Introduction

In any industrial setup, indirect areas such as sanitation, machine cleaning, security, and R&D often operate in the background—quietly essential yet frequently overlooked. A leading manufacturing firm recognized that these functions, though not directly linked to production, had a significant impact on efficiency, cost, and operational discipline. The organization sought clarity on how these departments could be optimized through structured manpower deployment and accurate work content estimation.

With this goal, the company partnered with Production Modeling India (PMI) to study indirect departments and identify opportunities for resource optimization through industrial engineering tools.

Client’s Challenge

• Overstaffing concerns in departments like housekeeping and security

• Need for transparent manpower benchmarks to support cost rationalization

• Desire to identify non-value-added activities and streamline repetitive processes

PMI’s Approach

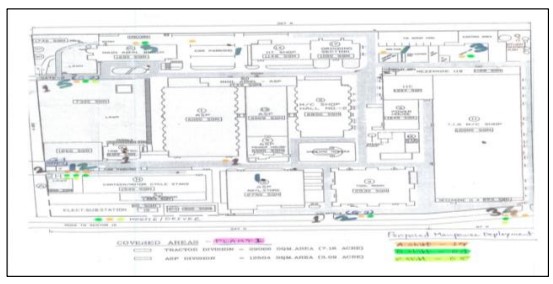

PMI employed a methodical process across multiple departments including Machine Cleaning, Housekeeping/Sanitation, Horticulture, Security, and R&D. The approach included:

- Designing customized data collection formats.

- Conducting video time studies and work sampling for each area.

- Analyzing activities based on VA (Value Added), NVA (Non-Value Added), and SVA (Supportive Value Added) frameworks.

- Creating a Master Activity Sheet to serve as a dynamic tool for manpower planning and task redistribution.

Key Outcomes

By combining time-motion studies with work analysis, PMI delivered measurable results:

These optimizations were not only cost-effective but also aligned teams more closely with their core functions, reducing redundancy and enhancing accountability.

Conclusion

PMI’s structured study empowered the client with data-backed insights to optimize manpower, boost productivity, and bring discipline into indirect areas. It was a quiet transformation—but one with powerful results.