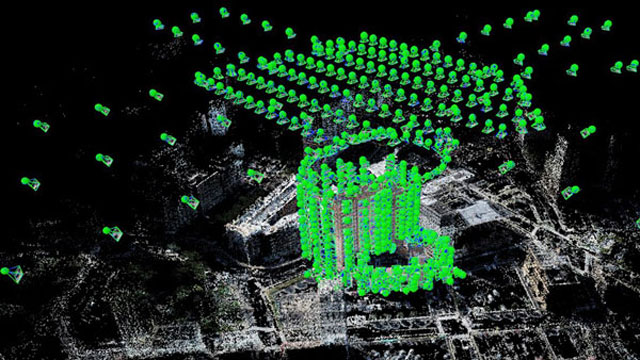

Foundational data for Digital Twin and Industry 4.0

Floor Plans and 3D Revit Model

Strategic Phased Approach

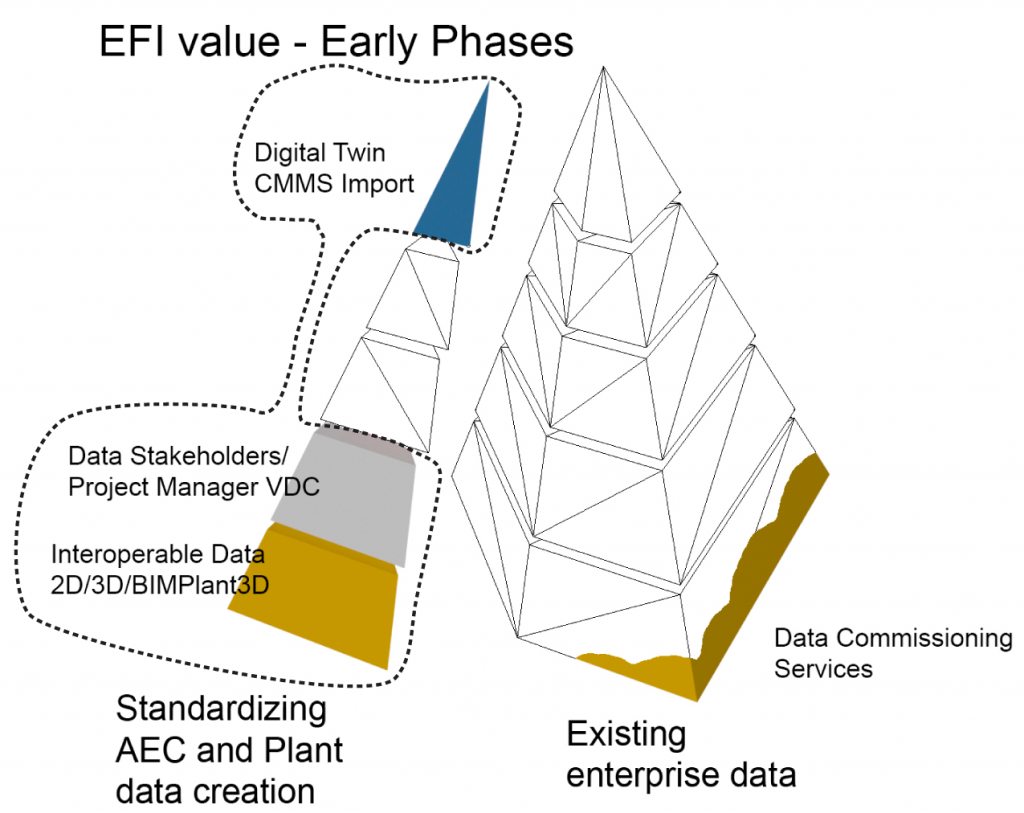

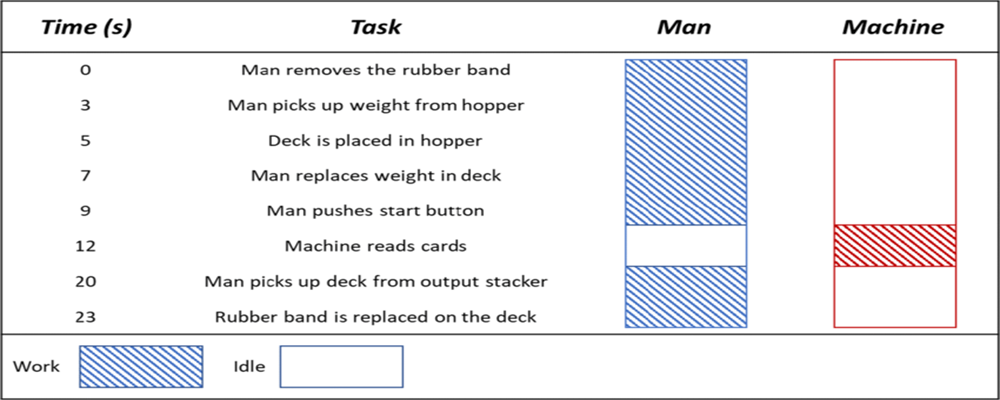

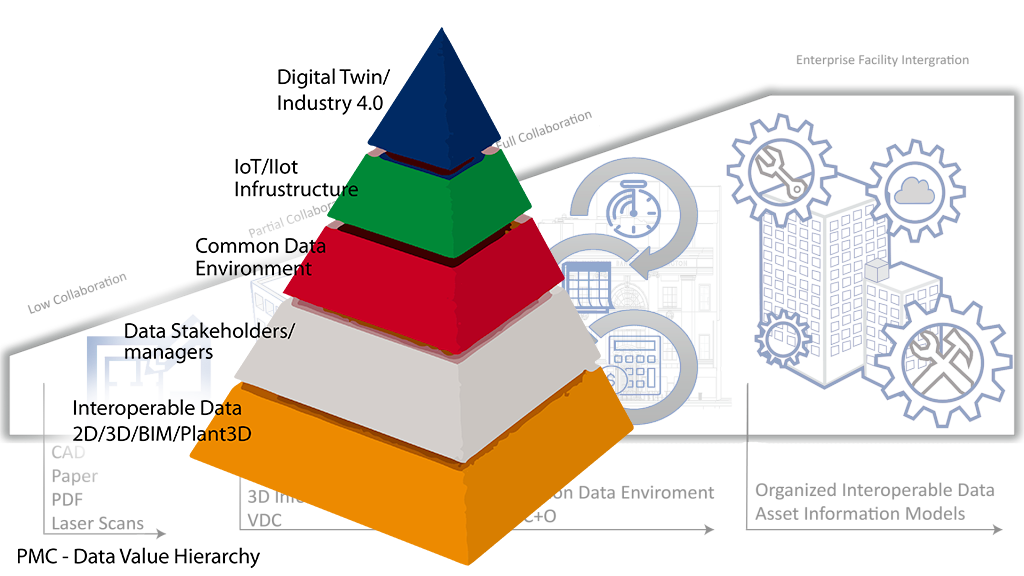

Enterprise Facility Integration (EFI) is a method my teammates and I at PMC have developed to help client’s phase into BIM to FM maturity so that value milestones are defined. Anyone who has held positions in BIM Management or as a VDC Project Manager in the last twenty years understands that corporations adopt BIM incrementally. Adopting BIM practices strategically results in incremental returns. The PMC AEC+O team has developed our process using experience we have gained through managing Architects, Engineers and Construction (AEC) teams migration with BIM tools and data. Using our knowledge, we have created a phased approach to data maturity and a foundation for Digital Twin and Industry 4.0 use cases. These can be used by owners and operators seeking BIM to FM and Digital Factory value. Two helpful tools PMC uses as we phase value for operations and facilities management BIM use cases are the data maturity wedge (Digital Twin flavor) and BIM value hierarchy.

Building a data standard for your highest value

PMC – Data Maturity Matrix

The data maturity wedge was introduced in the UK BIM standard as a key component in a path to iBIM (collaborative interoperable data). It has seen many flavors in different standards, articles, and slide talking points. The wedge is a common expression of an organization’s building data maturity. It represents enterprise record data and all available AEC supply chains. The four levels of information exchange represent data interoperability or lack of opportunities to standardized and exchange information between stakeholders in building life-cycles.

The PMC version of the wedge considers phase four as the integration to Digital Twin and Industry 4.0. The key reason is that all levels of data should consider the highest usage goals. What this means is that when a standard is considered for example, organizing asset documents, being indexed into level four becomes a value. The same can be said for all intermediate forms of data from Revit to CMMS. The unique difference from what the PMC maturity wedge is that it’s not just a high level BIM/VDC viewpoint. The PMC wedge is a search for interoperability beyond the AEC life-cycle. Finding common data value across AEC+O eliminates the biggest problem with digital building/plant floor life-cycles. A large percentage of design and construction data becomes throw-away rather than serve operations. As each form of building or plant floor data becomes interoperable to level four, (the foundation of data usage) the value hierarchy becomes a catalyst for return on investment.

