Maximizing Efficiency in Pharma Industry through Industrial Engineering Study

Pharmaceutical industry is a highly innovation driven industry which throughout its history has contributed to the well-being of the humans by providing new medicines to address various diseases and have grown into one of the major sectors in the world. Our client organization which works to provide solution to their client based on their requirements. The pharmaceutical industry is a complex industry which involves several actors who practice optimization at different levels. It would be interesting to understand the phenomenon from the perspective of the Big Pharma’s since they are the main drivers of change in the innovation ecosystem of the industry, leading us to the goal of this case study.

Key Points

- Pooling of skilled resources for peak load.

- Multiskilling in between department can be implemented for intricated work.

- Communication to clients effectively and effective decision making is important for client demands.

- Time management skills based on the client dynamic requirement and also delivering qualitative output to client.

Client's Challenge

- To increase productivity.

- Eliminating waste and non value-added activities.

- Improving the effective utilization or optimization of resources.

PMI's Approach

- Conducted proof of concept in one part of QA department (Chemical development and formulations) to achieve ‘’More with less’’ using Lean & Time motion study of QA activities.

- Based on the outcome of study the learnings and actions can be implemented across Quality department (broader QA coverage of other OU’s) to maximize the benefits.

What was the Context / Background?

- Virtual Interactions with client QA associates. (25 % of QA Associates interviews are conducted).

- Jointly Time Study conducted for 14 % of QA Associates involved. (Total Count – 80)

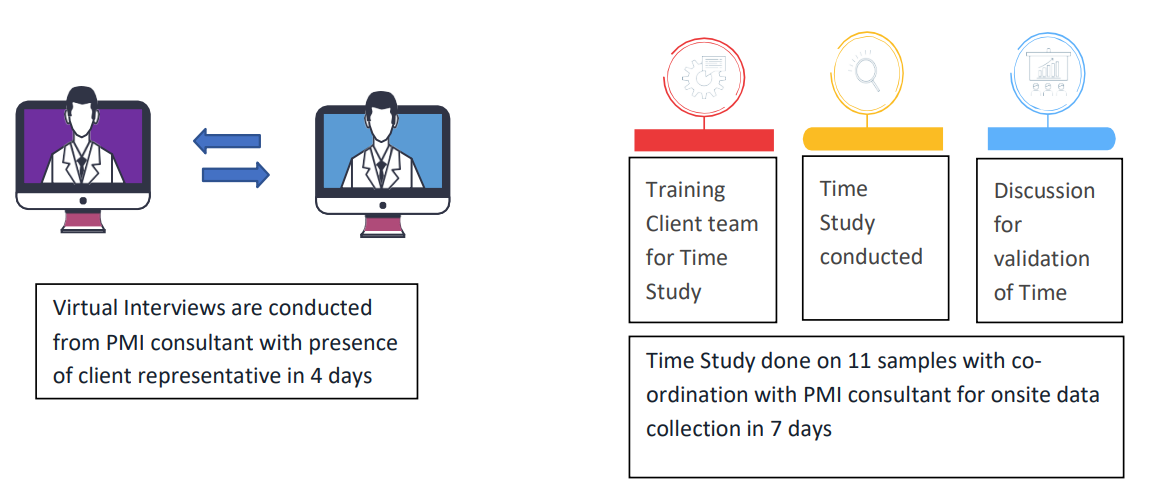

How was it organized and who was involved?

The study was organized in a 3-stage process:

- Data Collection.

- Data Analysis and Estimation.

- Results and Conclusion.

