Enhance your processes for a competitive edge: Layout & Material Flow can help.

When planning layouts and material flow with proper understanding, approach, and experience, you can significantly impact overall manufacturing productivity.

Efficient layouts and material flow allow a facility to function at its highest potential, which translates to increased productivity, time, and quality benefits. With PMI as a layout and material flow consulting partner, highly functional plant operations are within reach.

Our Layout & Material Flow Services Include

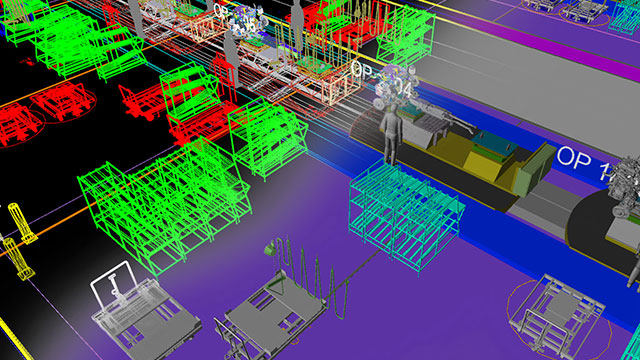

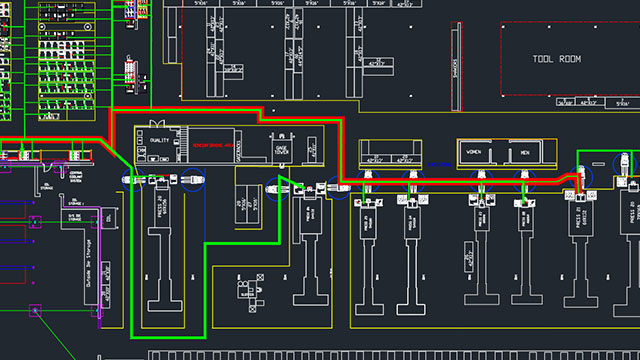

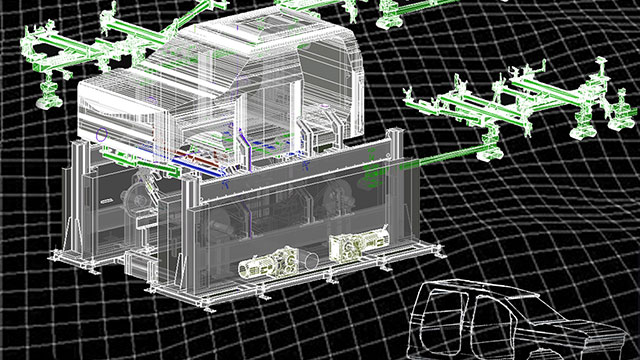

Factory Layout Design & Optimization Services

PMI offers expert factory layout design and optimization services with over 30 years of experience. Their team of experts can help improve production processes by selecting the best techniques for a specific problem and industry, and providing optimization recommendations and reports. PMI helps clients streamline their material flow and increase efficiency.

Lean Concept MUDA Reduction

Lean concept MUDA reduction services aim to eliminate waste and optimize processes for increased efficiency, resulting in cost savings and improved productivity. The services focus on identifying and removing non-value-adding activities (MUDA) in the production process.

Supply Chain Optimization

Our objective is to streamline and improve the efficiency of your company's supply chain operations. Our team of experts analyze your current processes and provide recommendations to reduce waste, lower costs, and increase overall performance. Through process improvement, logistics optimization, or inventory management, PMI can help optimize your supply chain to drive success.

Plan for Every Part Manufacturing Consulting

PFEP stands for Plan For Every Part. It is a process of defining and organizing information related to every part of a manufacturing system. It provides a structured approach for tracking part data, such as inventory levels, supplier information, production processes, and packaging requirements. The purpose of PFEP is to streamline the entire supply chain and improve the efficiency of the manufacturing process.

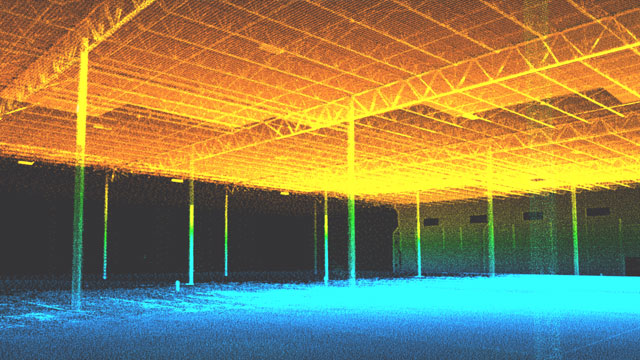

Warehouse Layout Design Services

Our expert warehousing layout design services optimize space utilization, improve material flow, and enhance overall efficiency. By implementing PMI's warehousing layout design services, clients can increase productivity, reduce costs, and improve the overall effectiveness of their warehouse operations.

Warehouse Operations Support

We support and inform warehouse operations management and coordination of activities and processes with the objective of ensuring the efficient and accurate movement of goods, reducing costs, and improving customer satisfaction. This includes optimization of activities such as receiving and storing goods, organizing and maintaining inventory, and preparing and shipping outbound orders.

