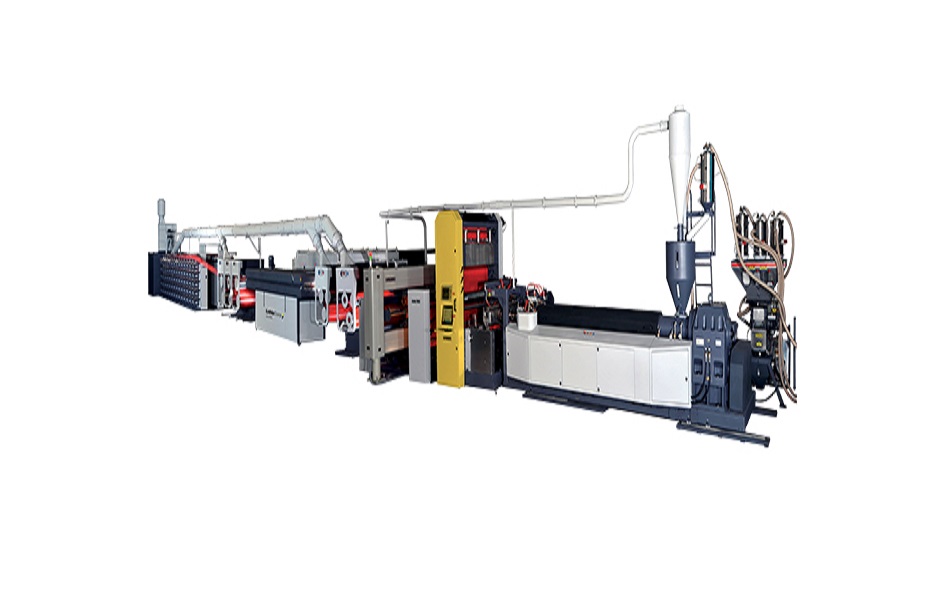

Work Standardization and Industrial Engineering Study for Leading Textile Machine Manufacturer in India

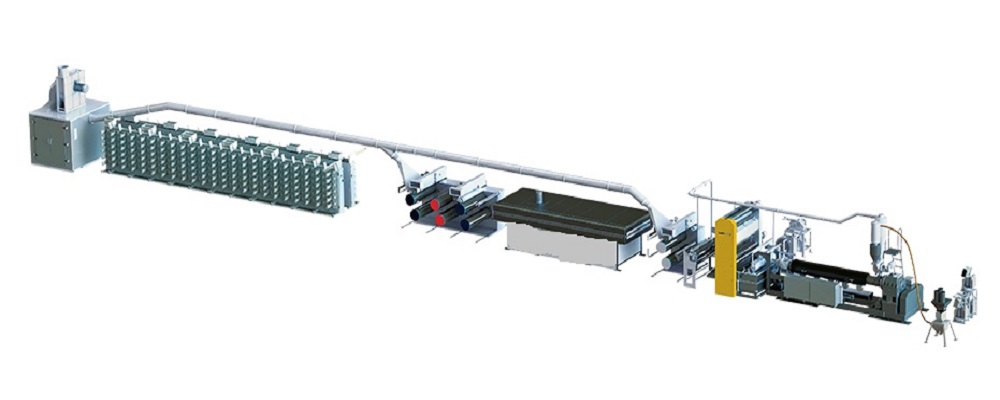

Leading textile machine manufacturer is having a challenges of man power deployment and work standardization with respect to the varying market demand. Hence client wants to conduct IE Study for work standardization in Tapeline Machine Assembly Shop

