Simulation of a Paint Shop for a Leading Automobile Manufacturer

One of the India’s biggest automotive manufacturers had planned to expand one of its Paint Shops.

The expansion was planned to increase the Paint Shop capacity 1.5 times the existing capacity. Given the complexity of the Paint Shop system, the client wanted to conduct a simulation study to determine whether the proposed expansion can indeed increase the Paint Shop capacity as desired.

Key Points

- Automobile Industry

- AutoMOD

- Plant Simulation

- Bottleneck Analysis

- Carrier Analysis

Client's Challenge

- Determine if the proposed expansion can help increase Paint Shop capacity

- Identify and alleviate bottlenecks

- Understand sensitivity of Paint Shop output to different operational parameters

PMI's Approach

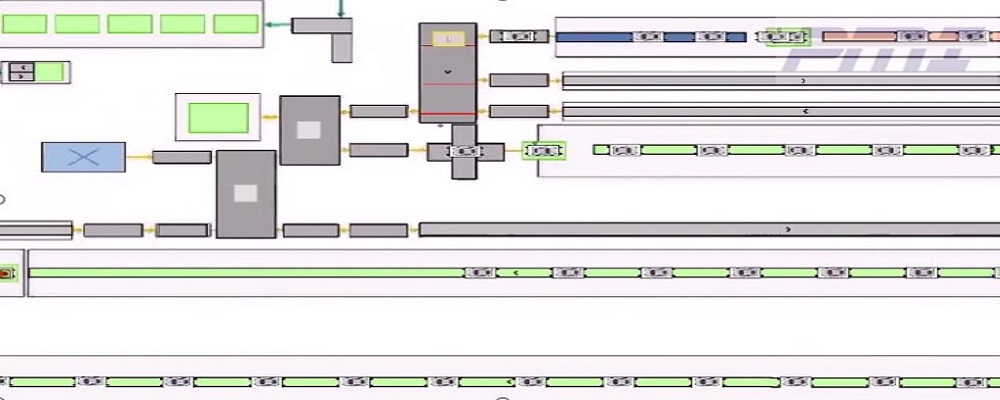

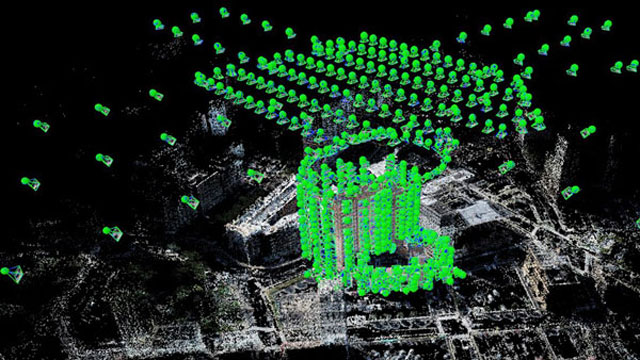

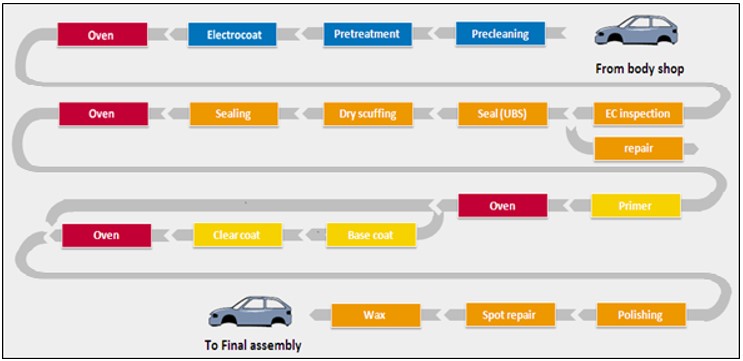

- We developed the detailed process flow in Tecnomatix Plant Simulation

- System throughput, time-in-state graphs, number of vehicles in the system were tracked

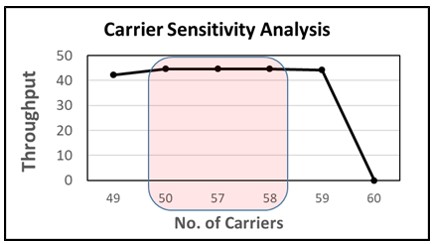

- We performed a number of analyses by varying the repair percentages, storage capacities, model mixes and downtimes

Findings & Recommendations

The first bottleneck in the system was due to an operation rule near the end of an oven

- Improving the cooling zones present after the oven would cool vehicles faster and avoid a few process stations ahead, leading to 15% increase in throughput and equipment reduction as well

We found that the repair percentages after polishing operation were high and caused loss in throughput

- Simulation experimentation showed that additional storage capacity has to be provided or the production quality has to be improved to meet the target production

We found that in order to maintain target production, the model mix limits to be followed for producing its 4 variants

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?

Recent posts