Introduction

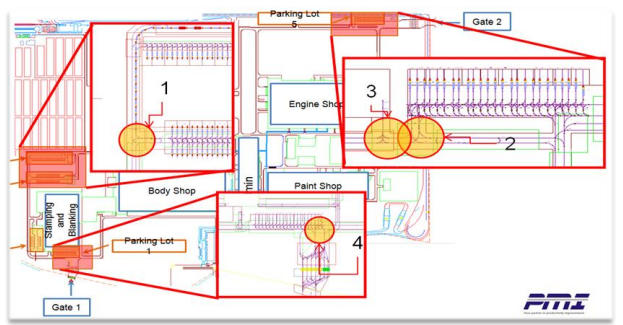

In large-scale manufacturing plants, particularly in the automobile sector, internal truck and personal transport are critical in maintaining smooth operations. At a newly developed greenfield plant, one of the industry's top manufacturers discovered that even with contemporary infrastructure, congestion at gates, docks, and shop shutters was causing delivery delays and production clogs.

To address this challenge proactively, the company partnered with Production Modeling India (PMI) to conduct a detailed traffic congestion analysis within the plant premises.

Client’s Challenge

• Predict and prevent congestion around unloading zones, especially at the TCF (Trim, Chassis, Final) shutter area.

• Evaluate if existing parking and dock arrangements would be sufficient for peak volumes.

• Integrate in-plant and canteen shuttle schedules without interrupting truck flow.

• Minimize truck lead time from arrival to unloading.

Optimizing Truck Flow and Parking in Automotive Manufacturing Plant Using Simulation - A Case Study

PMI’s Approach

PMI began by creating a baseline simulation model to analyze vehicle movements, dock usage, and queue behavior. The methodology included:

Real-world inputs were gathered on vehicle arrivals, loading/unloading times, shuttle movement, and dock schedules.

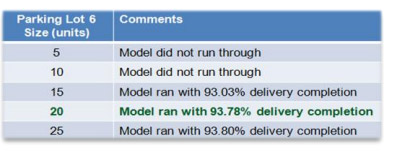

A deep-dive study into available parking spaces revealed insufficiencies in accommodating peak truck arrivals.

Detailed observation at the TCF area showed frequent delays, prompting further study of unloading cycles and shutter availability.

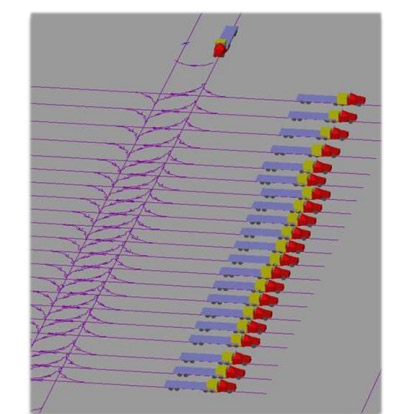

PMI tested different configurations such as number of shutters, parking allocations, and dedicated vehicle routes.

Findings & Recommendations

• Parking capacity needed to be increased by 20 trucks to handle demand without creating queues.

• Unloading time at TCF shutters should be maintained under 15 minutes to avoid cascading delays.

• Signaling systems at shutter areas were recommended to reduce idle wait times

• A dedicated vehicle route for TCF-bound trucks was proposed to prevent cross-path conflicts.

• Prioritized parking slots near active docks would help minimize truck lead times.

• Adjustments to shuttle schedules ensured smoother people movement without conflicting with goods traffic

Conclusion

logistics efficiency, setting a strong foundation for smooth plant operations.