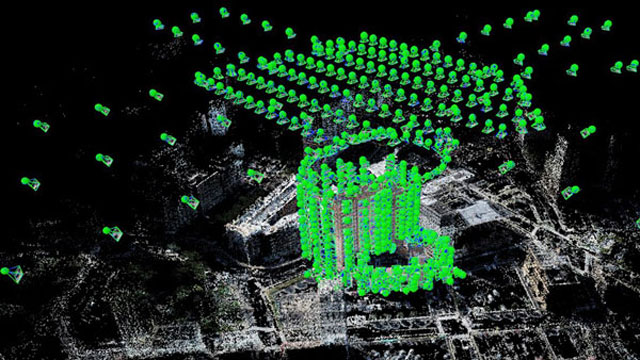

Simulation of an End-of-Line Testing Area for a Leading Vehicle Manufacturer

A leading global automotive company wanted to right-size the number of drivers required for maneuvering vehicles in the End-of-Line section of its automobile production ensuring the desired target is met.

Key Points

- Automobile Industry

- AutoMOD

- End of Line

- Driver Utilization

- Capex Study

Client's Challenge

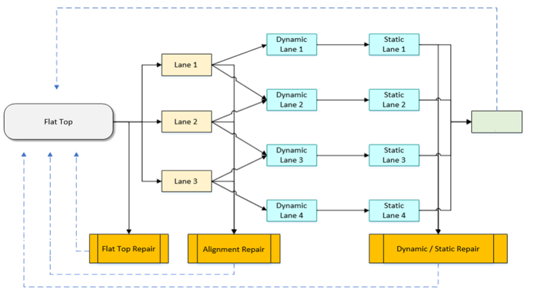

- Identify and alleviate bottlenecks in the system

- Recommend ideal number of car drivers, process stations and parking spaces in the End-of-Line section

