Introduction

Sequencing is the unsung maestro of a finely tuned production symphony in automotive manufacturing. Every car, with its set of features, colors, and trims, needs to reach the correct station, at the correct moment, in the correct sequence. Mess this rhythm up, and the entire production line starts to stumble. A top international automotive manufacturer, with a reputation for building several variants of vehicles on common lines, struggled to sustain this fine balance.

In order to address the problem, the client sought Production Modeling India (PMI) help in modeling a sequencing buffer system that was able to absorb variation and minimize sequence violations—without trading off throughput. PMI used Simul8 to run an extensive study of feasibility to ascertain the optimum configuration and control logic of the buffer.

Client's Challenge

• Determine if a buffer system would be able to maintain the necessary sequencing constraints.

• Determine the number of sequence violations happening in existing operations.

• Suggest logic or structural modifications to reduce or eliminate these violations without reducing production flexibility.

In an environment where even minor deviations can cascade into rework, delays, or increased cost, a strategic fix was essential.

Sequencing Buffer Simulation with Simul8 Streamlines Vehicle Flow from Paint to Final Assembly

PMI’s Simulation Approach

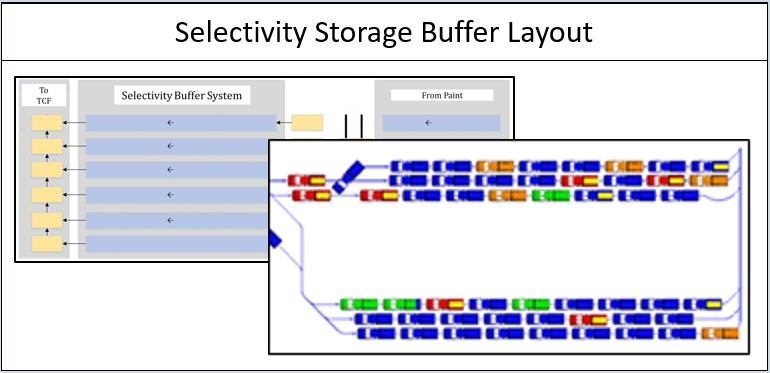

PMI developed a detailed simulation of the sequencing process using Simul8, modeling the full vehicle flow from the paint shop to the final assembly, including buffer transitions and routing logic. Key steps included:

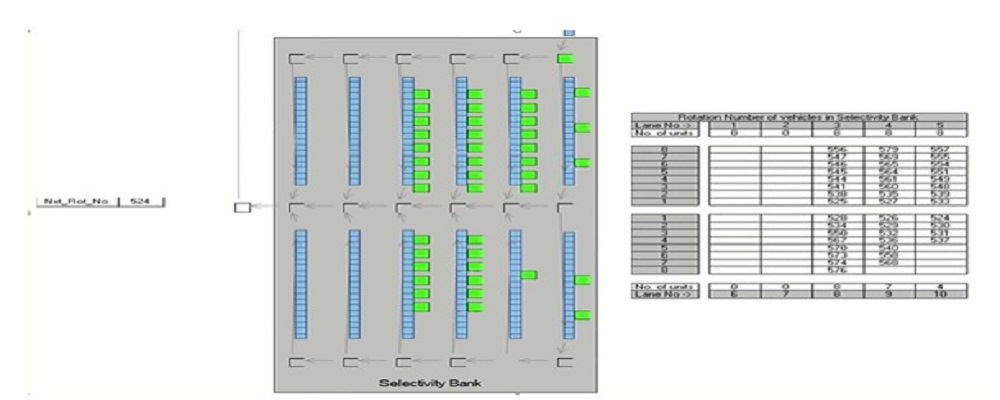

Built a digital twin of the sequencing buffer and vehicle flow logic.

Integrated downstream operations from paint to finish shop, recording movement constraints, dwell times, and buffer behavior.

Tracked system throughput, time-in-state plots, and buffer fill.

Recorded and analyzed sequence exit violations across different operating scenarios.

Performed multiple scenarios by altering model mix, buffer size, and sequencing logic to identify the most stable setup.

Findings and Recommendations

The simulation unveiled obvious findings:

• Average 300 cars per day were violating the preferred sequence due to route logic constraints and unbalanced buffer fill.

• Three parameters—buffer size, model mix distribution, and entry logic—were discovered most significantly to impact sequence stability.

• PMI suggested a new model mix that was balancing flexibility with sequencing precision and minimized violations without limiting product variety.

• The ideal size of the sequencing buffer was established to allow for free flow but preserve the proper order of output.

• Logic changes were recommended to avoid starvation and blocking at strategic points of transfer.

Conclusion

Sequencing in car assembly is a mission-critical puzzle, with the wrong piece at the wrong moment bogging down the entire process. Using a carefully constructed simulation with Simul8, PMI enabled the customer to not only see the problem but also create a data-based solution.