Unlock hidden insights and transform data into action with Discrete Event Simulation

- DES is a computational modeling technique that involves the modeling of a series of events that occur at discrete points in time

- DES is used to simulate and analyze complex systems to gain comprehensive understanding of systems and the interactions between different elements, allowing businesses to make informed decisions based on a range of scenarios

Why Use Discrete Event Simulation?

- Data-driven approach: Transform complex systems into clear data driven solutions

- Reduce risk: Mitigate unexpected consequences and costly mistakes before implementation

- Optimize resources: Allocate resources such as manpower, materials, and equipment, to increase efficiency and cost savings.

- Improve understanding: Accurately represent the real-world behavior of systems, providing valuable insights and predictions

- Make informed decisions: Evaluate different design options, operational strategies, and policy decisions

Industries that Benefit from Discrete Event Simulation

Automotive

Manufacturing

Warehouse and Logistics

Healthcare

Food and Beverage

Pharmaceutical

Banking

Restaurants

Why PMI?

- One-stop solution for industrial engineering & simulation needs

- Global industrial exposure spread across India, USA, Mexico, Brazil, China, Thailand, and Europe.

- Team of domain experts and trained professionals

- Proven track record: Successfully completed 1000+ projects

PMI Discrete Event Advantages & Benefits

Our experts don’t just build models, we build active, performing systems.

- Adapt quickly to growing and fluctuating demand

- Evaluate system readiness for new product introduction

- Quantify impact of operational uncertainties such as downtimes

- Analyze proposals for facility growth

- Validate operational rules

- Overcome frequent material shortages & line stoppages

- Provide insights to increase ROI

Our Experts

With over 30 years of experience with simulation technology and software, PMI brings knowledge and experience to your project. We employ highly experienced team members who possess a wealth of knowledge in multiple industries. Let our qualified specialists help meet your needs!

Software & Technologies

Related Service: Industrial Engineering with Simulation Services

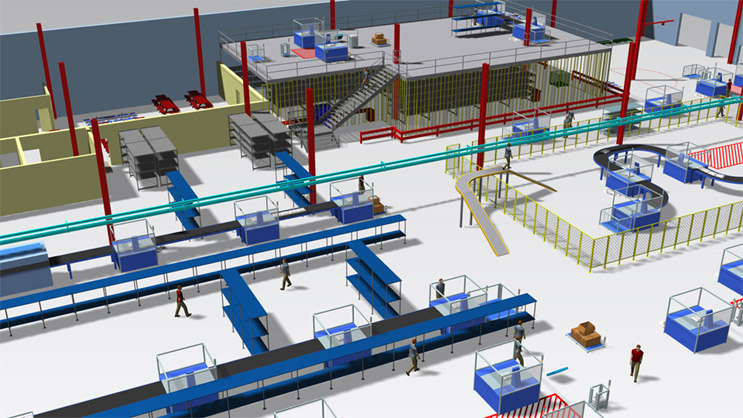

In industrial engineering, simulation is used to analyze and evaluate spaces in terms of performance, dimensions, throughput times, capacities, staffing requirements, and other planning parameters. The visual representation capabilities of simulation also make it possible to compare different scenarios for a space and evaluate their effectiveness.

PMI offers simulation services to a wide range of clients, including warehouses, manufacturing plants, and automotive companies. The ability to test processes and explore "what-if" scenarios before implementation can help prevent costly mistakes and aid in making informed decisions.

Frequently Asked Questions for Discrete Event Simulation

Discrete Event Media

Let our experts show you how our Discrete Event Simulation Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?