- Analyze the impact of repair rates on system throughput

PMI's Approach

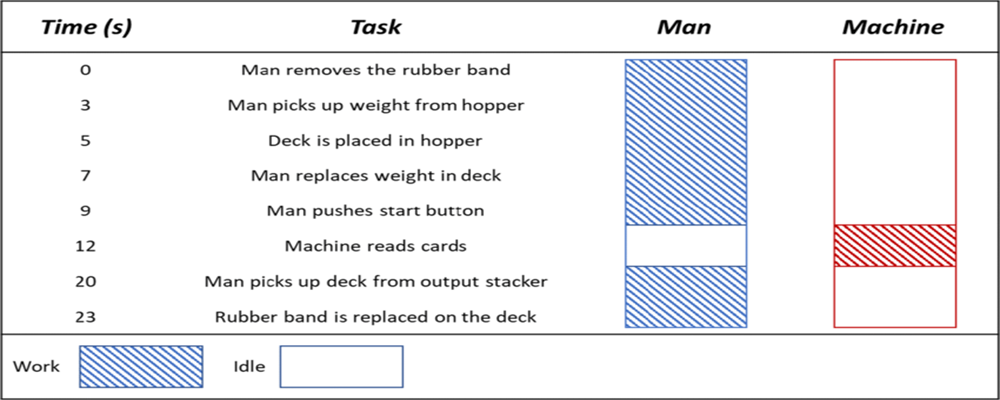

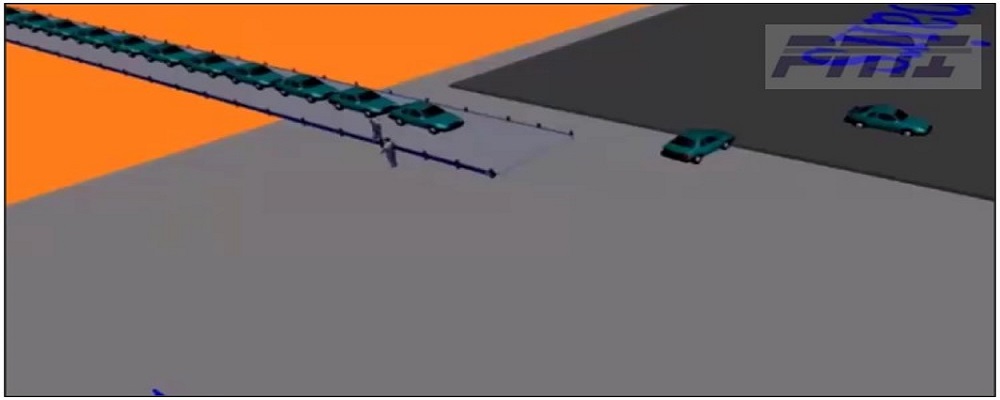

- The station cycle times were statistically modeled based on real-time data from client

- The detailed process was modeled in Simul8

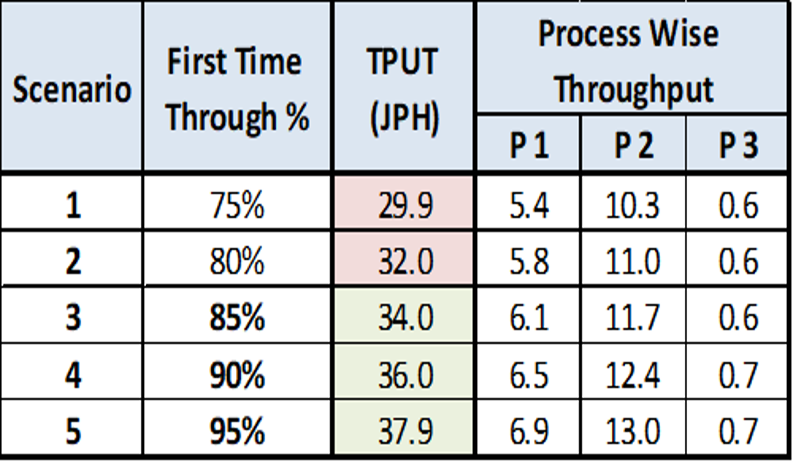

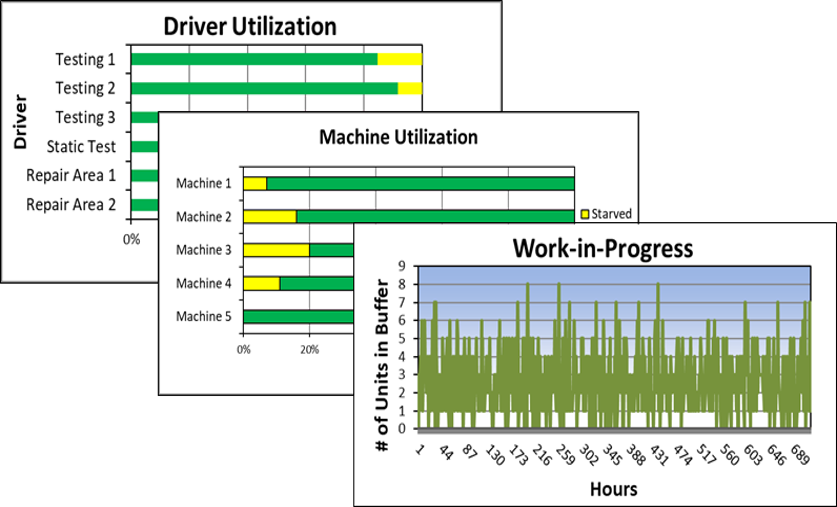

- The queue sizes, driver and equipment utilizations were studied while varying first-time-through rates

Findings & Recommendations

The system was able to produce just 65% of its target production.

We found that the number of calibration test drivers were the first constraint in the system

- Addition of 2 more drivers improved the throughput by 30%

The number of body repair stations were the second constraint in the system

- Improving the cycle time by 50% by addition of labor ensured the throughput is met

A First-time-through sensitivity test showed that a minimum of 75% vehicles should clear the inspection test to meet target production

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?