Key Points

- Work Content Calculation for Tapeline Assembly Unit

- Work Standardization using SWCT

- Increasing per month Capacity

- Manpower Deployment for varied demand

Client's Challenge

- Product is huge in size and cycle time is high

- Product itself is assembly of around 6 Nos of Machines/Units

PMI's Approach

Analysis

1. Project Kick Off

- Existing Facility Walk Through

- CFT Formation

2. Data Collection

- Team of 6 Engineers – Data Collection in 3 Shifts

- Base Model Data Collection

- Exclusive activity data collection for other model

3. Analysis

- Work Content Estimation

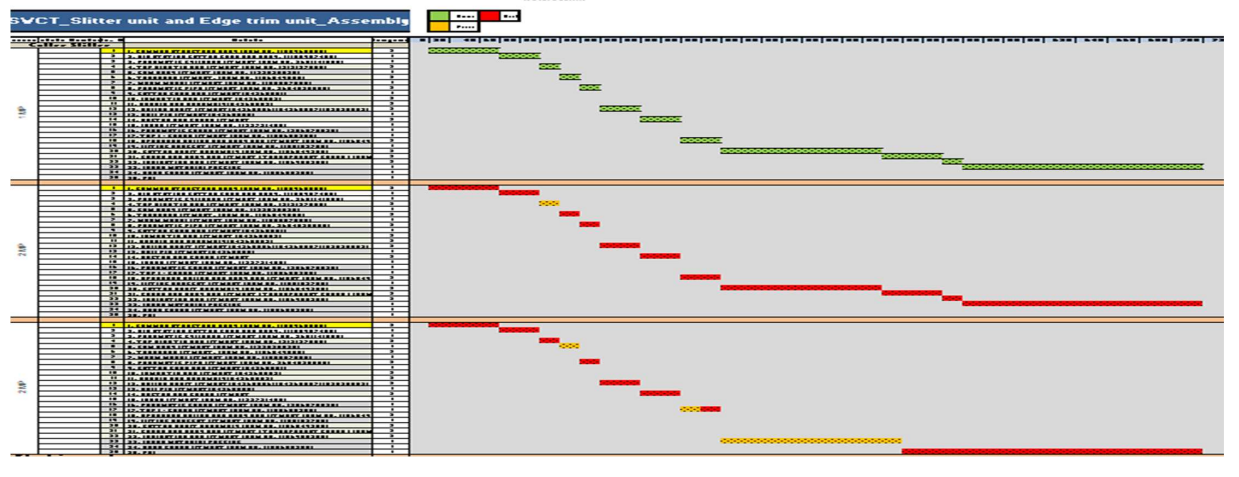

- SWCT

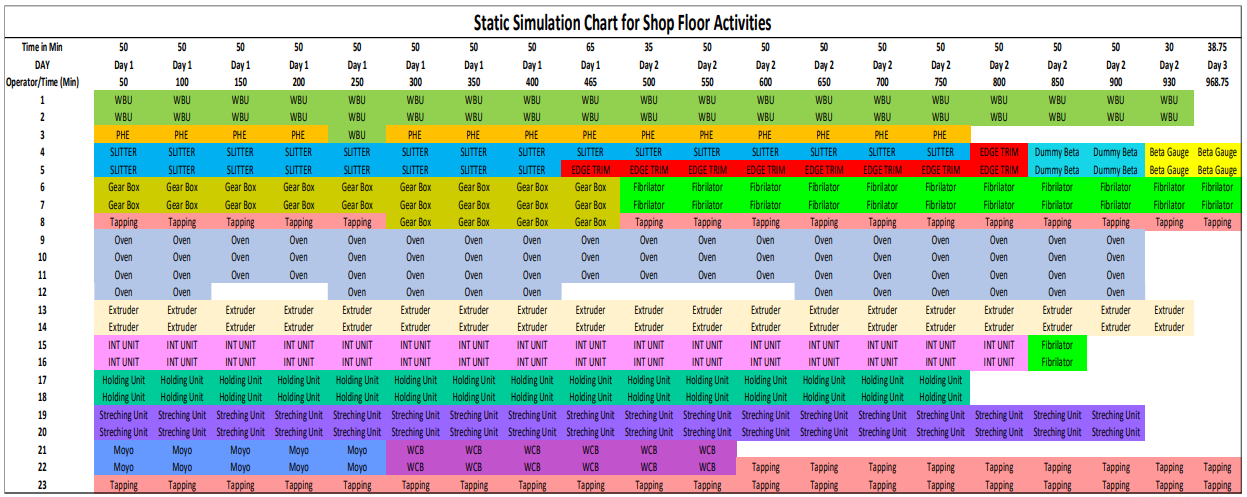

- Work Distribution using Static Simulation

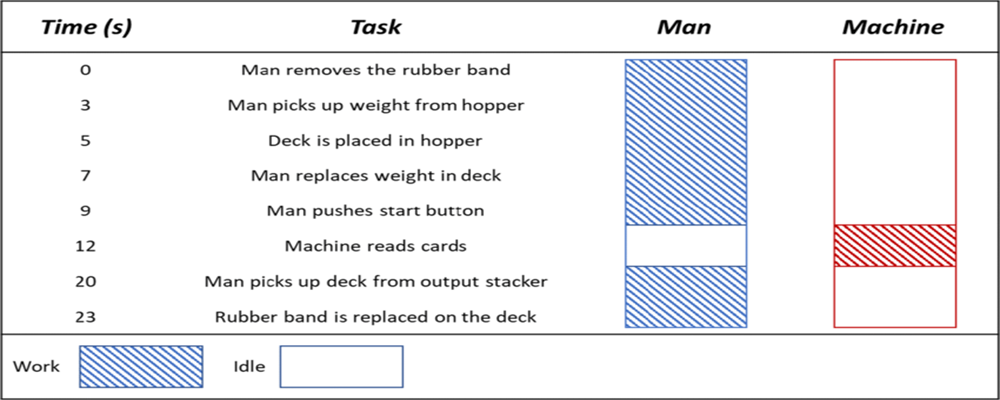

