Transforming Electrical Soft Ferrite Core Manufacturing Industry through IE Study

This case study spotlights a major player in India's soft ferrite sector, aspiring to pioneer inventive electrical core designs. The study encompassed diverse areas – Press, Sintering, Grinding, Tumbling, Coating, and Packing – aiming for efficiency and excellence. Techniques like PMTS gauged work content, enabling insightful manpower distribution. Dashboards for dynamic production planning, coupled with resource calculations, underscored strategic resource allocation. Improvement insights further enhanced the client's drive toward innovation and operational finesse.

Key Points

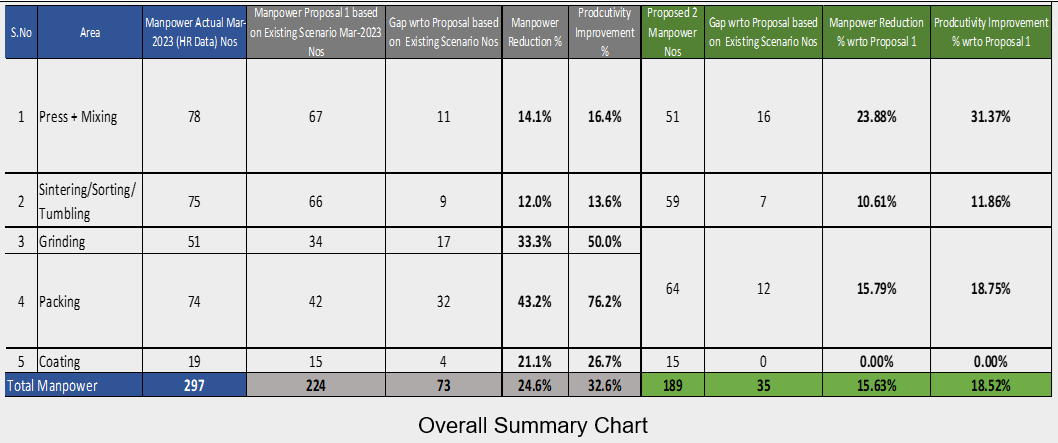

For Existing Condition

- Productivity improvement by 35.22%.

- Manpower reduction by 26.94%.

For Proposed Condition based on Multi-manning and Layout Modifications

- Productivity improvement by 59.49%.

- Manpower reduction by 38.55%.

Client's Challenge

- Work standardisation across various variety of cores produced.

- Reduction in manpower fatigue.

- Dashboards for production planning as per demand for both daily and monthly production.

- Low manpower utilization.

- Layout Modification

- Low-Cost Automation wherever applicable

PMI's Approach

The study was organized in a 3-stage process:

- Data Collection - Video shooting of all activities on the line.

- Estimation & Data Analysis – MODAPTS estimation, work distribution, Area wise dashboard preparation, Area wise Monthly Production Dashboard.

- Results and Conclusion – Dashboards for future planning, fatigue reduction, improved productivity, improved manpower utilization, identification of NVA work content.

Involvement of Associates –

- PMI – 1 Project Manager, 2 Engineers.

- Client – 2 Project Co-ordinators.

Data Collection:

- Recording videos by PMI Engineers.

- Interaction with client to understand process.

- Production Data for 2-3 month.

- Data requirement posted for all the kinds of cores produced and process carried out based on different variety of cores.

Data Analysis:

- Preparation of elemental details using PMTS technique & validation by client.

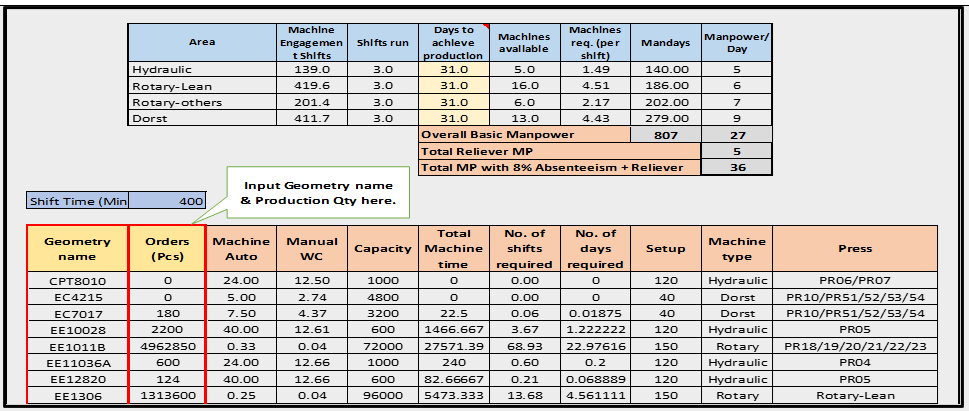

- Analysis (Work distribution/VA-NVA identification) for manpower calculation, optimum manpower utilization & identifying capacity.

