Simulation of an Automated Closure line for a Leading Supplier – New Body Shop

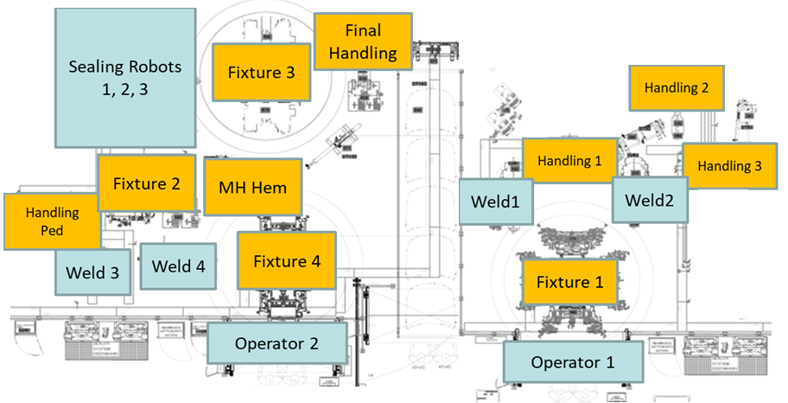

A leading line builder designed a new body shop line for its client in the automobile industry and wanted to check the feasibility of its proposed design and identify minimum buffer sizes to achieve target production

