Precision and Efficiency: Enhance Your Manufacturing Process with Custom Jigs and Fixtures

Jig and fixture design involves creating specialized equipment to securely hold and align components during manufacturing operations such as milling, drilling, and welding. Jigs provide guidance for cutting tools, while fixtures ensure the workpiece is securely held in place. These tools are tailored to specific parts and processes, aiming to enhance precision, minimize setup time, and improve overall efficiency.

Our team of skilled engineers and designers collaborate closely with clients to gain a deep understanding of their specific requirements. We then develop tailor-made solutions that optimize operations and drive cost savings. Leveraging state-of-the-art 3D modeling software, we swiftly generate prototypes for thorough testing and evaluation prior to final production.

Jig and Fixture Design Capabilities

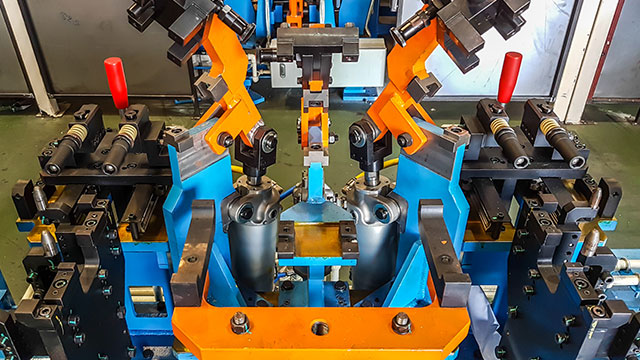

Body in White Manufacturing Tool and Fixture Design

Body in White (BIW) refers to the stage in automotive production when sheet metal components are joined together by welding. Jigs and fixtures are utilized to guarantee the precise alignment of all components.

PMI specializes in designing tools and fixtures for the automotive industry, with a focus on enhancing productivity and efficiency.

Welding Fixture Design

By utilizing welding fixture design, manufacturers can enhance efficiency, accuracy, quality, and safety, while minimizing costs and achieving consistency in the welding process.

We work closely with our clients to design welding fixtures that meet specific requirements and identify any issues during the design phase, allowing for early error detection and resolution.

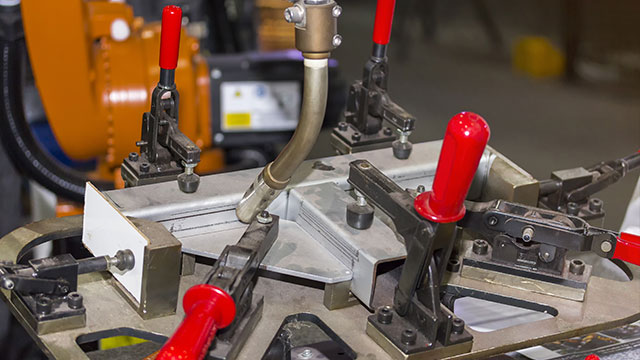

General Assembly Tool and Fixture Design

Customized tool and fixture designs for general assembly processes can boost precision, speed, and consistency, leading to higher quality products with a minimized risk of errors and improved productivity.

With the aid of cutting-edge rendering software, our expert teams can tailor tools and fixtures to meet your specific requirements and specifications.

Our Jig and Fixture Design Benefits

- Tailored designs: We customize our jigs and fixtures to meet the unique needs of your manufacturing process or product.

- Design Support for Change Management: PMI provides comprehensive design support, including assistance with change notices, modifications, engineering changes, drawing changes, and CAD-level modifications. We can also assist with the bill of materials and layout of pneumatic drawings.

- Safety-oriented design: Our jigs and fixtures are designed with safety in mind. We follow relevant safety regulations and standards to minimize the risk of injuries during the manufacturing process.

- ISO and ISMS certification: Our commitment to quality is reflected in our ISO 9001-2015 (QMS) and ISMS 27001-2013 certifications. These international standards ensure that our jigs and fixtures are designed and constructed according to a consistent, reliable process, assuring our customers.

