Summary

This project report outlines the steel detailing and laser scanning services provided by Production Modeling India Pvt. Ltd. (PMI) for the University of Michigan’s Central Power Plant (CPP) infrastructure upgrade. The CPP provides the university's Central and Medical Campuses with vital utilities like steam, electricity, compressed air, and hot water. The University started removing a three-story boiler, creating a significant structural gap, as part of its efforts to modernize operations and move toward a more ecologically friendly campus.

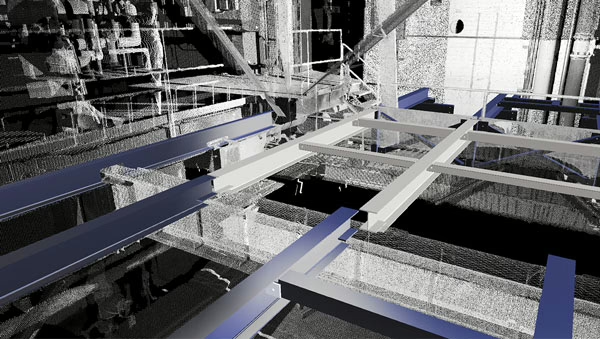

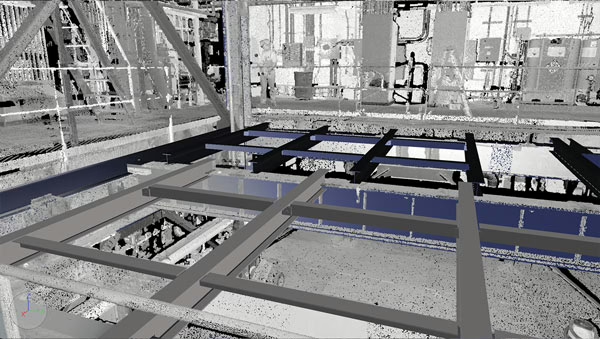

PMI was brought on board to produce the precise steel detailing required to fill this void and create a walkable, functional storage area while accommodating space for future energy systems. Leveraging FARO Laser Scanning, SDS2 detailing software, and FARO WebShare for collaborative reviews, PMI rapidly collected accurate field data and integrated it with existing design documentation.

The result was a set of steel detailing drawings tailored to actual site conditions, which helped identify design oversights early and enabled cost-saving construction adjustments. These proactive measures eliminated unnecessary demolition and avoided the need for additional labor-intensive rework, ultimately saving the project several days of construction time and considerable expense.

Project Background

The Central Power Plant (CPP) of the University of Michigan provides thermal and electrical energy to its campuses. The university has pledged to lower its carbon footprint through improvements and infrastructure modernization projects because sustainability and efficiency are becoming more and more significant components of campus operations.

An old three-story boiler that wasn't part of the University's long-term energy plan was taken offline and eventually disassembled as part of this project. A major structural opening brought about by this removal presented a challenge for both design and construction. The space left behind needed to be structurally filled, not only to restore integrity to the facility, but also to repurpose the area into walkable storage and utility space to support newer, greener energy technologies.

PMI’s role was to develop the steel detailing necessary to close this opening safely and efficiently. Given the complexity of the existing structure and incomplete legacy documentation, the solution required modern scanning technologies and real-time coordination to deliver as-built accuracy and ensure structural feasibility without incurring project delays.

Objectives

The primary objective of the project was to deliver accurate and constructible steel detailing drawings to support the University of Michigan’s infrastructure enhancement at the Central Power Plant. Specifically, the project aimed to:

- Fill the structural void left by the removal of the three-story boiler using new steel flooring systems.

- Enable creation of walkable and usable storage space within the facility.

- Support the integration of future energy systems into the updated plant layout.

- Utilize laser scanning and SDS2 software to match steel detailing with actual as-built conditions.

- Identify and resolve design document mismatches before construction begins.

- Prevent construction inefficiencies and demolition mistakes to save time and money.

Digital modeling, high-resolution laser scanning, and stakeholder-initiated collaborative data reviews were used to achieve these goals.

Steel Detailing and As-Built Validation for University of Michigan’s Central Power Plant Upgrade

Challenges Identified

If not proactively addressed, a number of significant obstacles that PMI faced during the preliminary planning and analysis stage could have caused construction delays and cost increases.

