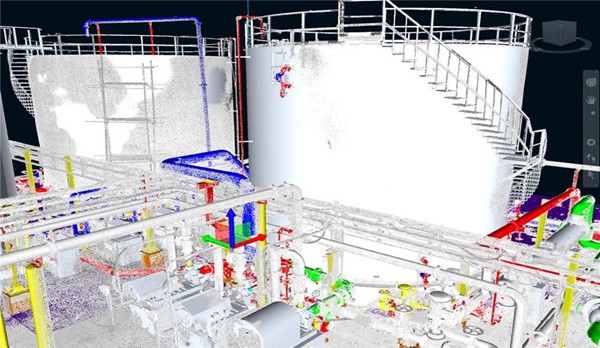

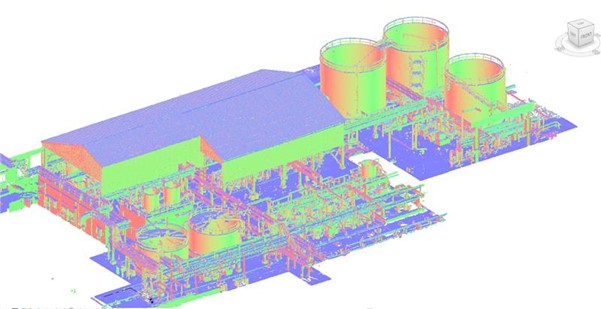

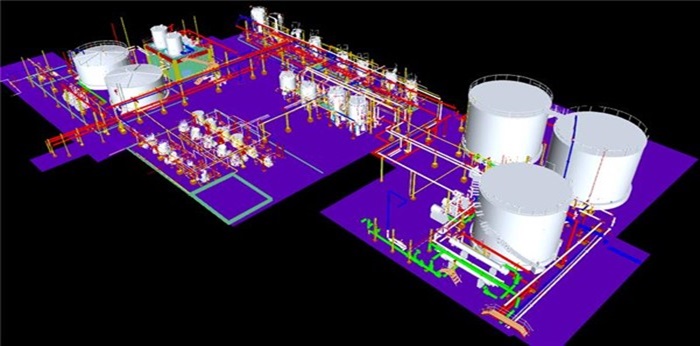

Optimizing Plant Expansion: 3D Laser Scanning and Modeling for the Gas Industry

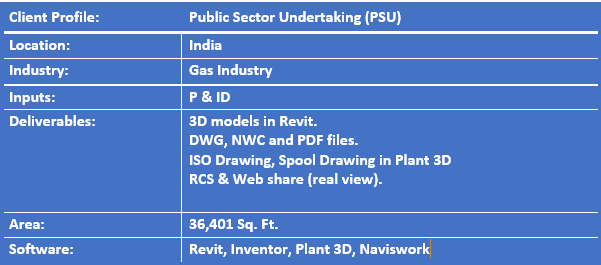

Project Details:

Business Needs:

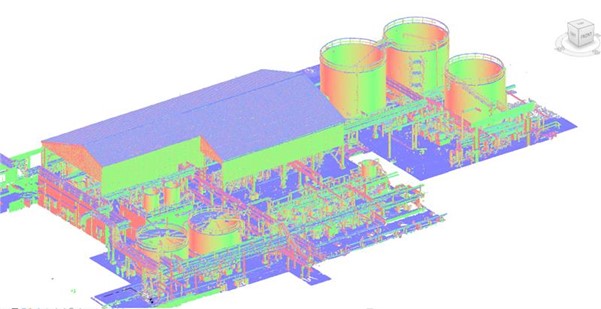

- 3D laser scanning of the existing plant to expansion and modification of Plant.

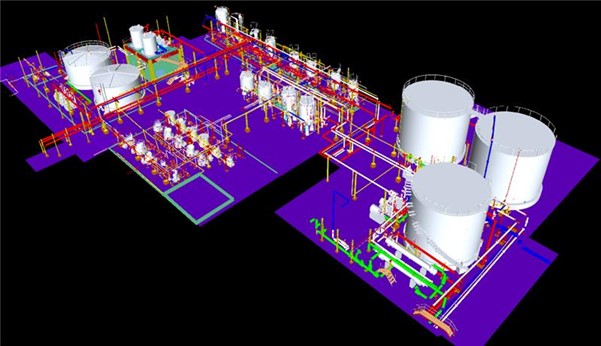

- 3D Scanned data further used to create as built drawings

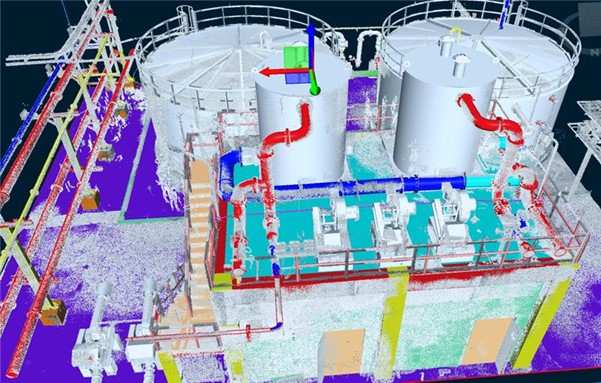

- Accurate documentation and visualization

- To plan and design, expansions, or modifications in the process

Challenges:

