Stopwatch Time Study Enhances Efficiency and Production for Prominent Bike Manufacturer in India

The client is a prominent Japanese multinational manufacturer known for producing motorcycles, marine products such as boats and outboard motors, and other motorized goods. In India, the client holds a significant position as one of the largest manufacturers of bikes. This case study showcases the successful application of stopwatch time study techniques in the automobile industry, resulting in improved efficiency, reduced fatigue, optimized resource utilization, and enhanced production planning capabilities for the client.

Key Points

- Easy and accurate cycle time calculation.

- Interactive sheet linked with formulas for getting dynamic results.

- Manpower calculation on each and every station.

- Improvement points to client to future use.

Client's Challenge

- Reduction in manpower fatigue.

- Identify true potential capacity of plant.

- Calculation of exact work content required to make one unit of product.

PMI's Approach

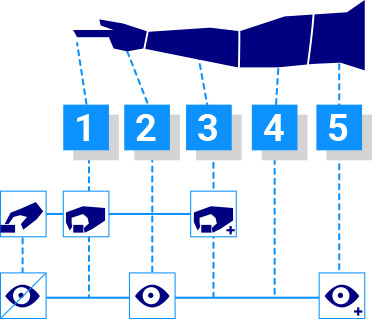

The study was organized in a 3-stage process:

- Data Collection - Video shooting of all activities on the line.

- Estimation & Data Analysis – Stopwatch time study estimation and validation with client team.

- Making client time familiar with stopwatch study technique for easy understanding.

- Results and Conclusion – Sheets for work content estimation, fatigue reduction, improved productivity, improved manpower utilization, identification of NVA work content.

Involvement of Associates –

- PMI – 1 Project Manager, 2 Engineers.

- Client – 2 Project Co-ordinators.

Data Collection:

- Visit to client site and understanding the plant before starting data collection.

- Shooting of videos using high tech cameras for better capturing of data collection.

- Interaction with client to understand process from videos.

Data Analysis:

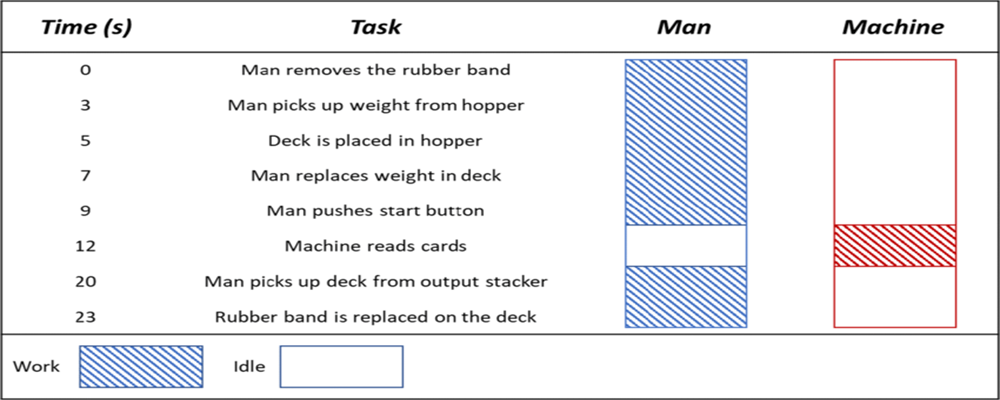

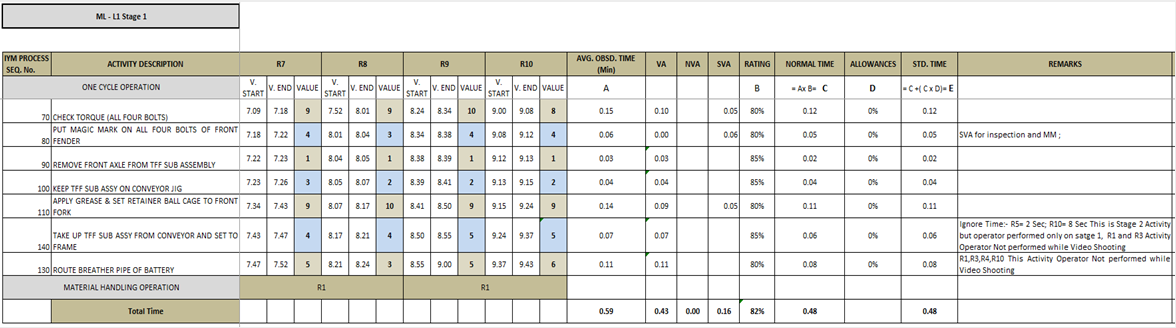

- Preparation of sheets of stopwatch time study multiple readings and validation by client.

- Analysis (Optimum manpower utilization & identifying cycle times and capacity of plant).

- Work content sheet preparation for cycle time as per demand and adding allowances to it.

- Improvement & suggestions for fatigue reduction & making existing system better.

Results & Conclusion

After doing analysis and evaluation following results were obtained –

- Actual cycle time for operations were obtained.

- Adding allowances to normal cycle helped to optimize production and manpower.

- Sheets for future planning as per demand & as per working lines.

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?