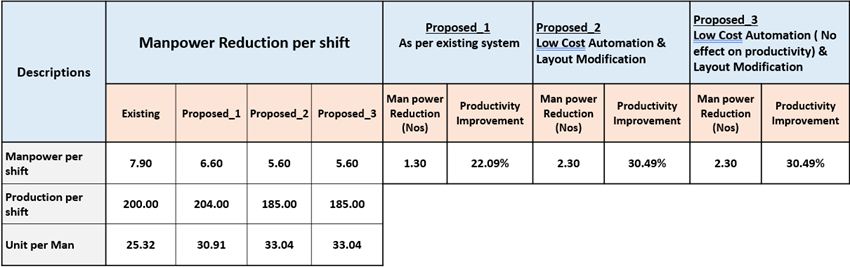

Results & Conclusion

We have proposed three conditions to client to get manpower saving on different conditions. Which are mentioned in below

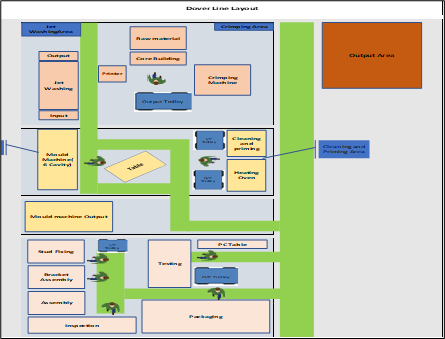

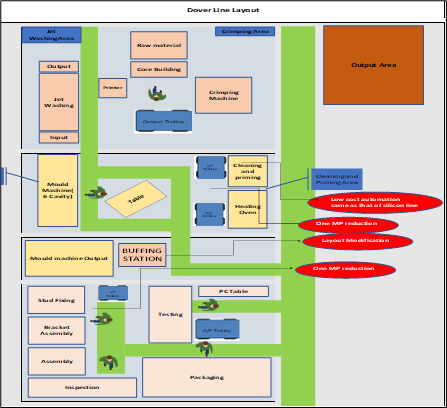

Existing Layout

Proposed Layout

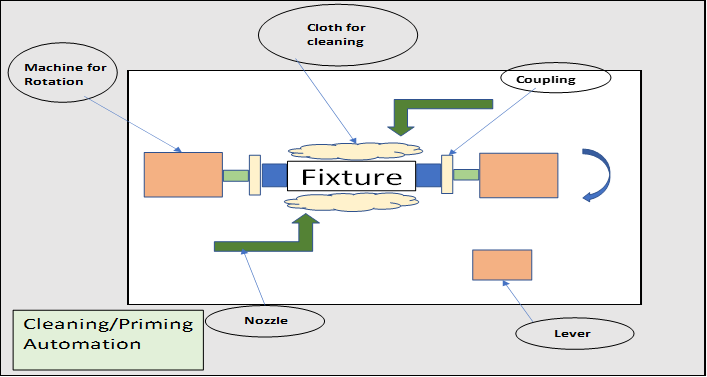

Low Cost Automation-Dover Line:

Low Cost Automation-Dover Line

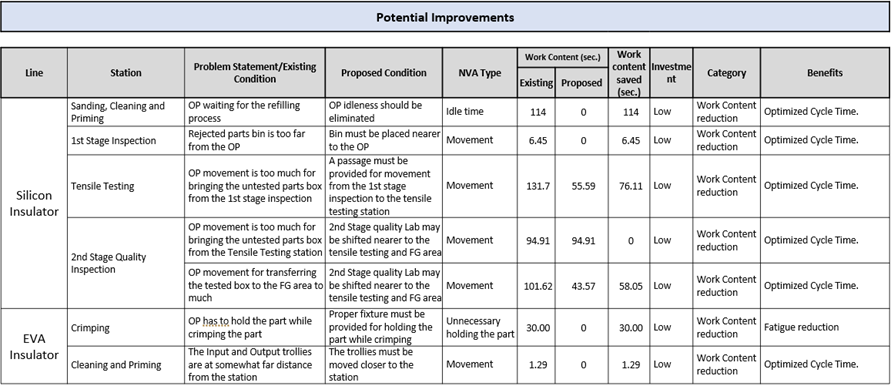

Potential Improvements

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?