SWCT - Standard Work Combination Table

Static Simulation for Shop Floor Activities for 12 Nos. Products/Month

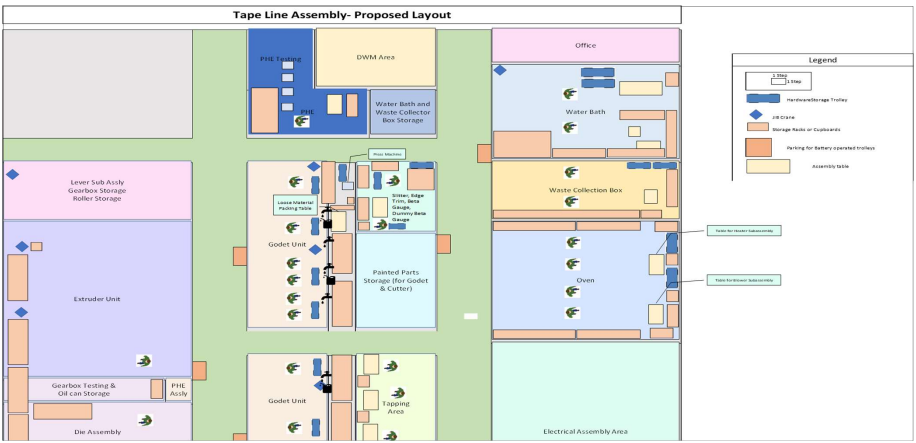

Proposed Layout

Findings & Recommendations

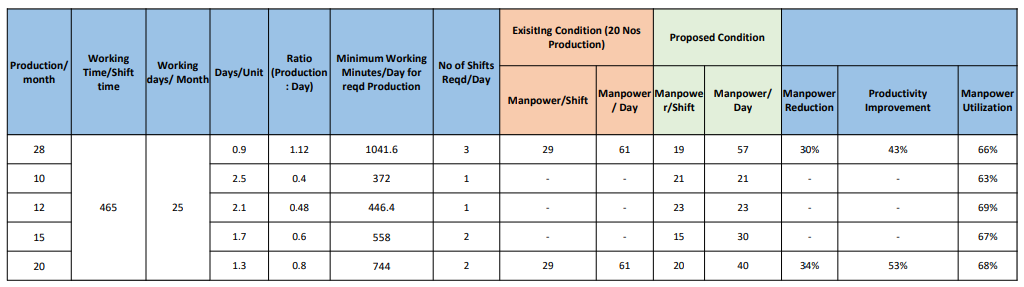

- Cycle time improved from 1.3 days/unit to 0.9 days/unit

- 30% Manpower Reduction and 43% Productivity Improvement

- Deployment of operators, as per study, to be done so that the unit runs efficiently.

- Materials and Tools availability to be ensure at each workstation

- Layout Modification are required as suggested.

- Jib crane for Water Bath Unit

- Material Storage units to be provided near unit (within 15-20 steps) (All Units)

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?

Recent posts