Automotive Facility Study (Body Shop)

AUTOMOTIVE INDUSTRYDesign (Process Flow) validation

Process Flow Design Validation - Body Shop

Key Points

- Identification of potential bottlenecks in

proposed process flow - Redesigning of process flow to alleviate

bottlenecks

Client's Challenge

- The body shop plans to introduce new model C while

producing existing models A,B - Each body type requires its own special pallet type

- the proposed empty pallet release process flow to:

1. Ensure pallets are released efficiently in production

sequence while maintaing current production levels

2. Minimize empty pallet set-asides

PMI's Approach

- Analysis of Data and Verification of Baseline Model

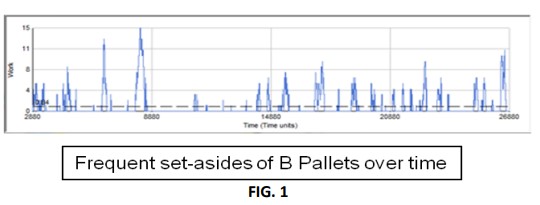

- Identification of bottleneck by measuring pallet set asides in return loop section

Findings & Recommendation

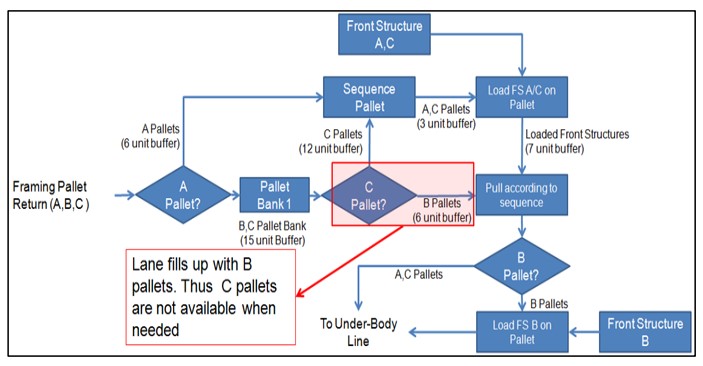

- Proposed process flow was ineffective because:

- Facility has to manually “set-aside” excess B type pallets to

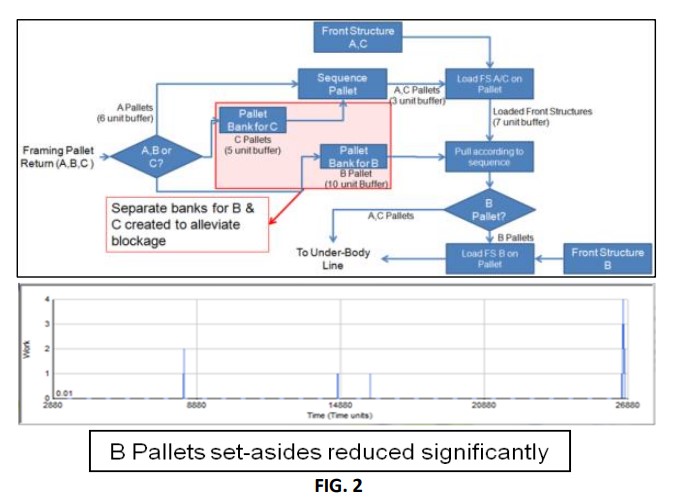

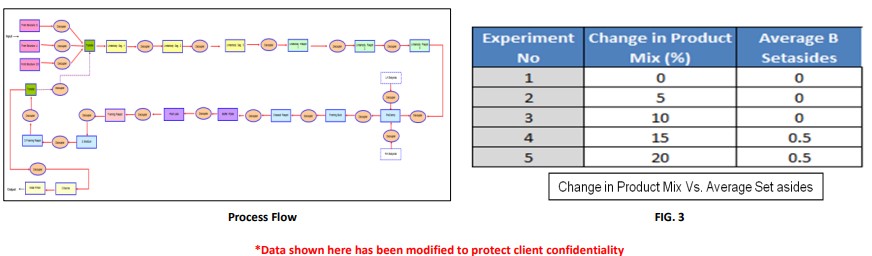

alleviate blockage(see Fig. 1) - Revised the process flow in pallet return loop to minimize

manual set-asides(see Fig. 2) - Cost effective solution - 25% savings in buffer space while

maintaining current production - Revised process flow found to be able to handle up-to 20%

variation in product mix(see Fig. 3)