Methodology

The simulation study was executed using a structured six-stage methodology developed by Production Modeling India Pvt. Ltd. (PMI). This approach ensures thorough data validation, systematic model development, and actionable insights for the client.

Step 1: On-Site Laser Scanning

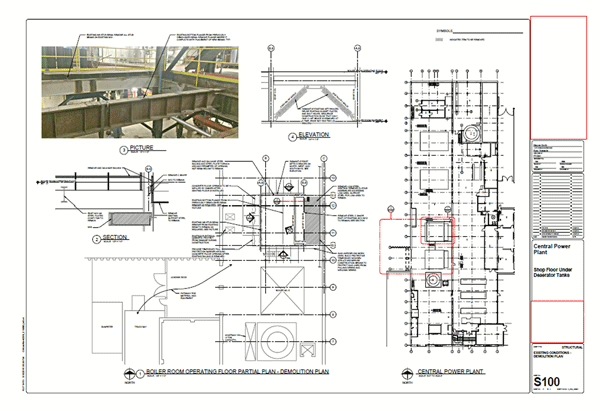

PMI team member Chris Mounts conducted a rapid site assessment using a FARO Laser Scanner. Within just 15 minutes, three full scans of the structural void were captured. These scans produced a detailed point cloud model of the site, including critical elements like: • Beam flanges • Wall surfaces • Staircases • Remaining utility lines and brackets This point cloud offered sub-millimeter accuracy and formed the foundation for subsequent detailing work.

Step 2: Data Integration with SDS2 and WebShare

After being imported into SDS2, a specialized steel detailing program, the point cloud data was compared to pre-existing engineering and demolition drawings. At the same time, PMI enabled stakeholders to remotely view the as-built site in three dimensions using FARO WebShare, a cloud-based collaboration tool. The detailing team was able to validate assumptions, resolve ambiguities, and suggest workable design modifications without the need for extra site visits or interruptions thanks to this real-time visualization.

Step 3: Iterative Design Refinement

PMI then aligned the steel detailing model with the actual geometry of the site, enabling accurate beam placement, clash avoidance, and optimized framing adjustments, all supported by measured data rather than field estimations.

Solution Implementation

The accurate point cloud data captured during scanning revealed several opportunities to refine the steel detailing and reduce project scope complexity.

Avoiding Millwright Work

The original construction plan included grinding abandoned steel plates on beam flanges, a task typically requiring specialized millwright labor. However, the laser scans showed sufficient clearance to reposition the beams, effectively eliminating the need to remove the plates. This change:

• Reduced labor costs

• Accelerated installation

• Avoided disruption to existing structural members

Adjusting for Obstructions

The scan identified a damaged concrete surface and a problematic L-bracket that would have required significant demolition if followed by the original design. Instead of removing these components, PMI proposed raising the floor framing by 4 inches, allowing the new beams to bypass the obstructions entirely.

This small vertical adjustment provided a substantial benefit by:

• Preserving the structural integrity of nearby features

• Preventing unnecessary demolition work

• Maintaining the desired functional height for storage use

Preserving the Staircase

One of the more impactful discoveries was that the existing staircase near the structural void did not require removal. Using spatial analysis from the scan, PMI adjusted the framing layout to accommodate the staircase without physical modification. This decision preserved access, saved demolition time, and avoided rebuilding expenses.

These field-informed modifications were directly incorporated into the SDS2 model and finalized in the detailing package submitted to the University.

Key Results & Impact

The integration of 3D laser scanning and intelligent detailing produced measurable benefits for the University of Michigan project in terms of cost, schedule, and constructibility.

Cost Savings

Design Accuracy

Time Savings

Construction Efficiency

All things considered, the project serves as a template for contemporary infrastructure improvements that place an emphasis on digital accuracy and teamwork.

Conclusion

One example of the transformative potential of fusing 3D laser scanning with intricate steel detailing is the Central Power Plant project at the University of Michigan. Using tools like FARO Laser Scanner, SDS2, and WebShare, PMI was able to provide a very accurate and cost-effective detailing solution that considered actual site conditions and decreased construction risks.

Measureable time, labor, and material savings resulted from proactive design modifications like obstruction avoidance, elevation changes, and beam repositioning. More significantly, this strategy boosted stakeholder trust and advanced the university's larger modernization and sustainability objectives.

The success of this project reaffirms PMI’s commitment to delivering smart, field-validated detailing for complex infrastructure environments.