MODAPTS Study for a Major Automotive Supplier OEM

A third-party supplier manufactures plastic automotive interior components for various automotive customers. The facility where this project was conducted comprises injection molding components, painting components and assembling part and sub-assemblies.

The objective of this study was to calculate operator efficiency for automotive and to categorize operator utilization as under-utilized, efficiently utilized or over-utilized/worked.

SYSTEM DESCRIPTION

This facility operates three processes – plastics injection molding, painting of molded parts and assembly comprising of several parts and/or assemblies. The processes are split into various work stations.

Molding contains fifty-six different presses with tooling molds numbering three hundred and fifteen. Personnel allocation is one operator per press; in cases of slower production rates, a single operator manages two presses. A press operator’s responsibilities include packaging newly molded plastics into appropriate containers, processing those containers with the corresponding inventory labeling and readying containers of molded parts for placement in inventory by the logistics operators.

There are two separate lines for painting, considered as Paint Line 1 and Paint Line 2. Paint Line 1 is the larger of the two lines, in terms of the number of operators involved at the line. The painting line consists of six distinct processes or stages: loading of unpainted parts onto appropriate racks, wiping of loaded parts, unloading of painted parts, inspection of unloaded parts and packing of inspected parts; labeling of filled containers is a separate process that is independent from the paint lines (each paint line is independent from each other).

Assembly comprises over a hundred stations, each responsible for the assembling of a specific component or a sub-assembly. Each station has a personnel allocation of a single operator. A “spider” operator handles the labeling and container processes for several stations.

OPPORTUNITY

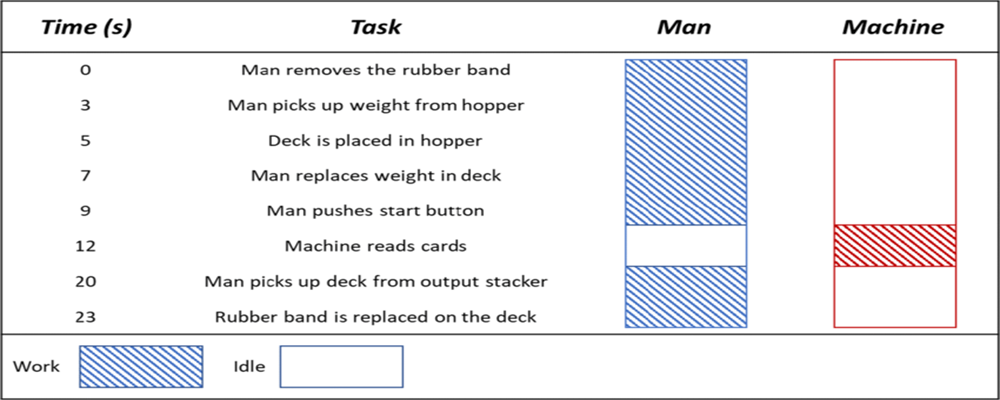

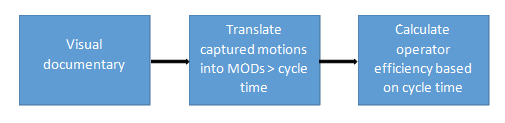

Since the focus was on operator efficiency, MODAPTS (Modular Arrangement of Predetermined Time Standards) was considered the most feasible approach. By assigning predetermined time standards to each of the captured operator’s motions for each station, a concrete cycle time without any non-value added activities can be determined.

APPROACH

The first phase consisted of videotaping each operator as they conducted their work, with emphasis on their motions. The second phase was to translate the captured motions into MODS or predetermined time standards – a total time to complete a set of motions without the presence of any non-value added activities. The third and final phase was to input the produced results into a proprietary process book.

SOLUTION

After translating the captured motions into MODs, operational cycle time was determined by inputting the MODs into a proprietary Microsoft Excel process book. This process book takes the MOD values and translates them into a calculated time based upon predetermined standards. Then, based on the operational cycle time, along with a variable production cycle rate, daily production volume and production length (i.e. number of shifts per day or number of days per week, etc.), an operator’s efficiency was derived for a particular station. The calculated efficiency was then categorized into three distinct categories – the operator of a particular station was determined to be either under-utilized, optimally utilized or over-utilized.

BENEFIT

Having determined an operator’s potential efficiency for any particular [assembly, painting operation, press and tooling] station based on an ideal cycle time and other dependent variables, personnel allocation can be forecasted more precisely. An operator with low utilization at a particular station could be otherwise used as an additional resource for another low utilization station. Likewise, a station that produces a utilization that is determined to be high [over-utilized] can be alleviated by adding an additional operator, thus distributing the high utilization of a single operator into two [or more] operators.

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?

Recent posts