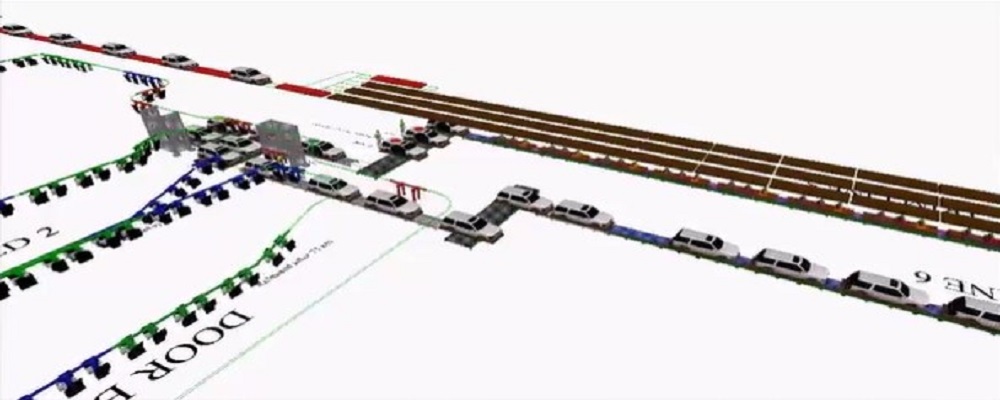

Simulation of a Door Assembly Line for a Leading Vehicle Manufacturer

A leading global automotive company wanted to improve its operations, setup optimum number of carriers in its Door assembly area to meet its increased production target.

Key Points

- Automobile Industry

- AutoMOD

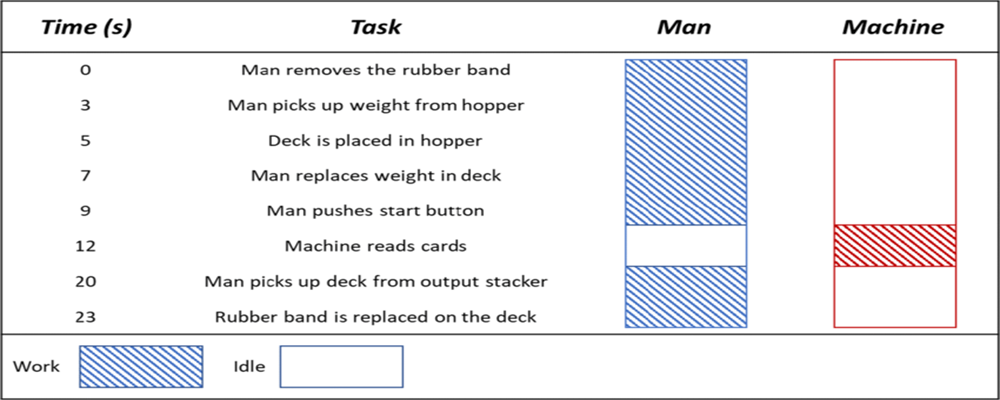

- Bottleneck Analysis

- Buffer Analysis

- Carrier Analysis

Client's Challenge

- Identify and alleviate bottlenecks in the system

- Recommend ideal number of door hangers, buffer sizes and other operational changes to achieve target production

PMI's Approach

- We modeled the detailed door lines and main lines in AutoMOD

- System throughput, time-in-state graphs, number of vehicles in the system were tracked

Findings & Recommendations

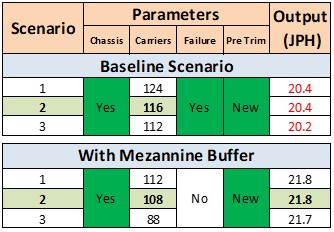

We found that there was loss in production due to downtimes, particularly whenever a specific model type arrived

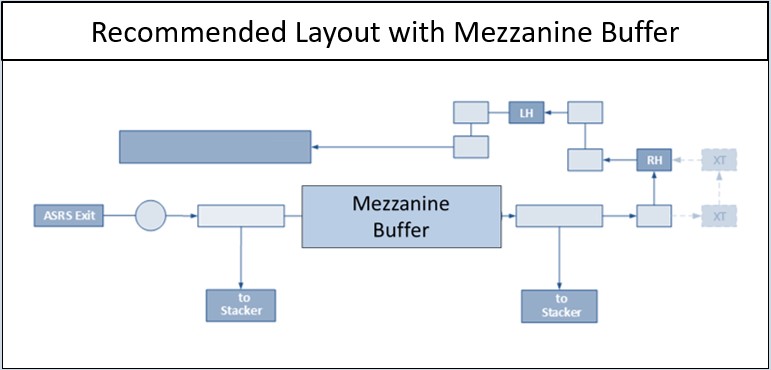

- Recommended addition of a mezzanine buffer just before an unloading station which proved to eliminate blockages caused during downtimes

Due to a routing constraint, a vehicle required 3 minutes of travel time which lead to loss in throughput

- Recommended two more cross transfers to be added in the system before the unloading station

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?

Recent posts