Capacity Planning in “Build to Order” Sunglass Manufacturing Industry

MANUFACTURING INDUSTRY\Capacity Planning

Capacity Planning in "Build to Order" Sunglass Manufacturing Industry

Key Points

- Huge Variation in Product Mix - Build to Order

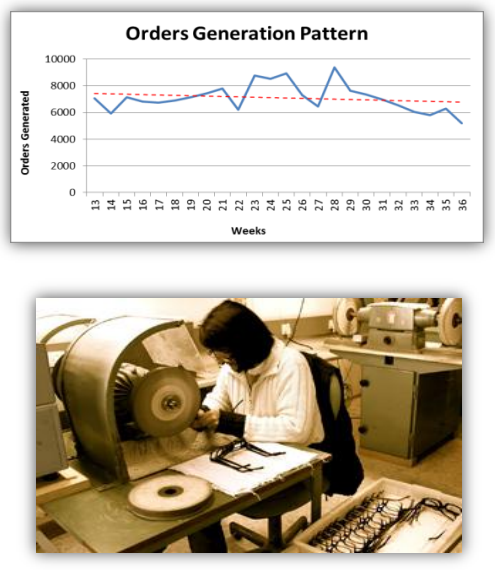

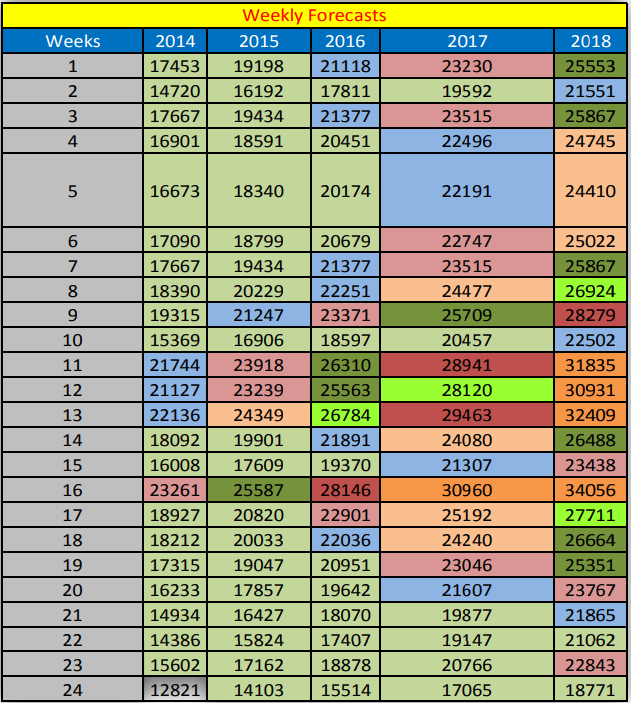

- Large seasonal variation in Demand

- Capacity Planning

Client's Challenge

- N number of variations in the product as it is a Build to order (BTO)

- Immense variations in cycle times due to changes in the property of lenses

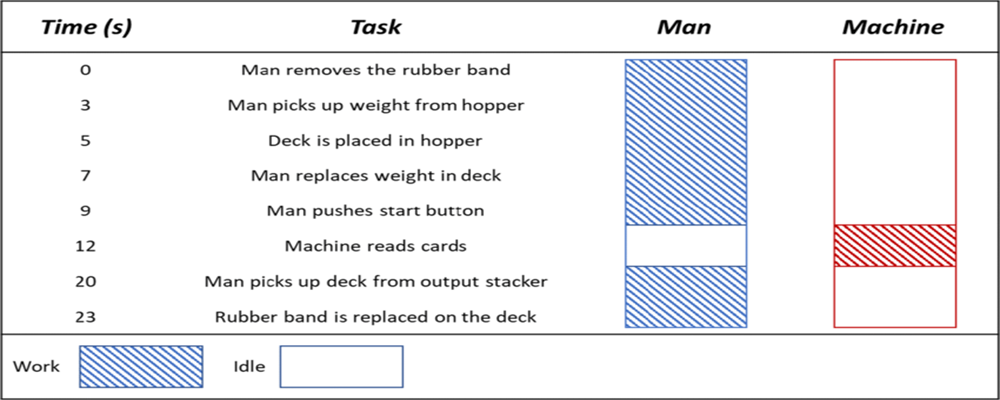

- Manual/Auto Operations operated individually or in batches

- Wide variations in weekly demand throughout the year

- Reduce order lead time to maintain the reputation of on-time delivery

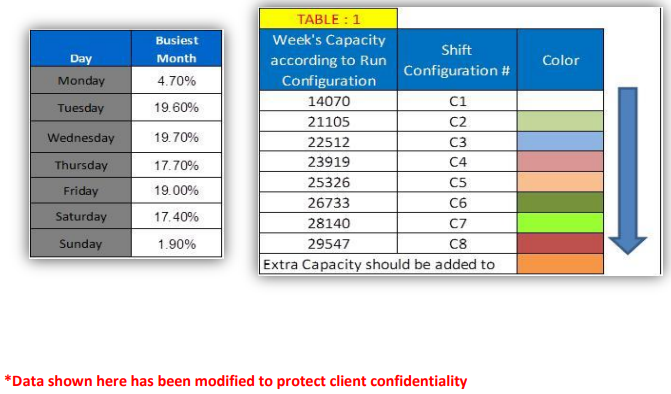

- Predict new shift patterns to meet future demand, if any

PMI's Approach

- Data analysis, 2D model building, verification & validation

- Analysed shift pattern and its effects on weekly throughput

- Used MODAPTS to reduce Process lead time in manual operations

- Integration of shipment schedule within the Model to study Order lead time

Findings & Recommendation

- The study showed current shift pattern can not meet the future demand

- Devised a new shift pattern to meet a future forecast for the next 5 years

- Identified the maximum production limit beyond which capacity expansion is required

Recent posts