Introduction

Launching a greenfield facility comes with a blend of ambition and uncertainty. For a leading industrial manufacturer setting up a new plant with batch-type production involving 14 distinct product types, forecasting throughput wasn’t straightforward. Each product came with its own process flow and cycle time, making system behavior hard to predict.

The client needed clarity: Could the facility meet its expected production targets under real operating conditions? That’s when Production Modeling India (PMI) stepped in to help validate and improve the plant's design and operational strategy.

Client’s Challenge

• Cycle times varied significantly across products, complicating scheduling.

• Batch sizes differed at each stage of the production flow.

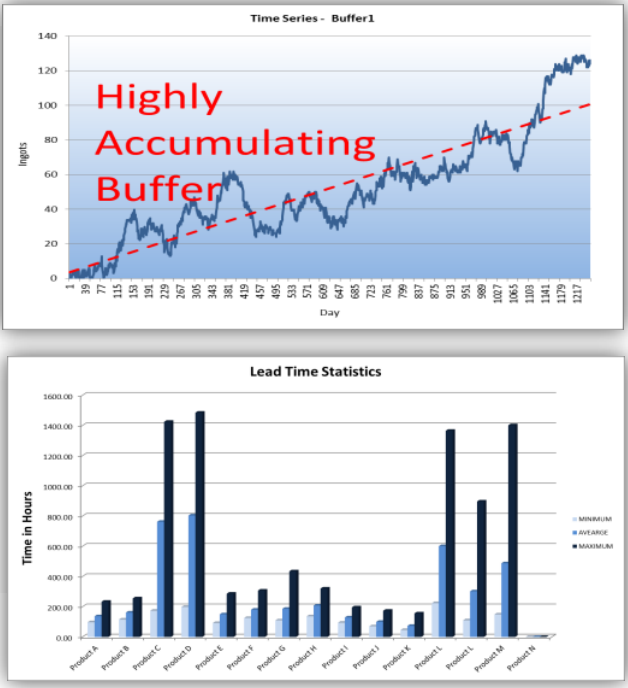

• Buffer requirements were difficult to determine with high product mix variability.

• The facility risked underperforming against throughput targets without accurate modeling.

How PMI Increased Throughput by 18% Through Product Mix Optimization and Buffer Strategy in a Greenfield Facility

PMI’s Approach

To address these complexities, PMI used a simulation-driven approach:

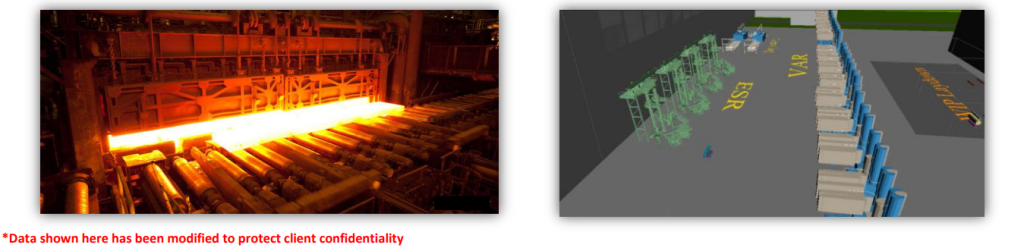

Built a comprehensive 3D simulation model of the entire plant, capturing equipment behavior, flow rules, and product dependencies.

Simulated different product mix combinations to understand their effect on overall system throughput.

Based on simulation outcomes, a throughput improvement roadmap was developed to align operations with business targets.

Findings and Recommendations

• The existing setup was underperforming, delivering 18% less throughput than expected.

• Product mix had a major influence on flow—certain sequences severely affected resource utilization.

• Required buffer capacities were calculated to absorb variability in flow and reduce starvation/blockage.

• The number of resources (machines and operators) needed to meet the expected demand was determined.

• The average lead time was calculated, helping the client establish realistic delivery benchmarks.

Conclusion

PMI’s strategic simulation uncovered hidden performance constraints and equipped the client with actionable data. With a clear throughput improvement roadmap, the greenfield facility now had the tools to evolve from uncertainty to controlled, scalable growth.