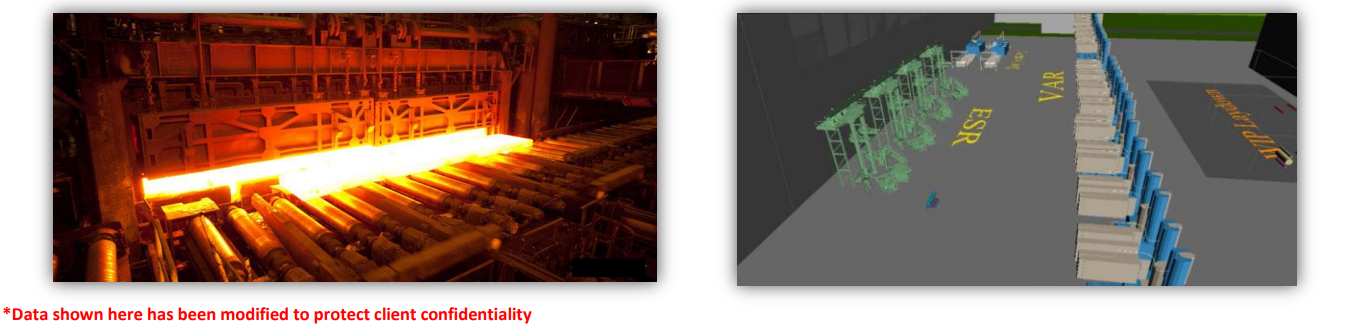

Greenfield Facility – Throughput Validation and Improvement

STEEL INDUSTRYGreenfieldThroughput Validation

Greenfield Facility - Throughput Validation and Improvement

Key Points

- Batch type production - 14 Product Types

- Impact of Product Mix on system throughput

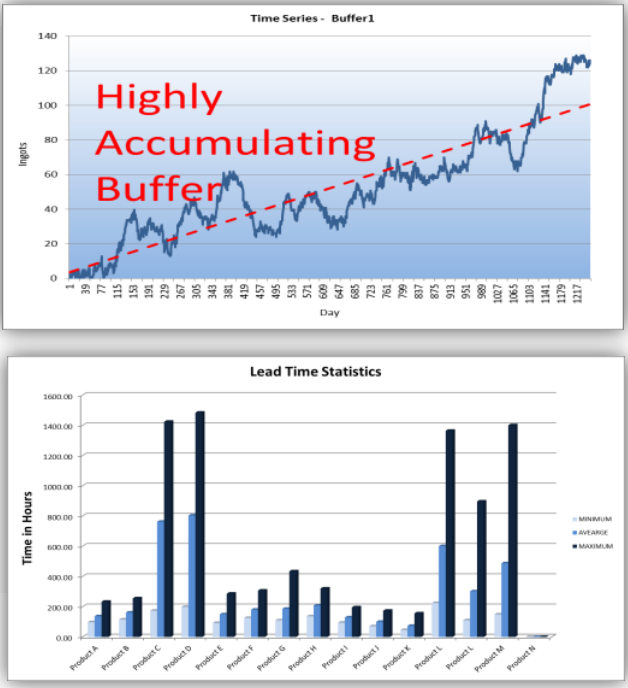

- Buffer sensitivity analysis

Client's Challenge

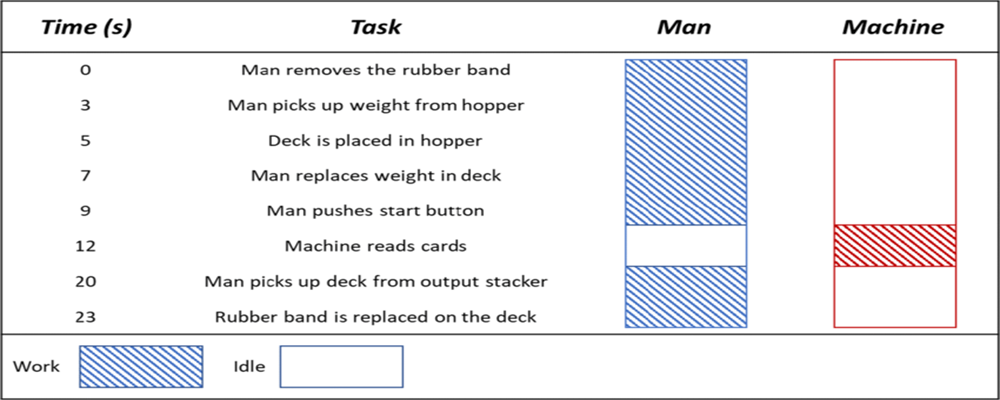

- 14 Product types with different foundry flow and product-dependent cycle

time made it difficult to calculate the system's throughput - Equipment Utilization was highly dependent on Product Mix

- Batch size of a product family - Different across the process flow

- With all the above variations, predicting the required buffer capacities

PMI's Approach

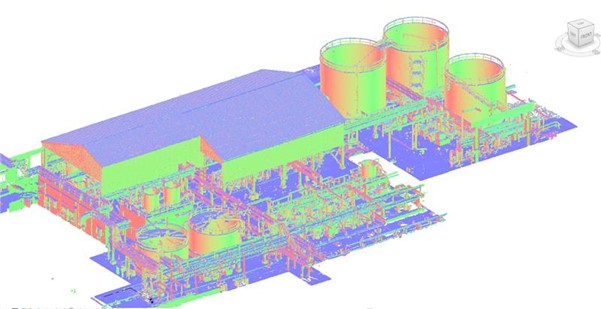

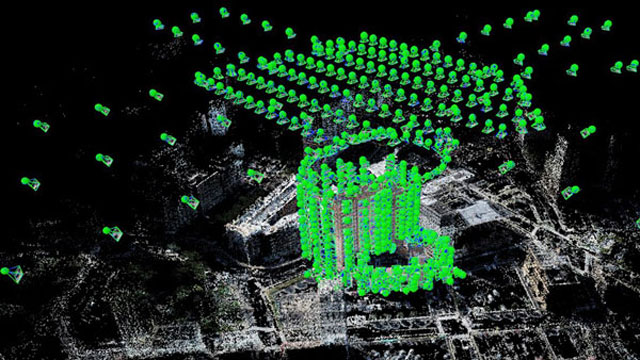

- Data analysis, 3D model building, verification & validation

- Throughput improvement carried out by analysis of product mix

- Sensitivity Analysis carried out on buffer capacity

- The throughput Improvement Roadmap was built to meet the expected demand

- Sensitivity Analysis also carried out on buffer capacity for expected demand

Findings & Recommendation

- The facility was unable to meet the target throughput

- Throughput showed strong dependence on Product Mix

- With the current setup, max. system throughput was validated to be 18% less than expected

- The number of resources required to satisfy expected demand was calculated

- Required buffer capacities around the facility were suggested

- The average lead time was indicated

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?