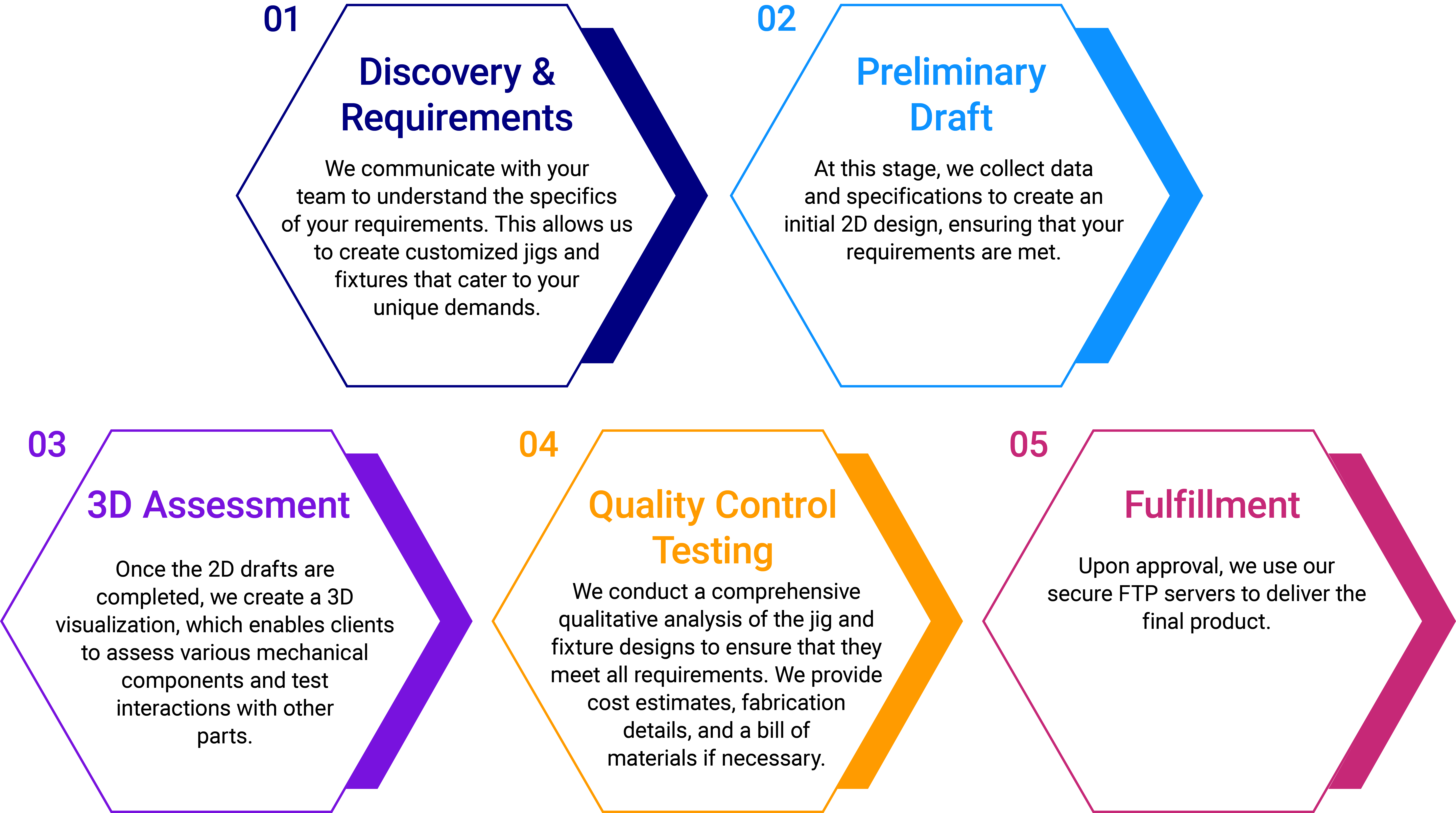

Our Jig and Fixture Design Process

- Discovery & Requirements

We communicate with your team to understand the specifics of your requirements. This allows us to create customized jigs and fixtures that cater to your unique demands. - Preliminary Draft

At this stage, we collect data and specifications to create an initial 2D design, ensuring that your requirements are met. - 3D Assessment

Once the 2D drafts are completed, we create a 3D visualization, which enables clients to assess various mechanical components and test interactions with other parts. - Quality Control Testing

We conduct a comprehensive qualitative analysis of the jig and fixture designs to ensure that they meet all requirements. We provide cost estimates, fabrication details, and a bill of materials if necessary. - Fulfillment

Upon approval, we use our secure FTP servers to deliver the final product.

Software & Technologies

PMC has in-depth experience with a variety of common software options that are used in tool and fixture design. Software utilization will vary on specific client needs, industry preference, and the company preference.

Production of Jig and Fixture Hardware

We provide design services for these crucial jigs that enhance manufacturing efficiency and guarantee quality standards. Alongside our design capabilities, we facilitate jig and fixture builds. Our team collaborates closely with clients to understand their specific requirements and oversee the fabrication and assembly of jigs and fixtures, ensuring they meet your necessary specifications. Our end-to-end approach ensures that clients receive a comprehensive solution to meet their needs.

Market Areas

- Aerospace Manufacturing Jig and Fixtures

- Automotive and BIW Jig and Fixtures

- Consumer Product Jig and Fixtures

- Industrial Manufacturing Jig and Fixtures

Experienced jig and fixture specialists play a critical role in ensuring optimal design and construction, resulting in improved efficiency, precision, and compliance with safety regulations. This leads to increased productivity, reduced costs, and high-quality end products across various industries. Jig and fixture design offers numerous benefits, including improved efficiency and precision in component assembly, better utilization of production space, and compliance with safety regulations and standards. These advantages contribute to increased productivity, reduced costs, and the delivery of high-quality end products.

Why Choose PMI

PMI offers competitive pricing as a cost-effective and quality solution provider. Our engineers and designers have over 30 years of experience and deep industry knowledge, providing confidence in customized design solutions that increase efficiency and reduce costs. We strictly comply with regional safety regulations and standards to encourage a safe manufacturing process, and our rigorous quality assurance guarantees that the final product meets all client requirements and specifications.

Related Service: Industrial Engineering with Simulation Services

In industrial engineering, simulation is used to analyze and evaluate spaces in terms of performance, dimensions, throughput times, capacities, staffing requirements, and other planning parameters. The visual representation capabilities of simulation also make it possible to compare different scenarios for a space and evaluate their effectiveness.

PMI offers simulation services to a wide range of clients, including warehouses, manufacturing plants, and automotive companies. The ability to test processes and explore "what-if" scenarios before implementation can help prevent costly mistakes and aid in making informed decisions.

Frequently Asked Questions for Jigs and Fixtures

Speak with one of our Jig and Fixture Design Experts!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?