A PMTS-Driven Approach to Enhancing Setup Activities in Steel Manufacturing Industry

This case study centers around an Indian steel manufacturing company operating across multiple locations. Focused on optimizing setup activities, the company adopted the Predetermined Motion Time System (PMTS) technique. By meticulously measuring setup processes, capturing losses, and comparing ideal versus actual setup times, the study aimed to identify areas for improvement.

Key Points

- Setup activity work measurement using PMTS technique

- Capturing losses

- Ideal Vs actual setup time

- Suggestion for Improvements

Client's Challenge

- Measurement of actual setup time

- Activities / Losses identification

PMI's Approach

The study was organized in a 3-stage process:

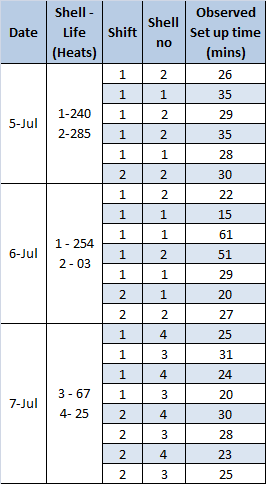

- Data Collection – Video shooting of all activities under scope for 6 days.

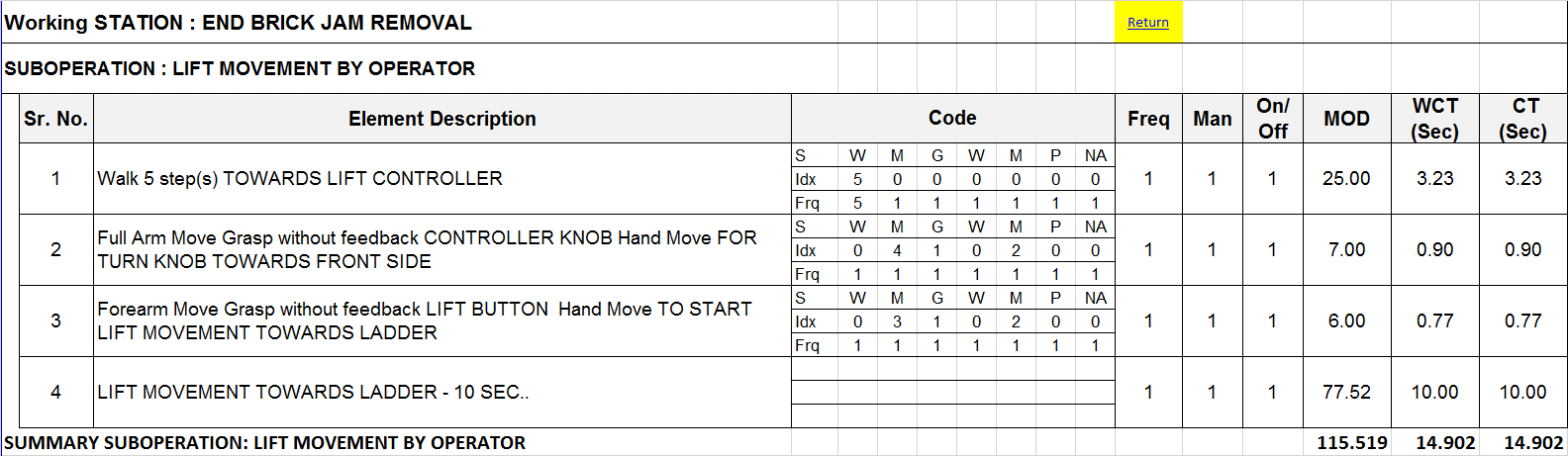

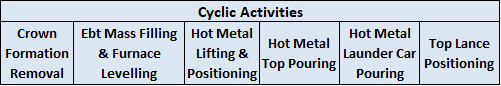

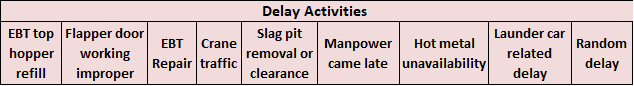

- Estimation & Data Analysis – Estimation using PMTS Technique ,Validation by client and data analysis .

- Results and Conclusion - Improved productivity, Improved manpower utilization, identification of NVA work content.

Involvement of Associates –

- PMI – 1 Project Manager, 3 Engineers.

- Client – 2 Project Co-ordinators.

Data Collection:

- Visiting client site and performing CFT formation and site round.

- Data collection in person observations of all activities under scope with more than 70 observations per day considering peak and off peak timings.

- Interaction with client to understand process and timely observations.

Data Analysis:

- Preparation of excel sheet using work sampling & validation by client.

- Analysis (Work distribution/VA-NVA identification) for manpower calculation, optimum manpower utilization & identifying capacity.

- Dashboard preparation.

- Improvement & suggestions for fatigue reduction & making existing system better.

Results & Conclusion

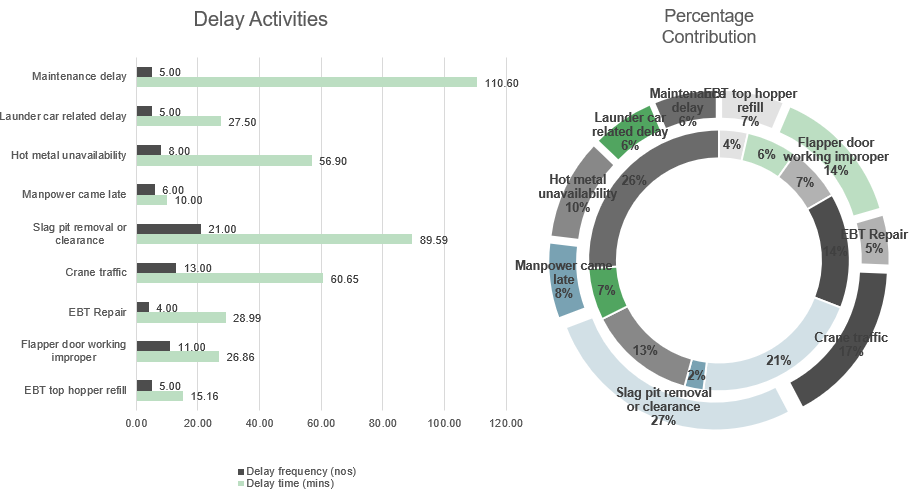

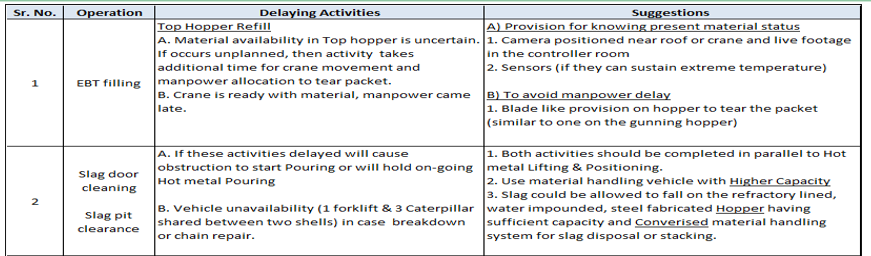

After doing analysis and evaluation following results were obtained –

- Losses contribution of activities

- Improvement and recommendations for making existing system better.

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?