Simulation of an Automobile Plant for a Leading Vehicle Manufacturer

A leading global automotive company planned to add new body and paint shops in the facility to ramp up its production.

They wanted to study the behavior of the individually designed systems as a whole and define routing rules, identify buffer sizes between the shops to achieve its production target.

Key Points

- Automobile Industry

- Tecnomatix Plant Simulation

- Bottleneck Analysis

- Buffer Analysis

- Carrier Analysis

Client's Challenge

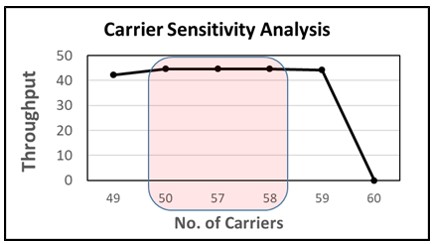

- Identify optimum buffer requirement and carrier counts between Body and Paint, Paint and Final shops

- Recommend conveyor layout with required number of lanes and their parameters to improve routing

- Optimize rules between body shop and paint shop to minimize purge operations in paint shop spray booth

- Optimize rules between paint shop and final shop to rearrange mixed up units to their original sequence

PMI's Approach

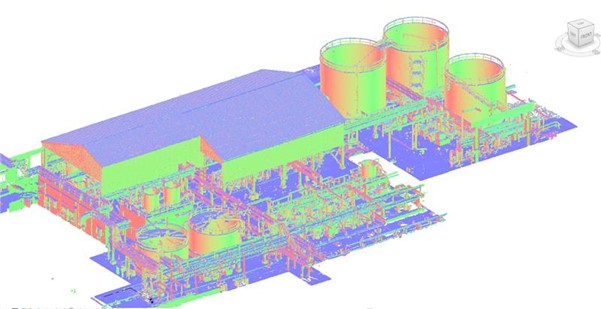

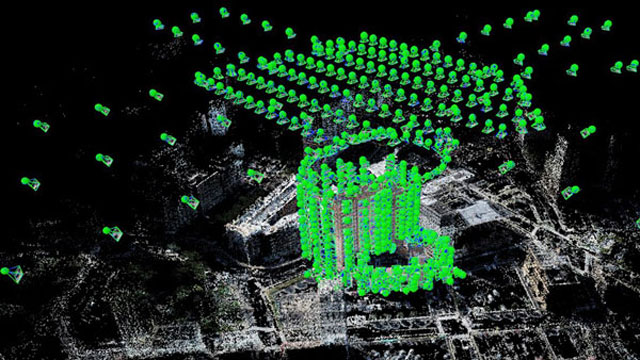

We carried out static analysis, 2D and 3D simulation to study in detail :

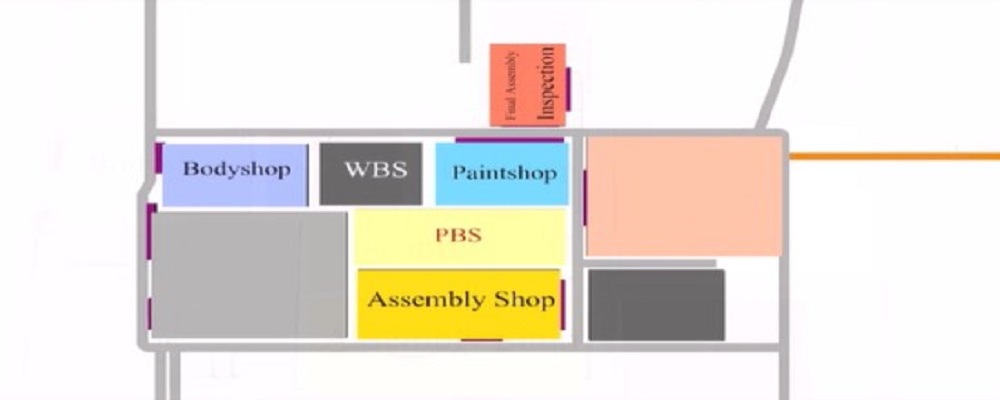

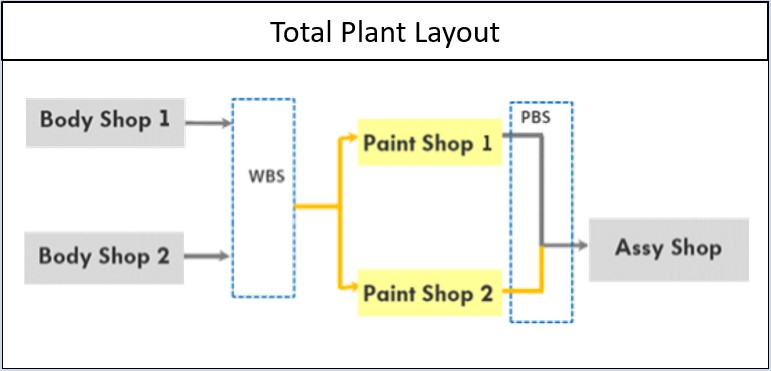

- Body Shop, Paint Shop and Final Assembly separately

- Total Plant combining each shop and intermediate vehicle handling and storing conveyors (Body-In-White Storage/ BIW and Painted Body Storage / PBS)

Findings & Recommendations

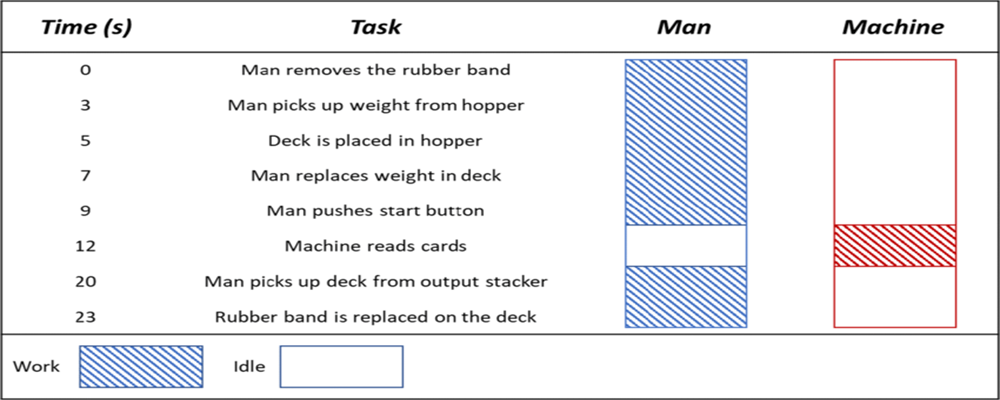

We found that the main bottleneck in the system to be the chassis line in the assembly shop with the design buffer system and carrier counts.

- Increasing the door loop conveyor capacity by 20 units improved the throughput

- Using the recommended number of carriers and the conveyor layout for WBS and PBS helped achieve the target throughput

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?