Automotive Component Facility Study

AUTOMOTIVE INDUSTRY JIT Validation

Throughput Validation & Transportation Study

Key Points

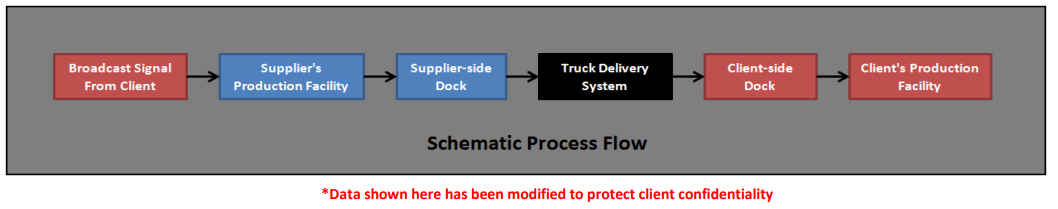

- Validate JIT Process

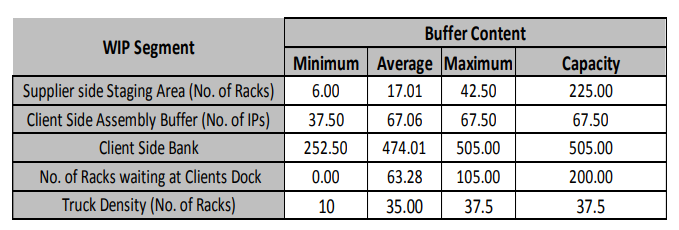

- Analyze Truck Delivery System

- Plant to Plant Logistic Analysis

Client's Challenge

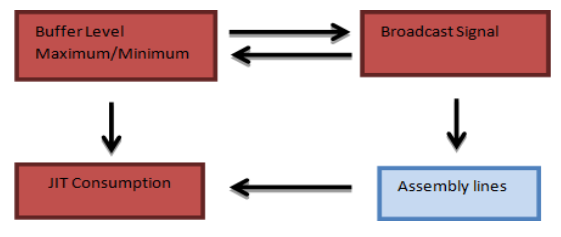

- Evaluate system capability to support Client's Broadcast and JIT consumption

- To Decide number of Trucks, Truck Density and Delivery time

- Tipping point of increasing number of Trucks vs. decreasing Truck Density in order to meet JIT consumption

PMI's Approach

- Analysis of Data and Verification of Baseline Model

- Sensitivity analysis on number of Trucks

- Quantify Impact of Broadcast Repair time on System

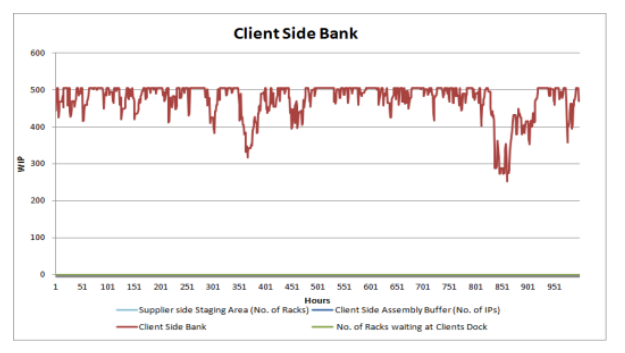

- Buffer recovery time analysis

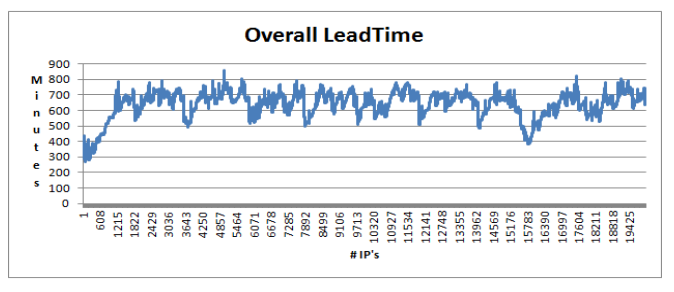

- Lead times analysis

Findings & Recommendation

- AS-RS System is not required

- Identified circumstances that can cause the client's buffer go

below minimum level - Recommendation

- Permissible maximum Down "Time" on production

system without affecting the throughput - Number of truck drivers for various scenarios

- Truck density to meet the expected Throughput

- Permissible maximum Down "Time" on production