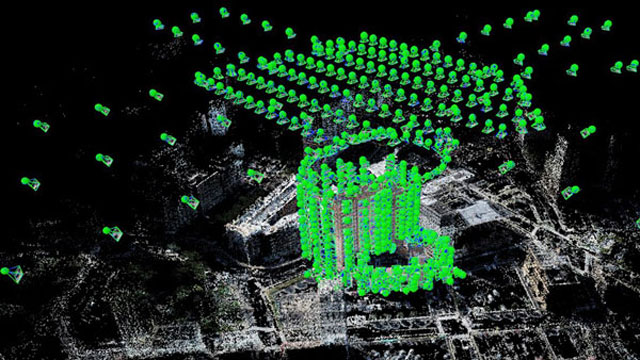

- Managing and coordinating the scanning process for such a large area could be challenging and accurate scanning and proper registration of 565 scans can be technically demanding

- Processing and cleaning the large volume of scan data to prepare it for modelling can be time-consuming.

- Modeling pipes and piping accessories accurately based on scanned data requires expertise in CAD software (such as Revit or AutoCAD). accurately represent pipe diameters, fittings, Flange, valves, and other accessories.

- Exporting ISO drawings, Spool Drawing from the 3D model involves translating the digital model into detailed engineering drawings

- Effective communication and coordination with various stakeholders (engineers, designers, project managers) throughout the scanning, modelling, and drawing production phases are essential.

- Managing the project timeline to meet deadlines while ensuring quality standards can be demanding

Our Solutions & Approach:

- Create a detailed scanning plan with clear milestones and objectives for each section. Allocate sufficient time and resources for each phase of scanning to ensure thorough coverage.

- Utilize high-precision 3D laser scanners capable of capturing detailed data with minimal error. Implement stringent quality control measures during scanning to ensure each scan is accurately registered and aligned.

- Engage experienced CAD modelers proficient in software like Revit or AutoCAD. Ensure they have a comprehensive understanding of piping systems and engineering standards.

- Utilize software tools that support ISO drawing generation from 3D models. Ensure all required details, including dimensions, annotations, symbols, and material specifications, are accurately represented.

- Implement rigorous quality assurance protocols, including clash detection and dimensional checks, throughout the modeling and drawing production phases.

- Develop a detailed project schedule with realistic milestones and deadlines. Allocate resources effectively to meet project timelines without compromising quality.

Business Impact:

- Successfully implementing 3D laser scanning, modeling, and ISO drawing generation for the Demineralization Plant retrofit project includes enhanced operational efficiency, reduced construction costs through minimized rework, and improved facility management.

- The ability to visualize and manage plant infrastructure effectively supports maintenance scheduling and upgrades, optimizing overall asset performance and extending the lifespan of critical equipment.

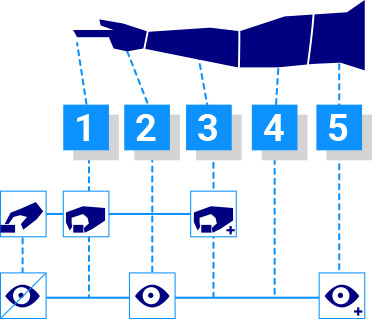

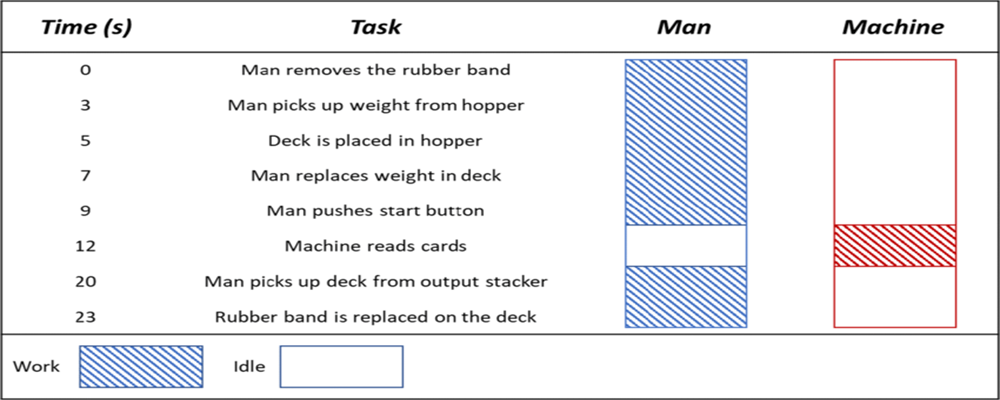

Workflow for 3D Laser Scanning and Data Processing:

- Preparation Phase

- Scanning Phase

- Data Processing Phase

- Modeling Phase

- ISO Drawing Generation Phase

- Documentation and Reporting

- Post-Project Evaluation

MODEL THAT WE SUBMITTED ACCURATLY REPRESENTS THE PROJECT DETAILS DESIGN AND SPECIFICATIONS.

Recent posts