Streamlining Operations and Resource Utilization in Automotive Component Manufacturing Industry

This case study delves into the journey of a distinguished automobile components manufacturer and supplier with 19 years of industry experience. Renowned for producing top-tier Motorcycle Chassis and Welded Sub-Assemblies, the company aimed to elevate its operational excellence and resource utilization. By implementing advanced techniques such as Predetermined Motion Time System (PMTS), the organization streamlined work content measurement, ensuring precise work distribution and line balancing through insightful man-machine charts. The case study highlights the successful eradication of waste and non-value-added activities, resulting in heightened productivity.

Key Points

- Work content measurement using PMTS technique of their identified areas.

- Work distribution/ line balancing with man-machine chart.

- Eliminating waste and nonvalue-added activities.

- Suggestion for low-cost automations

- Improving the effective utilization or optimization of resources.

- Improvement & suggestions for making existing system better.

- Manpower utilization & Capacity calculations.

Client's Challenge

- Work Standardisation using PMTS techniques.

- Dashboards for production planning as per demand.

- VA/NVA analysis on current working conditions

- Identify true potential capacity of plant.

- Low manpower utilization.

- Layout Modification

PMI's Approach

The study was organized in a 3-stage process:

- Data Collection - Video shooting of all activities on the line.

- Estimation & Data Analysis – Basic MOST estimation, work distribution, dashboard preparation, VA/NVA analysis.

- Results and Conclusion – Area wise Dashboards for Planned production, fatigue reduction, improved productivity, improved manpower utilization, identification of NVA work content.

Involvement of Associates –

- PMI – 1 Project Manager, 2 Engineers.

- Client – 2 Project Co-ordinators.

Data Collection:

- Plant Round with CFT to understand the scope of work.

- Recording videos of activities carried in various areas.

- Interaction with client to understand process from videos.

Data Analysis:

- Preparation of elemental details using PMTS technique & validation by client.

- Analysis (Work distribution/VA-NVA identification) for manpower calculation, optimum manpower utilization & identifying capacity.

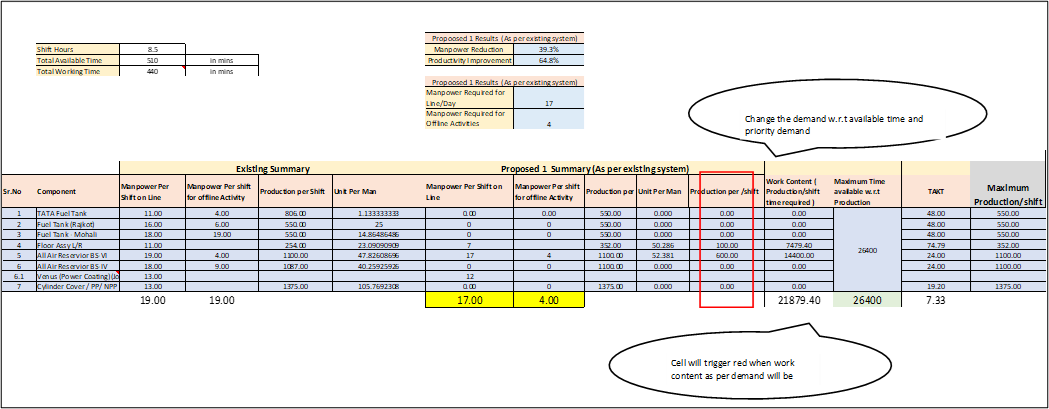

- Dashboard preparation for production planning as per demand.

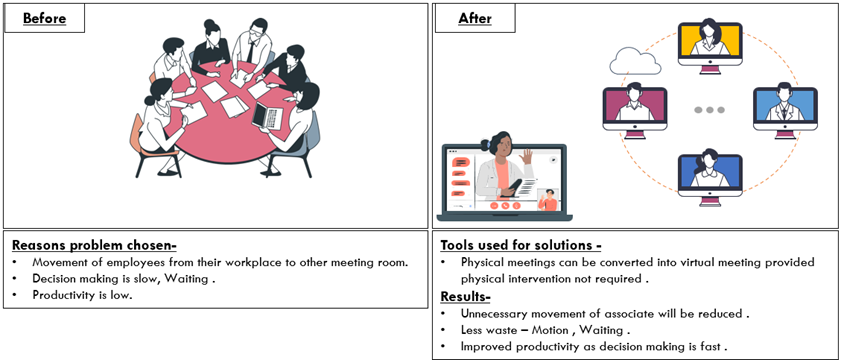

- Improvement & suggestions for making existing system better.

Area wise Dynamic Dashboards for Resource Calculation

Results & Conclusion

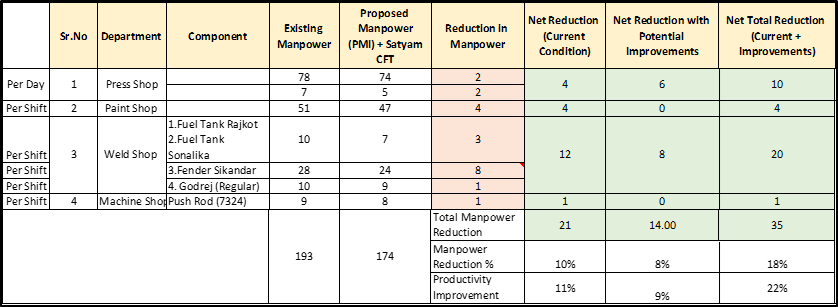

After doing analysis and evaluation following results were obtained –

- Improved productivity by 22%.

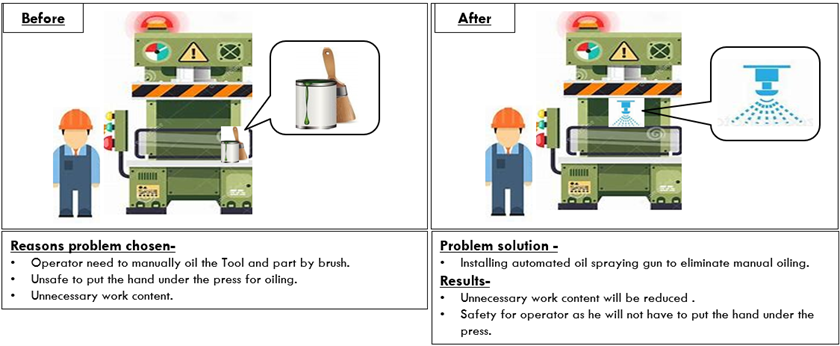

- Fatigue reduction by rotation of operators in between lines & by introducing low-cost automation.

- Dashboards for future planning as per demand.

- Kaizen Suggestion for further improvement.

Overall Manpower Summary

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?