Points

- Automobile Industry

- Tecnomatix Plant Simulation

- Work Cell Simulation

- Bottleneck Analysis

- Downtime Analysis

Client's Challenge

- Check feasibility and validate the proposal

- Identify and alleviate bottlenecks in the system

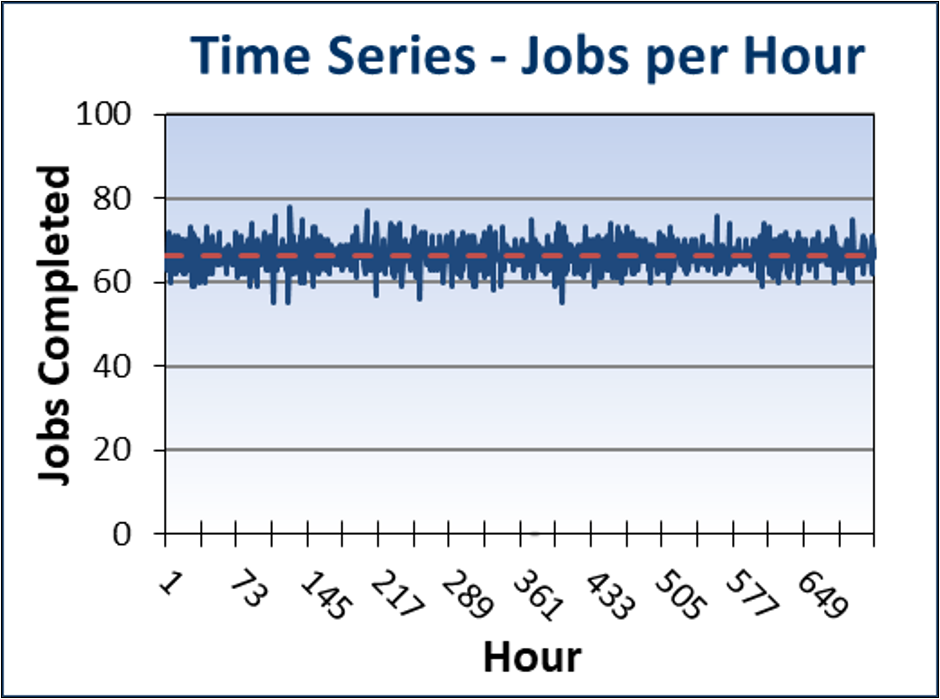

- Identify minimum buffer sizes required to achieve target production

PMI's Approach

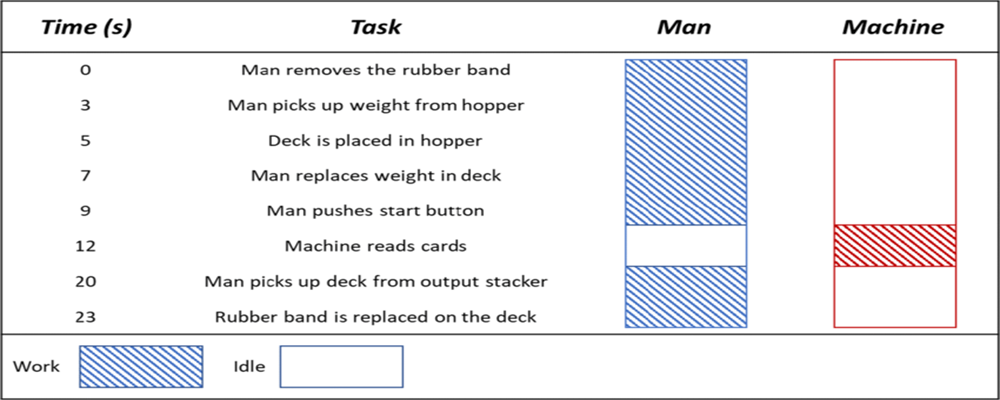

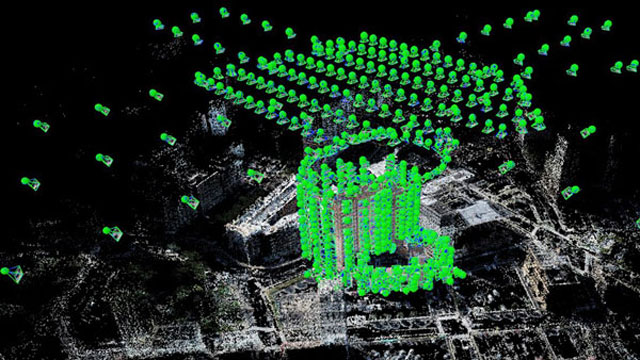

- The detailed process was modeled in Tecnomatix Plant Simulation

- The operating sequences and downtimes from the client were provided through an Excel interface to the simulation

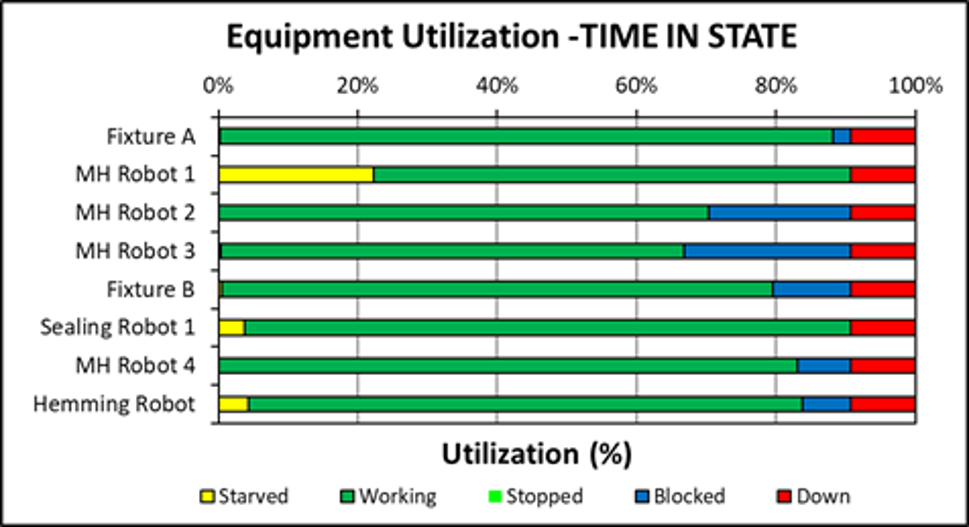

- The buffer variation, throughput and time-in-state graphs were recorded and studied

Findings & Recommendations

The system was operating only at 85% of its designed capacity

We were able to identify the first bottleneck to be the buffer between an assembly and an inspection station

- The minimum buffer requirement was suggested through buffer sensitivity analysis

- The throughput loss due to selecting a smaller buffer was demonstrated

The second bottleneck of the system was the operating sequence of a material handling robot

- The cycle time of the handling robot needed to be reduced or the operating sequence had to be modified

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?

Recent posts