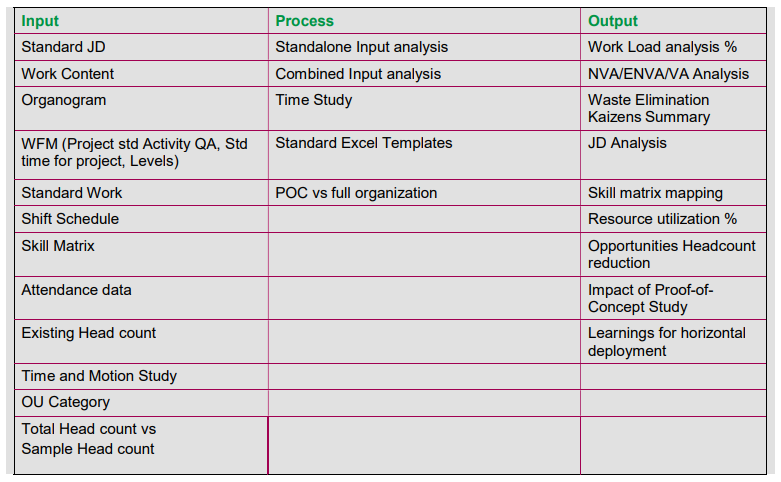

Data Collection – Collection of data from client in standard templates and then organizing the data for analysis and estimation after validation from client.

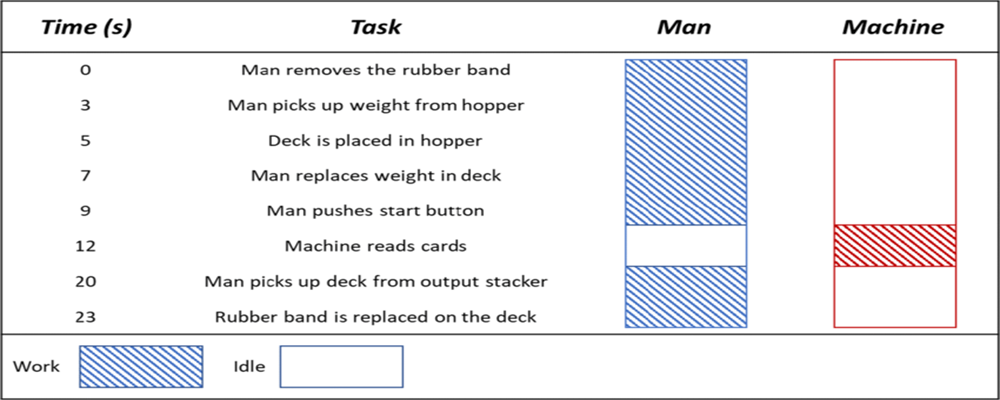

Data Analysis – Using the tools like standalone input analysis, combined input analysis, Time study, POC

vs organization for data analysis.

Results and Conclusion: Optimization of Work force, Areas for removal of nonvalue-added activities, skill matrix and revised organogram, Action plan for further improvements.

Involvement of Associates:

- PMI – 1 Project Manager, 2 Engineers.

- Client – 1 Master Black Belt and 2 Black Belt.

Design of Analysis:

Findings & Recommendations

Has it been evaluated? How successful has it been?

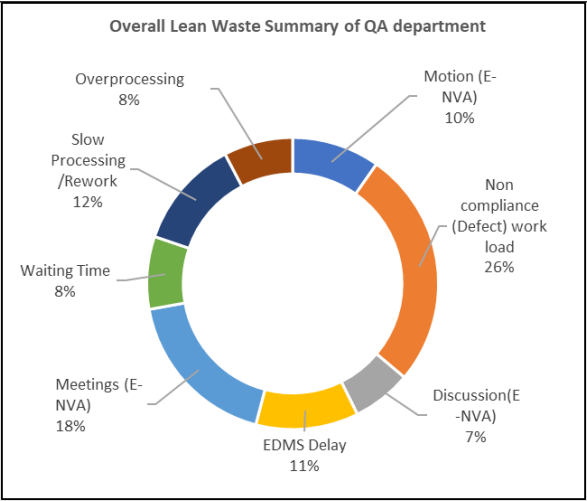

After doing analysis and evaluation following results were obtained:

- 36% of time observed is lost in terms of productivity during analysis.

- The 36% is further sub-classified into 7 types of Lean waste and can be eliminated with action plan.

- Multiskilling of Associates is obtained.

- Opportunities for Head count reduction and resource optimization.

- Restructured organogram.

How did it draw on or contribute to an Optimization of Client Challenges?

- Multiskilling of associates is obtained which can help to shuffle associate during heavy workload.

- Reducing the nonvalue-added activities that can result in resource optimization.

- Headcount can be reduced by 9% of total QA count with increase in productivity.

Future Plans

- Stabilize first and distress the system by implementing 40 Kaizen actions.

- Optimize the manpower headcount as per restructured organogram.

Recent posts