Work Standard Development in Loom Machine Manufacturing Industry

This comprehensive case study documents the transformative journey of a prominent global manufacturer & supplier in the realm of plastic woven fabric machinery. The study, initiated by an analysis of assembly line operations, delves into intricate details to optimize production processes and manpower utilization. This case study presents a holistic blueprint for enhancing production efficiency and workforce optimization in the dynamic landscape of plastic woven fabric machinery manufacturing. By strategically leveraging techniques such as PMTS, work distribution, and line balancing, the company solidified its global standing while making substantial strides in circular loom machine production.

Key Points

-

Setting up assembly line as per standards.

-

Sub assembly line validation and planning for unidirectional flow.

Client's Challenge

-

Loom machine assembly conveyor line study.

-

Sub assembly line optimization.

PMI's Approach

- At the time of kick of meeting, client cross functional team was formed.

- Understanding process, Video data collection & Elemental details preparation for observed activities using PMTS technique.

- Data requirement sent to area owners for logs of various activities.

- Validation for all elements & process is done by client.

- Analysis and work content calculation using PMTS technique & involving client for validation & confirmation. Bottleneck identification, Manpower & capacity calculations.

Results & Conclusion

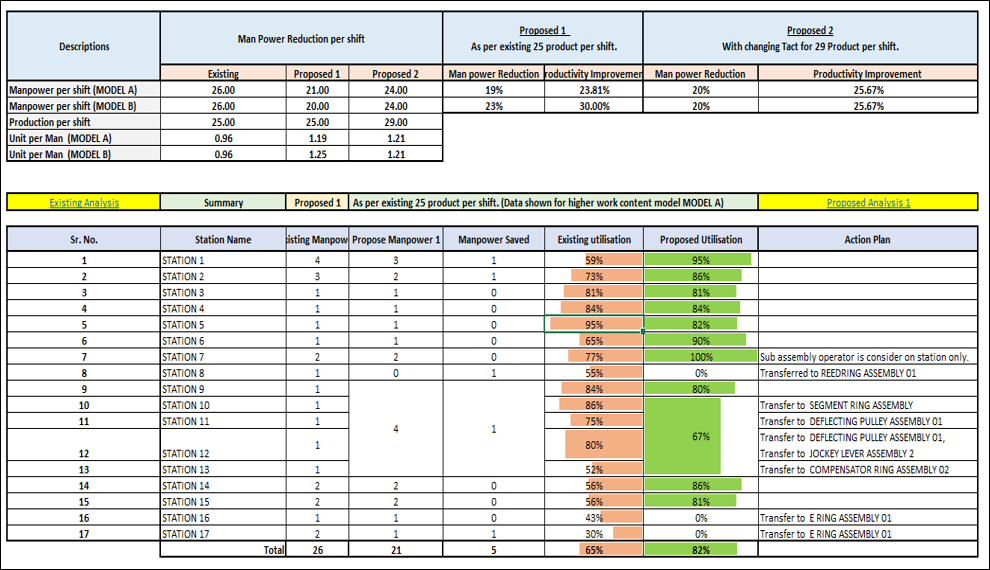

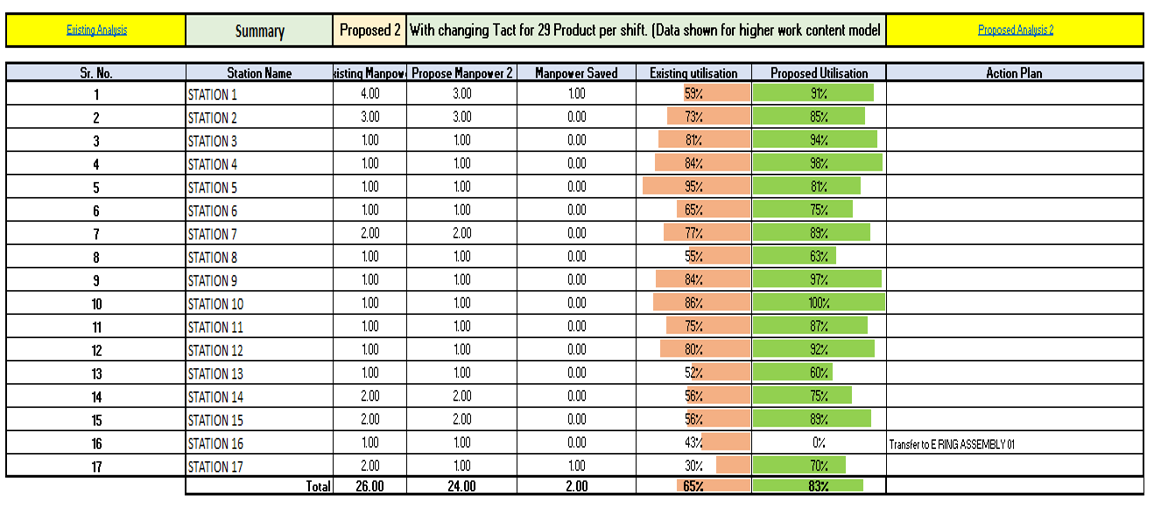

- Preparation of elemental details from the videos recorded for the Assembly line of both models. Assembly line balancing w.r.t existing condition.

- Find out the bottleneck.

- Following is loom machine line balancing with Proposed 1 and Proposed 2 Condition.

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?