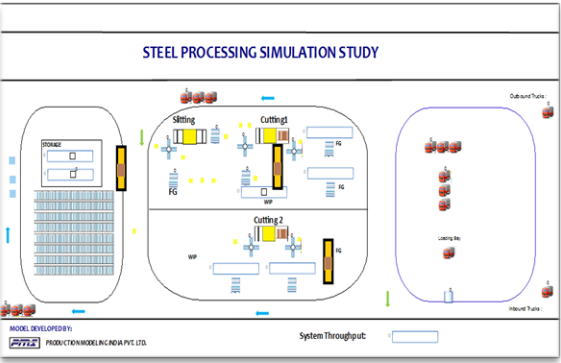

Study for Validating the Plan of a New Steel Processing Plant Setup

STEEL INDUSTRYCapacity Validation Study

Study for Validating the Plan of a New Steel Processing Plant Setup

Key Points

- Storage space requirement

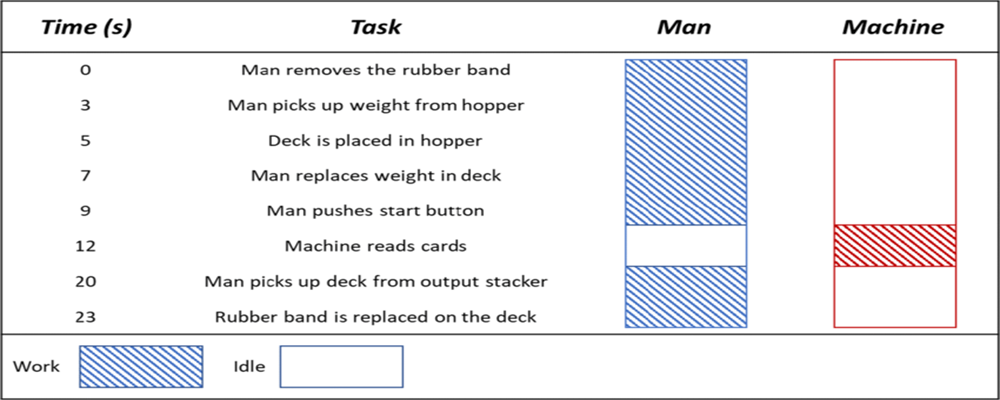

- MHE utilization observation (for cranes and forklifts)

- Dispatch truck utilization improvement

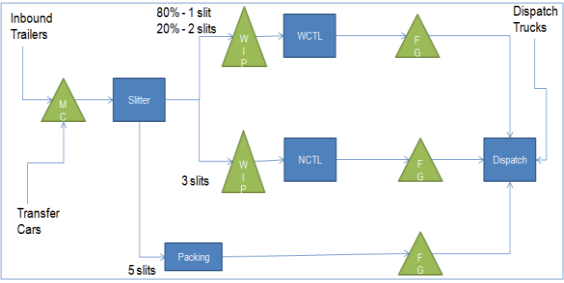

Client's Challenge

- There exist certain constraints in the existing setup

- The new proposed facility to be free of these constraints

- Calculation on the number of cranes, and MHEs required

- Calculation of storage space

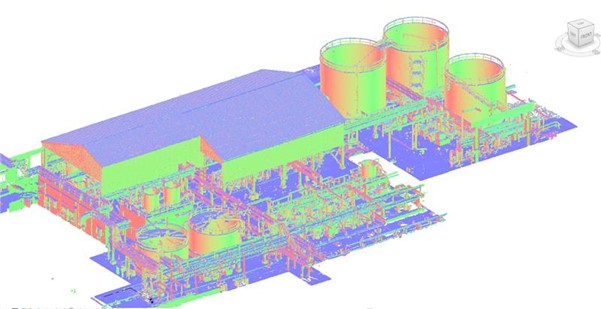

PMI's Approach

- Analysis of Data, building the model, and verification

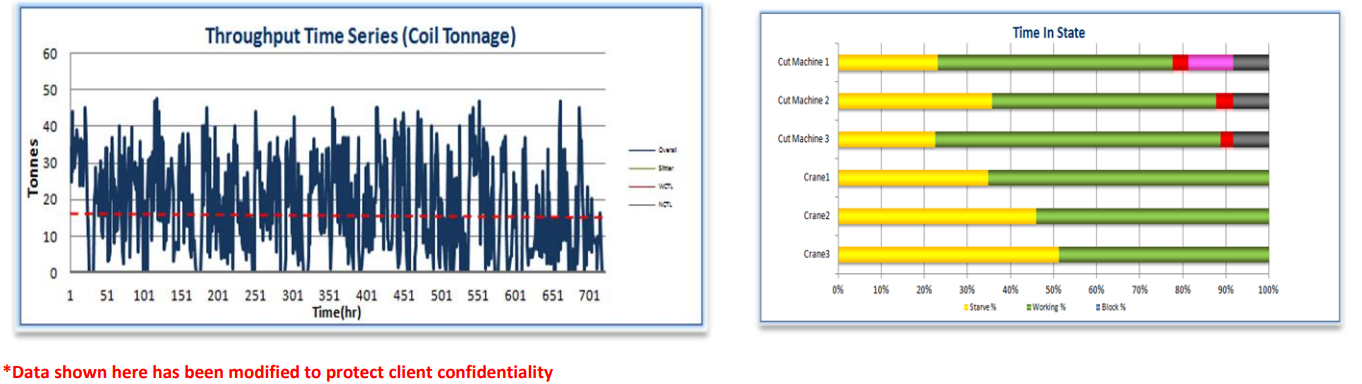

- Analysis of baseline model results

- Bottleneck identification

- Debottlenecking

- Storage space reallocation based on iterative analysis

Findings & Recommendation

- Plant capacity (of 21 tonnes/hr) validated

- Present number of cranes was found insufficient

- Hence some material handling was shifted to a forklift to

reduce the load on the crane - Optimum truck inter-arrival time determined

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?