BIM Value Hierarchy

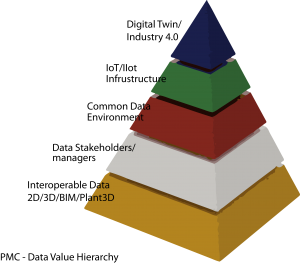

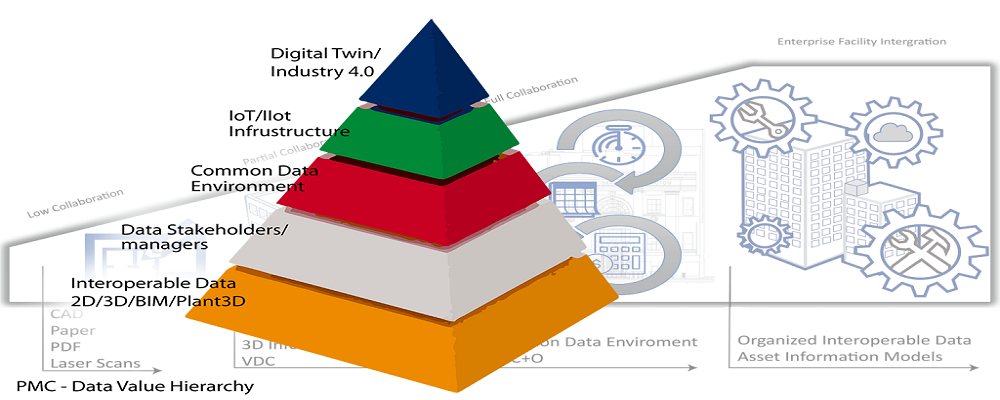

Data Value Hierarchy

PMC’s BIM Value Hierarchy looks very similar to Mazlow’s for a reason. In the same sense a person can’t self-fulfill their needs without a foundation, Digital Twin/Industry 4.0 can’t return value without a foundation. That value needs to be informed by building the foundation from the bottom using standards.

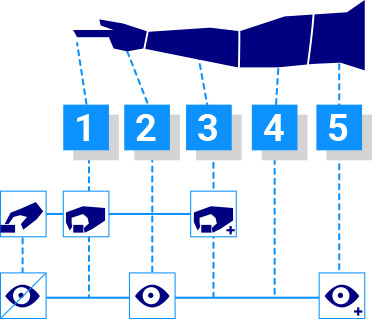

When PMC first starts partnering with a client, one of our first goals is to define the standards base on the usage needs to be fulfilled. In this case our Hierarchy focuses on a high level of value. Since usage and value are at the top of the pyramid, each collection of data, from basic to rich, needs to be interoperable and integrated. There are at least five layers of integration we feel need consideration:

- Digital Twin/Industry 4.0 usage – forecasting, big data analysis, etc.

- IoT/IIoT Infrastructure

- Common Data Environments

- Trained Data Managers/Stakeholders

- Interoperable Foundational Data

A consideration for the visual of a fully shaded in pyramid is that would represent a completion of all levels. For a large enterprise, this takes many years in the commissioning of data alone. A phased approach means finding a way to leverage return along the migration of data.

Building a foundation

PMC Early EFI Value

Interoperable data can enable so many more value propositions than just big data forecasting. This is the reason EFI is able to phase return on investment. The iBIM goal, for example, from the UK standard, is a milestone of rich data collection that comes from construction and renovation projects. Integrated design workflows in facility construction have proven “SMARTER, CHEAPER, FASTER…” for owners, Architects, and Construction managers. The same can be said for digital factory. However, those value propositions often end in throw-away record data. That might be because they lack the higher value interoperability that facilities management (FM) and operations requires. Another possibility is that without people in stakeholder positions the data goes un-managed and becomes obsolete. A well-planned early phase should milestone for these possibilities and migrate people and data to implementation.

PMC will continue to digitize everything in our path as it has done for more than twenty five years. However, over the past several years we have made it a goal to not deliver throw-away data. The way we do that is to ask about a higher longer term value of interoperability. My team and I are also seeking to partner with our clients so that our foundational digital modeling services also deliver sustainable data. Over the last two years we have looked to consult on all barriers that prevent functional teams from operating and maintaining the data we deliver. This is why we have developed partnerships and services to compliment 3D data capture services. Here are a few we provide.

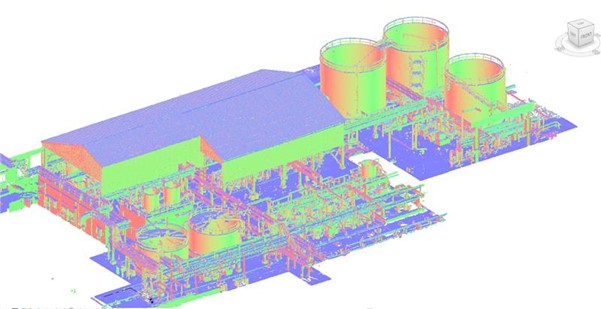

- Site and Building Reality capture at all scales of precision

- Certified Training solutions in the cloud and on-site

- Multi-site digital facility hosting

- BIM to Operations implementation and training

- VR/AR mixed ready content

- BIM/Plant3D/Part scanning

- Asset in formation Modeling

- Data standard consulting

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?