A Comprehensive Case Study on Efficiency and Resource Optimization in Plywood Manufacturing Industry

Discover how a leading plywood manufacturer excelled by diversifying its product line, including innovative flexible plywood and fire-retardant solutions. A strategic approach hinged on methodologies like PMTS, Time Study, and Production Study drove operational efficiency. Waste reduction, resource optimization, and dashboard-integrated planning led to increased productivity. Insights from waste analysis refined processes iteratively, unveiling the plant's true capacity and addressing low manpower utilization. A story of excellence and innovation, cementing the company as a plywood industry leader.

Key Points

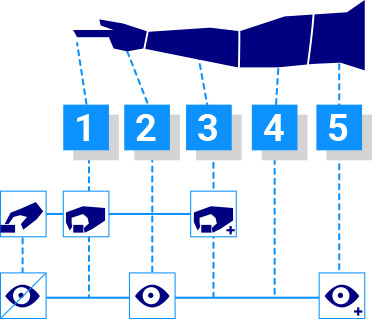

- Work Content Measurement using PMTS technique, Time Study or Production Study of in-scope areas.

- Work Standard Development

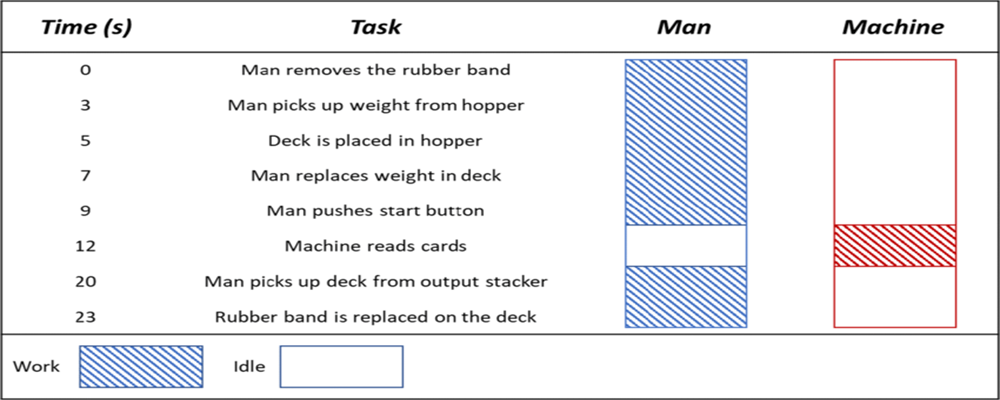

- Cycle Time, Manpower & Capacity Calculation

- Eliminating Waste and Non-Value-Added Activities to increase productivity.

- Improving the effective Utilization or Optimization of resources

- Improvement and Suggestions for making existing system better.

Client's Challenge

- Reduction in manpower fatigue.

- Dashboards for production planning as per demand.

- Muda & Muri analysis for further improvement.

- Identify true potential capacity of plant.

- Low manpower utilization.

PMI's Approach

The study was organized in a 3-stage process:

- Data Collection - Video shooting of all activities on the line.

- Estimation & Data Analysis – PMTS technique estimation, work distribution, dashboard preparation, Muda & Muri analysis.

- Results and Conclusion – Dashboards for future planning, fatigue reduction, improved productivity, improved manpower utilization, identification of NVA work content.

Involvement of Associates –

- PMI – 1 Project Manager, 2 Engineers.

- Client – 2 Project Co-ordinators.

Data Collection:

- Video recording of the activities carried in Direct and Indirect areas of the in-scope areas.

- Interaction with client to understand process from videos.

Data Analysis:

- Preparation of elemental details using PMTS technique & validation by client.

- Analysis (Work distribution/VA-NVA identification) for manpower calculation, optimum manpower utilization & identifying capacity.

- Dashboard preparation for production planning as per demand.

- Improvement & suggestions for fatigue reduction & making existing system better.

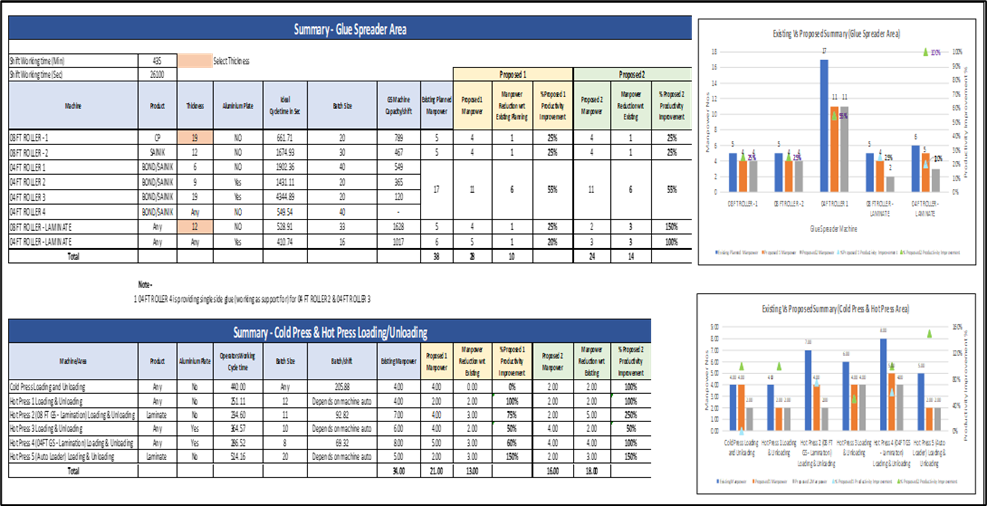

Production Planning Dashboard

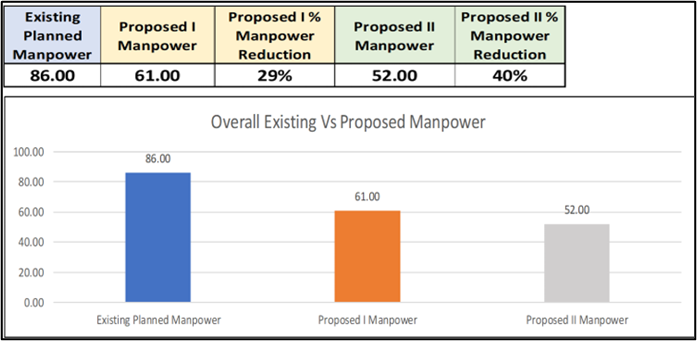

Results & Conclusion

After doing analysis and evaluation following results were obtained –

- Improved productivity by 65%.

- Fatigue reduction by rotation of operators in between lines.

Overall Manpower Summary

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?

Recent posts