Material Flow Simulation Services

PMI's simulation capabilities analyze the movement of materials through a warehouse or manufacturing facility to optimize efficiency and productivity. Our service uses modeling techniques to predict and visualize how materials move through a system, identify bottlenecks, and evaluate potential solutions to improve material flow. Our goal is to help organizations make informed decisions about their material handling operations and improve overall performance.

Material Handling Consulting Services

Our material handling consulting services help companies streamline and optimize their material handling processes for improved efficiency, cost-effectiveness, and safety. Whether it is optimizing existing processes or designing new ones, our goal is to help you achieve your production goals by providing customized and practical solutions.

Ergonomics Assessment + Material Handling

Our ergonomics assessments in material handling are a study of how work tasks, equipment, and the environment interact to impact worker safety, comfort, and productivity. The goal of our assessments is to identify potential risks and hazards associated with material handling activities and to make recommendations for improvements to reduce the risk of injury and enhance worker well-being in an effort to also increase efficiency.

PMI Layout Design & Material Flow Service Advantages & Benefits

At PMI, layout and material flow planning are given the importance it deserves. With simplicity at the center of our approach, we function through the principles of:

- Flawless material movement

- Improved visibility for supervisors

- Ensured team safety

- Identifying the least possible wastage

- Inventory optimization and control

When is a Material Flow and Layout Plan Required?

Layout and material planning ensure the optimal and efficient design and movement of materials and staff. There are several circumstances when seeking professional assistance with material flow and factory layout planning will become necessary.

- When working with legacy structures and/or business acquisitions

- Restructuring and reorganizing an existing warehouse or plant

- New Construction

- Drastic changes in manufacturing volume

Industries that Benefit from Layout and Material Flow Services Studies

Automotive Manufacturing

Warehouse and Logistics

Industrial Manufacturing

Food and Beverage

Healthcare and Hospitals

Logistics & Supply Chain

Aerospace

Energy and Utilities

Renewables, Oil, and Gas

Retail

Telecommunications

Architecture

Engineering

Construction

What is a Material Flow System?

Optimizing all material and information flow from end-to-end decreases internal logistics expenses and enhances supply security and versatility.

The material flow process involves multiple steps along a designated path. Material flow systems refer to the transportation of raw materials to finished products through the entire production process.

How does Layout Design apply to Material Flow?

Material flow analysis is crucial in the layout design of industrial facilities as it helps to optimize the flow of materials within the facility. The goal is to minimize waste, reduce handling costs, and improve efficiency. The process involves mapping out the current flow of materials, identifying bottlenecks, and proposing design changes to improve the flow. This may involve rearranging equipment, adding material handling equipment, or creating more efficient work cells. The analysis can also provide data to support decisions related to the storage of raw materials and finished goods. Ultimately, a well-designed material flow system incorporating layout design can reduce lead times, improve quality, and increase profitability.

What is a Material Flow Analysis?

A Material Flow Analysis is a service that involves studying the movement of materials through a production or supply chain system with the goal of optimizing its efficiency, reducing costs, and promoting sustainability. The analysis includes examining the methods, quantities, and effects of human interactions in the material flow process, and providing recommendations for improvement. The end result is a more streamlined and cost-effective material flow system that benefits the business through increased productivity, revenue, and customer satisfaction.

Material Flow Analysis Objectives:

- Efficient material flow

- Sustainable practices

- Lowered operating costs

- Accurate inventory

- Cost-effective inventory management

- Faster order fulfillment

- Increased revenue

- Improved customer satisfaction

- Higher profitability

The process of conducting a material flow analysis can be complex, and it's recommended to use the services of a professional consultant like PMI with extensive expertise.

The process of conducting a material flow analysis typically involves the following steps:

-

Define the scope of the analysis: Identify the boundaries of the material flow system being studied and what data is required to perform the analysis.

-

Collect data: Gather data on the movement of materials in the system, such as supplier information, production processes, inventory levels, shipping and receiving practices, and waste streams.

-

Analyze data: Use statistical and modeling techniques to analyze the data and identify areas for improvement. This includes identifying bottlenecks, inefficiencies, and areas where resources are being wasted.

-

Develop recommendations: Based on the results of the analysis, develop a set of recommendations for improving the material flow system. This may include changes to production processes, inventory management, transportation methods, and waste reduction.

-

Implement improvements: Work with stakeholders to implement the recommendations and monitor progress over time. This may involve making changes to equipment, processes, or organizational structure, and tracking progress through KPIs.

-

Evaluate results: Regularly evaluate the results of the material flow analysis to ensure that improvements are being made and to identify any additional areas for improvement.

Our Experts

PMI's team of experts delivers comprehensive Lean Manufacturing Consulting services with decades of experience in material flow and layout design. Our wide-ranging expertise allows us to effectively serve various markets. Our experts offer tailored solutions based on your specific requirements and industry type, resulting in optimized production processes and detailed improvement reports.

- Carefully selecting the most appropriate techniques based on your specific scenario and objectives

- Applying the best methods for your specific industry type

- Providing detailed optimization recommendations and reports to help improve your processes

Material Flow & Layout Design Media

Speak with one of our Layout & Material Flow Experts!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our Layout & Material Flow representatives NOW?