Capacity Validation Study – TCF

Automotive TCFCapacity Validation Study

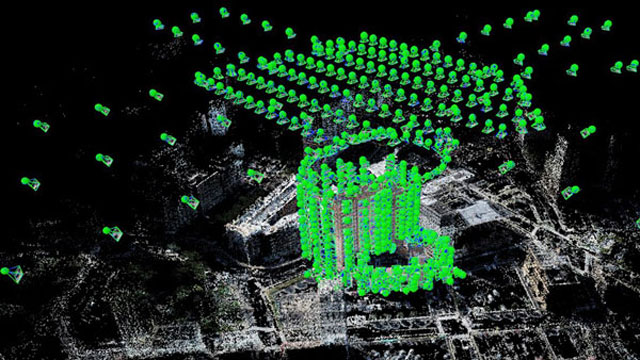

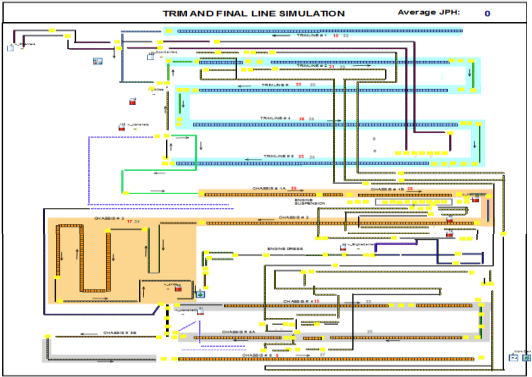

Validating the TCF line to produce target throughput

Key Points

- Multimodel Assembly line

- Subassembly line breakdown effect on

mainline - Throughput improvement roadmap

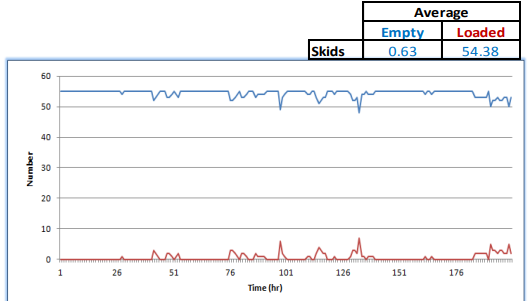

- All types of carriers/hangers (10 types) optimized; outcome used for purchasing

decision

Client's Challenge

- Effect of introduction of new models

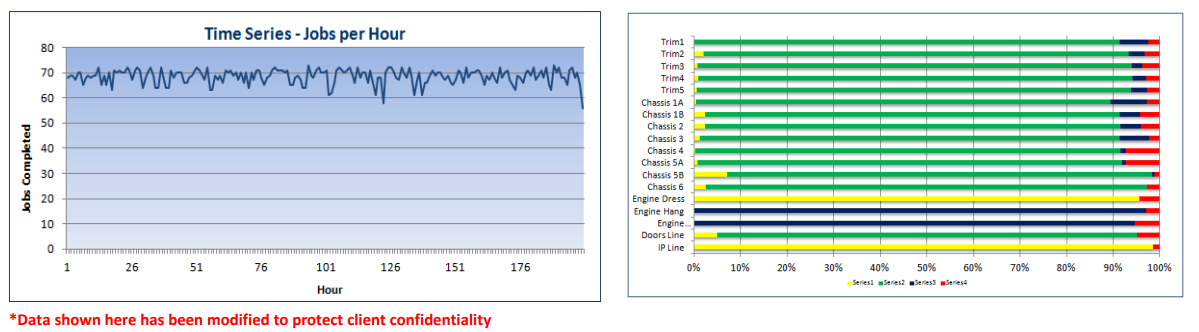

- Amount of blockage in the system due to downtimes

- Optimum number of carriers

- Buffer/ Decoupler capacity

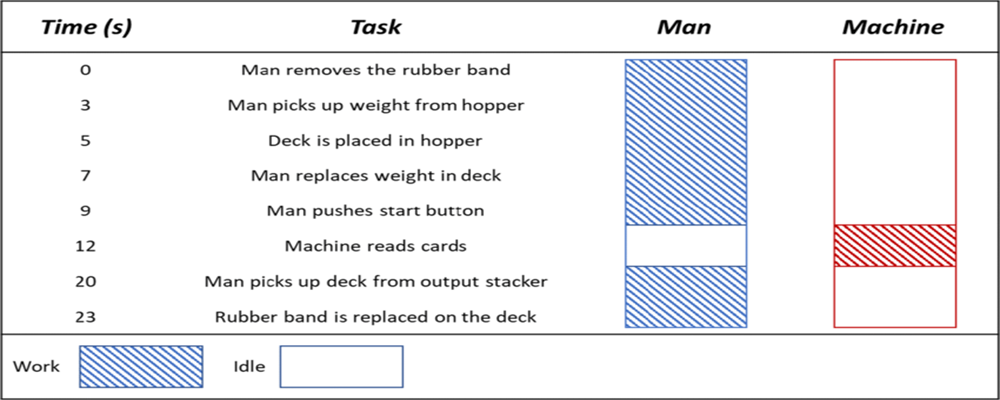

PMI's Approach

- Analysis of Data, building the model, and verification

- Analysis of baseline model results

- Buffer Sensitivity Analysis for some parts of the Chassis

- Carrier optimization for every subassembly

- What-Ifs to reach standard uptime

Findings & Recommendation

- Model was found to fall short of achieving the target

- Number of extra fuel fill equipment determined to reach

desired uptime at Flattop - De-couplers before and after Chassis line 6 were identified as the

bottleneck - What-ifs conducted to find options to meet targets

Let our experts show you how our Services can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?

Recent posts