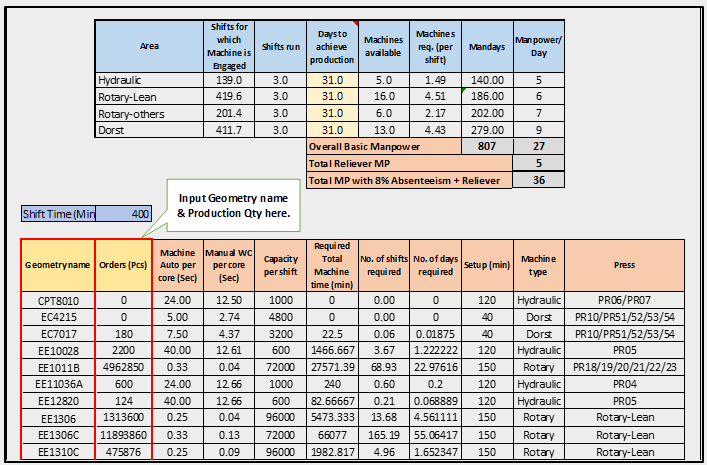

- Dashboard preparation for Area wise production planning as per demand.

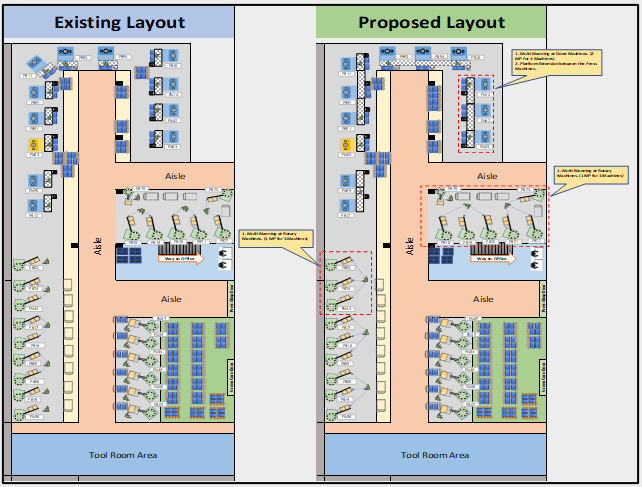

- Layout Modification to improve the process/eliminate NVA movement.

- Improvement & suggestions for fatigue reduction & making existing system better.

Monthly Dashboard based on Production

Area-wise Dashboards

Layout Modification/Multi-manning

Results & Conclusion

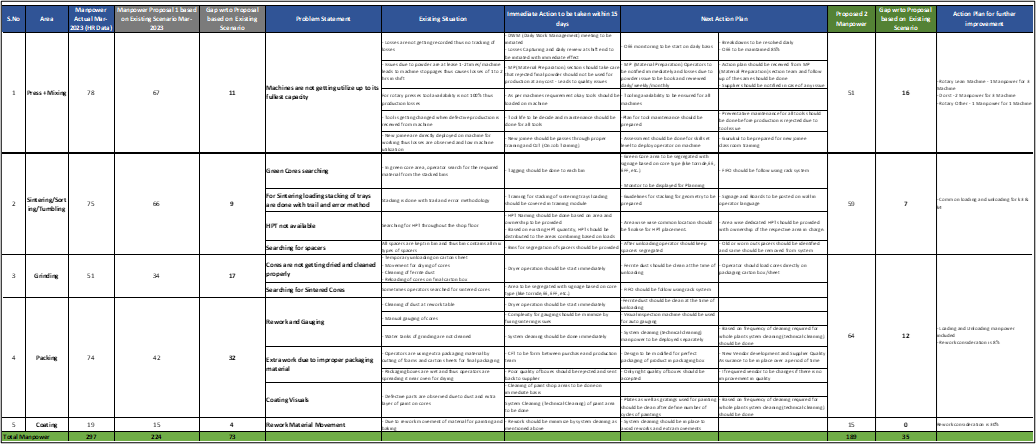

After doing analysis and evaluation following results were obtained –

- Improved productivity by 59.49%.

- Multi-manning to address low utilization of manpower.

- Layout modification for reduction of motion-loss NVA in some areas.

- Dashboards for future planning as per demand & as per working lines.

- Improvements and Suggestions

- Safety related Improvements suggested like usage of Face mask and Hand gloves in Press Shop and Sintering area.

- FIFO system implementation in the Green Core storage area rigorously.

- Implementation of project at site was done by verifying the manpower summary generated by the monthly dashboards and providing the client guidelines for usage of Area wise Monthly Dynamic Dashboards.

- Actionable points given to the client to get immediate improvements.

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?